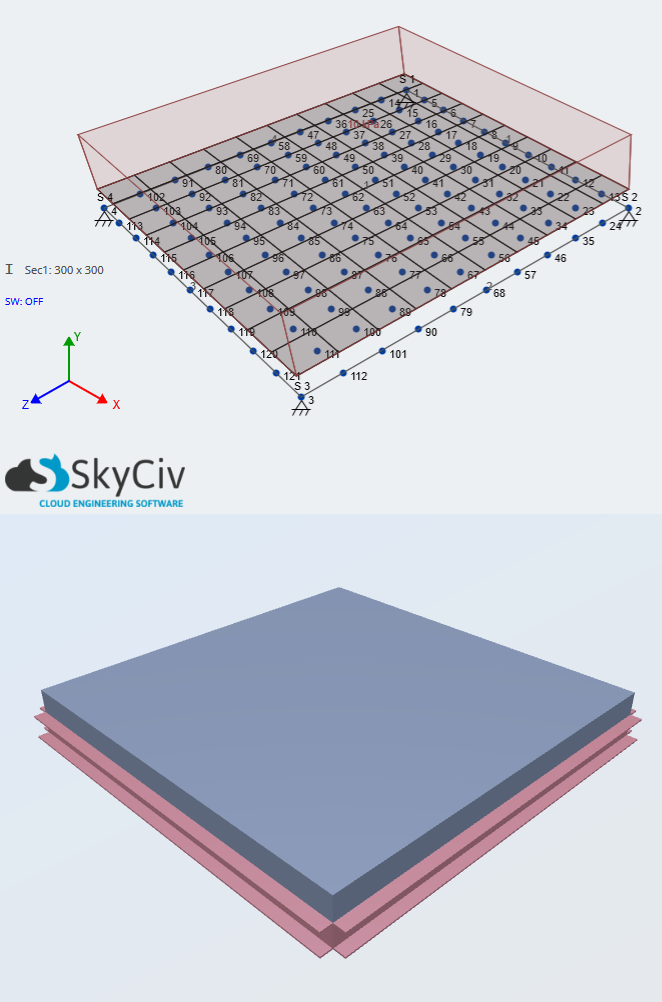

Model Details and Parameters

The purpose of this test case is to validate the plate/shell element solver in SkyCiv Structural 3D (S3D). The results were compared against a third-party analysis software. In this test case the following model parameters were used:

- Analysis Type: Linear Static

- Beam Material: Structural Steel

- Beam Young’s Modulus: 200,000 MPa

- Beam Poisson’s Ratio: 0.27

- Slab Material: Concrete

- Slab Young’s Modulus: 17,000 MPa

- Slab Poisson’s Ratio: 0.20

- Plate Type: Mindlin Plane Stress

- Plate Size: 5m x 5m (offset 300mm to sit on top of the beams)

