Cold Formed Steel Purlin Design with SkyCiv Software

What is a Steel Purlin?

Cold-Formed Steel Purlins are longitudinal beams installed to brace together trusses or rafters. Its primary function is to transfer external loads applied on the roof to the top chord of the truss. The design of purlins is idealized from a pin-connected structure where the distance of the trusses is treated as the span and its ends as its joints. Gravity and wind loads are commonly applied on the purlin and will cause the member to sag. In order to provide lateral support for the purlins, sag rods are added on discrete points.

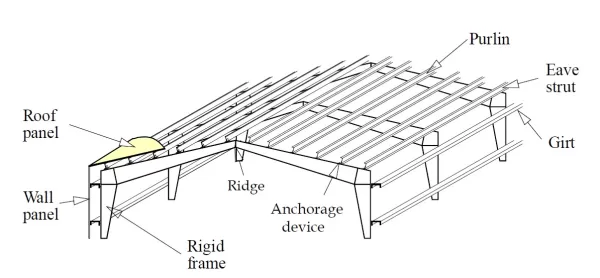

Aside from being used in roofing systems, purlins can also be applied as girts for wall cladding. The image below shows a typical steel framing applied with purlins.

Figure 1: Typical Metal Building Framing (Retrieved from AISI Design Guide D111-09)

Common Types of Cold-Formed Roof Purlins

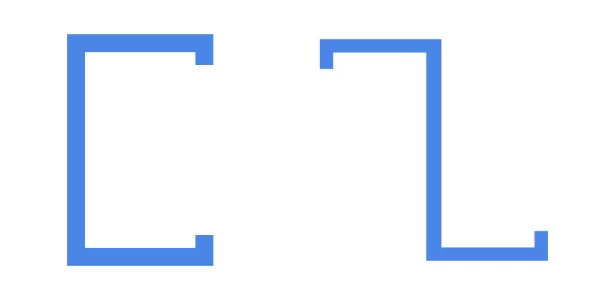

C and Z sections are the most common shapes available for cold-formed steel purlins. As their names imply, these sections are bent according to the letter in the alphabet (refer to Figure 2). Z Purlins are point-symmetric, and sometimes their flanges are manufactured slightly unequally to allow overlapping. Meanwhile, C Purlins have a slightly lesser vertical section modulus, making them more advantageous for roofs with lower slopes. Each shape has its own pros and cons; it’s up to the engineer to assess the appropriate purlin based on the project requirements.

Figure 2: Common C and Z shaped-purlins

When installed on the roof, purlins are generally lapped with each other, providing continuity in the section. It is usually connected using machine-grade bolts through the webs of lapped purlins.

When it comes to its design, loads are applied on the normal and tangential axes of the section’s centroid. Thus, biaxial bending is mainly checked. Torsional effects on the member are assumed to be neglected due to the partial lateral and torsional restraints provided by the roof sheathing.

Advantages of Cold-formed Steel over Other Materials

This article focuses on the use of cold-formed steel (CFS). This type of steel is made from thin gauge sheets and, from the word itself, is made by cold working processes such as pressing and rolling, making it more durable as compared to hot-rolled sheets. In contrast with wood, cold-formed steel offers a longer lifespan as it is resistant to mold or vermin.

Since it is lightweight, CFS is easier to install and can even be recycled when the roofing system is removed or changed. When correctly constructed and designed, CFS structures can resist extreme environmental loads making it one of the most resilient materials available.

Using the SkyCiv Purlin Capacity Calculator

With the SkyCiv Purlin Load Capacity Calculator. Calculations are patterned primarily from AISI, ASCE, and AISC codes. Unlike typical manufacturer’s capacity tables for purlins, this calculator presents a simplified approach to checking the section’s capacity considering its geometric and material properties, roof configuration, and loads.

This calculator enables the user to input standard and custom C and Z purlins. It also requires input for the bay length, which is the purlin span, the purlin spacing, roof angle, and the location of the sag rod, which is either at the midpoint or at third points. Load cases adapting the ASD design approach are also used to complete its analysis.

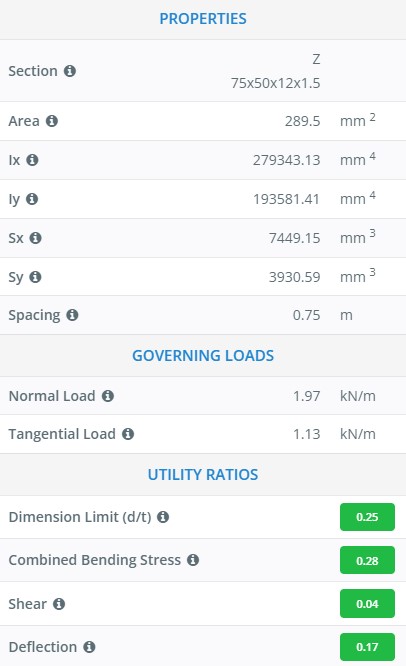

The figure below shows the sample output of the calculator:

Figure 3: Purlin Capacity Calculator Output

Here the purlin properties are shown together with the purlin spacing specified by the user. Also presented are the governing loads computed from the most critical load combination. The purlin capacity is characterized by the combination of utility ratios from the dimension limit, combined bending stress, shear stress, and deflection.

Check out the Purlin Spacing and Capacity Calculator and design your roofing system today!

References:

- Design Guide for Cold-Formed Steel Purlin Roof Framing Systems (AISI Design Guide D111-09) . American Iron and Steel Institute, 2009.

- Segui, William T. Steel Design 6th Edition. Cengage Learning, 2018.

Product Developer

BSc, MEng (Civil)