This article will give some background and brief insight on the history of piles and go over the advantages and disadvantages of Concrete Piles, which can be designed using SkyCiv’s Foundation Design module.

What is a concrete pile?

A concrete pile is a foundation driven deep into the ground to support the structure, unlike shallow or wide foundations such as Isolated Footings or Combined Footings. They are usually much thinner in diameter or width than in length. Due to their sometimes incredible length/depth, piles typically carry a higher load capacity than the aforementioned shallow footings.

With most structures, concrete piles are more common than the other piles. The earliest form of the concrete pile is a cast-in-place pile. Further advancement in construction technology led to the creation and adoption of precast piles and, eventually, prestressed piles. All three concrete piles are viable options in today’s construction.

What are other types of piles?

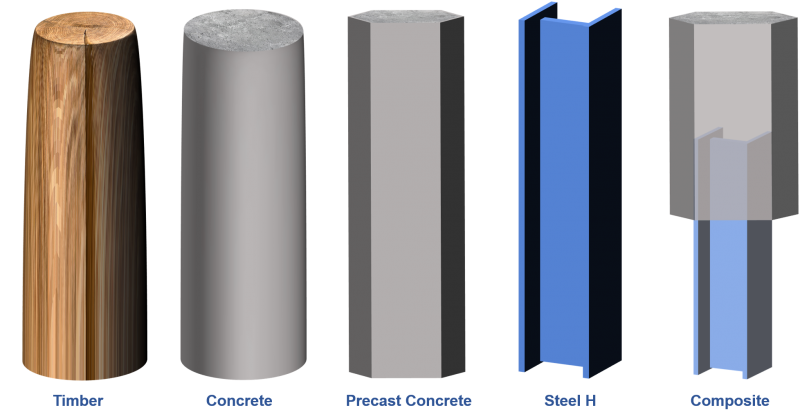

Traditionally, timber or wood can be used as piles and are commonly used to support small structures or bridges in weak soils. Some larger structures still use timber piles, such as jetties, but timber piles bear some limitations. First, timber is prone to deterioration or decay over time, increasing the uncertainty in its lifespan. Another drawback is the limited available length of timber that can be produced from the tree being cut down due to its actual length. Subsequently, it is not advisable to join two timber trunks together to combat this length issue.

Steel H-piles became a common substitute for concrete piles. They can withstand heavier loads and may eliminate some installation issues compared to concrete piles. The process of importing and pouring concrete may not be doable in some environments, so the steel pile is used. However, concrete piles are preferred to use in locations with corrosive soils than steel piles.

A composite pile may be a combination of two different materials, most commonly steel and concrete. This type of pile is usually used when the required length for bearing capacity exceeds the capacity of a simple concrete pile. Composite piles are rarely used as the installation is complex, and it is challenging to provide a proper joint between the materials.

Figure 1: Rendering of various pile types

When and why use concrete piles?

One of the most common situations in which concrete piles are used is when the top layers of the site’s soil are very weak and cannot support the structure, usually characterized by wet, clay-like soil. In this case, piles bypass these weak ground conditions and transfer the building loads to a more stable layer of soil beneath, like bedrock. Another reason to use concrete piles is when the building loads are large and cover a small footprint. Examples include high-rise structures or skyscrapers, large bridges, and water tanks.

In terms of material and mechanical properties, concrete piles provide high structural capacity and more durability, especially in corrosive and marine environments, than steel piles. However, concrete is not as flexible as steel. It can be easily be damaged during driving and requires larger lifting equipment. Despite this issue, concrete piles remain the most common type.

Types of concrete piles

Concrete piles are categorized into two types: cast-in-place piles and precast piles. Cast-in-place piles can be further identified as cased or uncased piles. Conversely, precast piles can either be a typical reinforced concrete pile or a prestressed pile.

Cast-in-place piles

Generally, cast-in-place piles are more commonly used than precast piles. This type of pile is more advantageous than precast piles due to ease of handling and the elimination of any storage requirements. There is a chance for damage upon handling when moving precast piles, and they need to be stored on site. Uncased piles offer a more economical cast-in-place pile, while cased piles offer a more secure and accurate concrete placement.

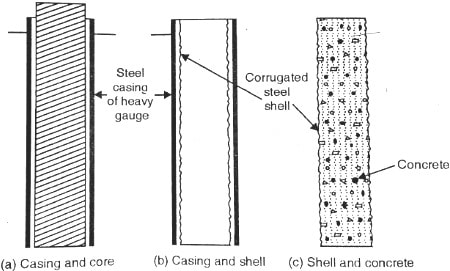

Cased cast-in-place piles use a cylindrical or tapered thin-walled steel tube that serves as the form or mold for the concrete, which lines the bored hole where the pile is housed. This type of pile is more desirable as it allows inspection of the pile before the pouring of concrete. The casing leads to a cleaner and more dependable pour, without irregularities. Cased cast-in-place piles are better in nearly every soil condition. Some common examples of cased cast-in-place piles include:

- Raymond piles

- Mac-Arthur piles

- Union metal monotube pile

- Swage pile

- Western button bottom pile

Figure 2: Breakdown of a Mac-Arthur pile

Source: theconstructor.org

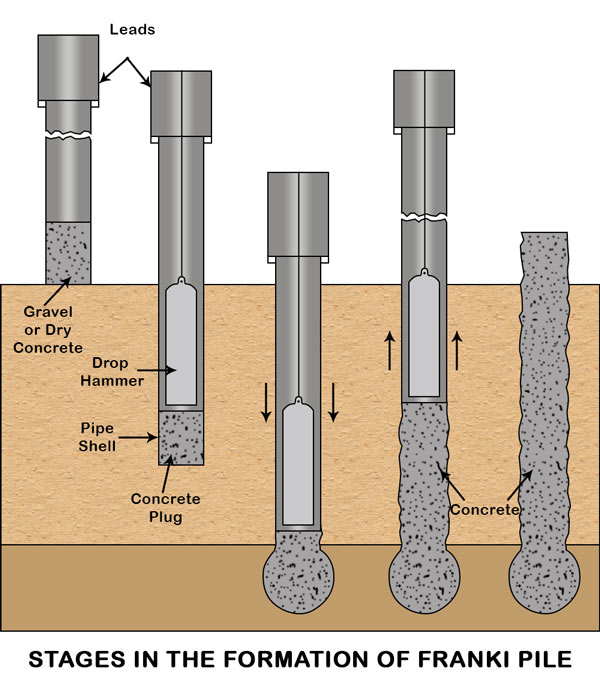

Uncased cast-in-place piles are more economical and practical than cased piles. However, caution and inspection are required during installation because of the direct contact with soil. It is recommended to use only on highly cohesive soils. With non-cohesive soils, there is a risk that the soil or water breaks into the pile. Water could seep through the concrete cracks and degrade the reinforcement. The following are the different types of uncased cast-in-place piles:

- Simplex pile

- Frankie pile

- Vibro pile

- Pedestal pile

cc

Concrete piles share the same pros and cons as other concrete structural members. The following advantages and disadvantages mainly focus on the installation of cast-in-place piles and differences with the precast piles:

Advantages of cast-in-place piles:

- Creates less vibration during installation

- Piles of any size and length can be fabricated on site

- Requires less or no large equipment as compared with precast piles

- It does not significantly disturb the surrounding soil

Disadvantages of cast-in-place piles:

- Installation time is often longer due to the setting up and removal of forms and concrete curing time.

- Installation requires intensive labor.

- Careful supervision is needed to maintain good workmanship and quality control.

- Requires storage for the equipment or the materials to be used

- Weather and site conditions are evaluated before installation

Precast piles

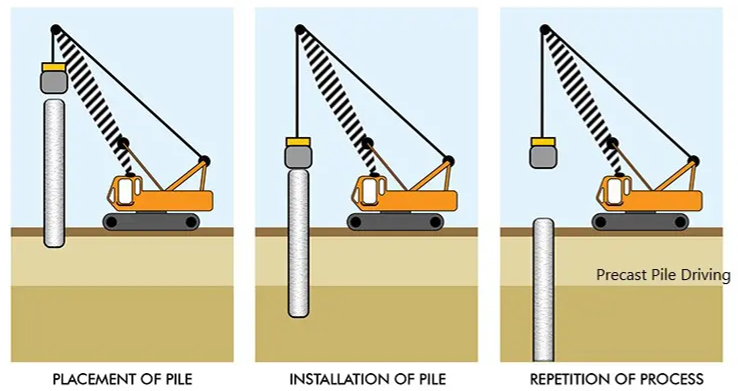

Precast piles are constructed by hammering or driving the pile into the soil using large driving equipment, as shown in figure 4. They are more versatile and suitable to use in most soil conditions. These are also used where the foundations need to extend above water or ground level. Precast piles are manufactured off-site in a controlled environment with uniform or tapered cross-sections and may be cast in circular, square, or octagonal shapes. The deep end of uniform cross-section piles is sharply tapered and secured with a cast steel shoe to protect the pile and help penetrate hard strata during driving. Precast piles with larger widths are usually manufactured with hollow cross-sections to reduce their weight and increase the effectiveness of the driving of the pile.

Figure 4: Pile driving of Precast Pile using a vibrating piling machine

Source: structuralguide.com

Advantages of precast piles:

- Can carry relatively higher working loads

- Well suitable for marine installations

- Can extend above ground or water

- Manufactured in a controlled environment — more certainty on overall quality.

- Highly resistant to biological and chemical actions of subsoil

Disadvantages of precast piles:

- Requires special equipment for handling and transporting

- Precast piles are heavy and need machinery to transport and move around the site

- Challenging to increase or excessive cut-off length

- The length of the pile may be limited due to storage or transportation

- High initial cost

SkyCiv Foundation module offers an innovative and user-friendly interface for the design and analysis of a single pile in accordance with ACI 314-2014 or AS 2159(2009) & 3600(2019).

Want to try SkyCiv’s Foundation Design software? Our free tool allows users to perform load-carrying calculations without any download or installation!

Product Developer

BSc (Civil), MSc (Civil)