- Plate Thickness: 300 mm

- Corners Supports: FFFRRR (3D Pin) on the four corners

- Pressure Load: 10 kPa normal to plate

- Members: 5m Length, 300mm x 300mm x 20mm

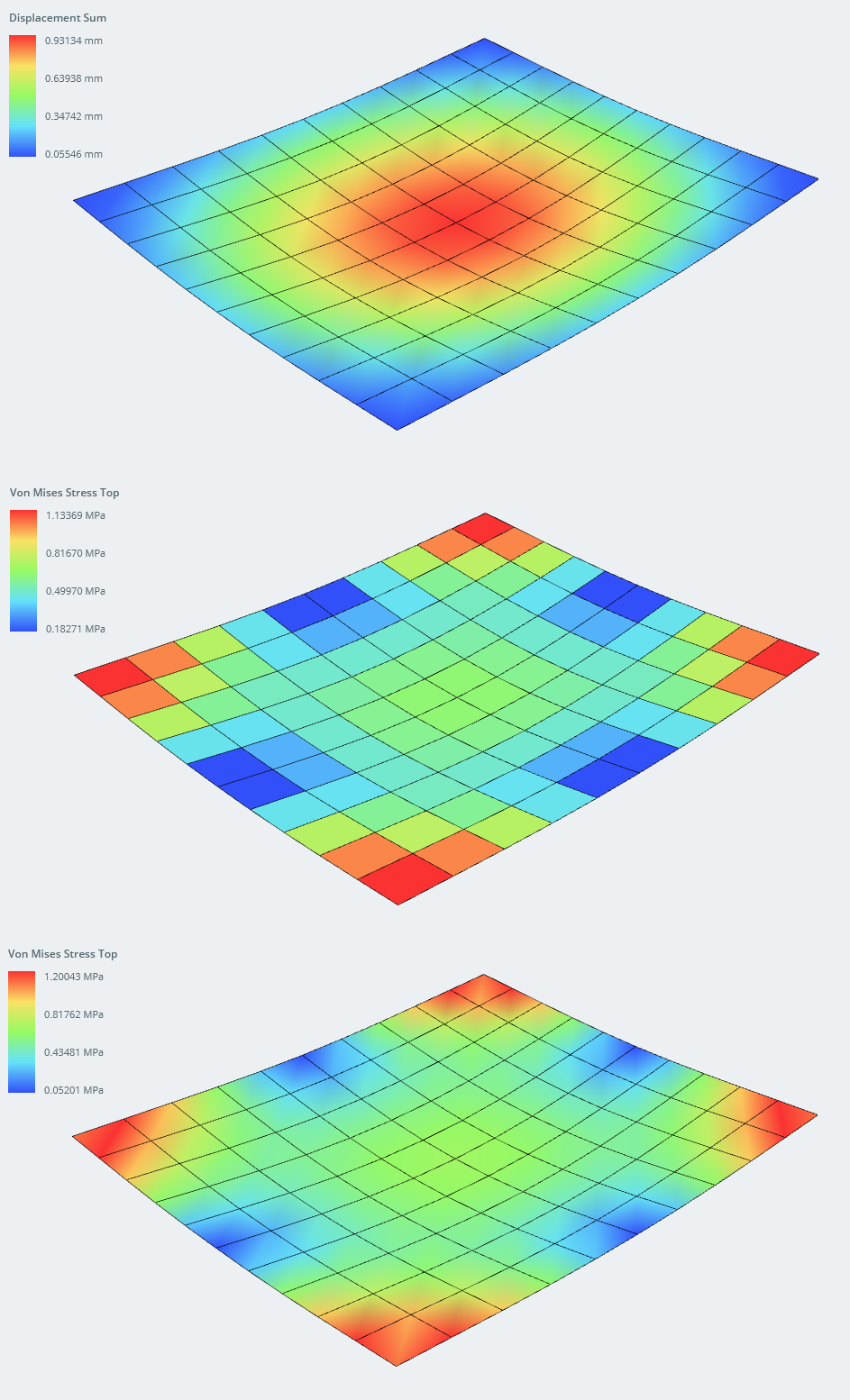

Results – 10×10 Structured Mesh

| Result | Location | SkyCiv | Third-Party 1 | Difference 1 | Third-Party 2 | Difference 2 |

| Max Member Displacement Y (mm) | Node 69 | -0.26661 | -0.26625 | 0.14% | -0.26660 | 0.00% |

| Max Plate Displacement Y (mm) | Node 58 | -0.93134 | -0.92789 | 0.37% | -0.93132 | 0.00% |

| Max Von Mises Stress – Element (MPa) | Meshed Element 1 Top – Underside of Slab | 1.13369 | 1.12261 | 0.99% | 1.13930 | -0.49% |

| Max Shear Stress, Tresca – Element (MPa) | Meshed Element 1 Top – Underside of Slab | 0.62417 | 0.61864 | 0.89% | 0.62760 | -0.55% |

| Reaction Y (kN) | Node 1 | 62.50000 | 62.50000 | 0.00% | 62.50000 | 0.00% |

| Reaction X (kN) | Node 1 | 114.15130 | 115.52470 | -1.19% | 114.15270 | 0.00% |

| Member Moment Z (kN-m) | Node 1 | -8.97004 | -8.46763 | 5.93% | -8.97015 | 0.00% |

Extra Considerations

- This verification model was created and checked on 28 February 2020. Since this date, the plate solver and S3D software may have been further improved to achieved greater accuracy.

- Plates are not exact elements like beam and frame elements and therefore the mesh plays a huge role in the results. Always try to use a structured mesh when it is possible to do so.

- Results between software will never be exactly the same since different elements are used and the nature of plates are approximate