How to Design Pile Foundation?

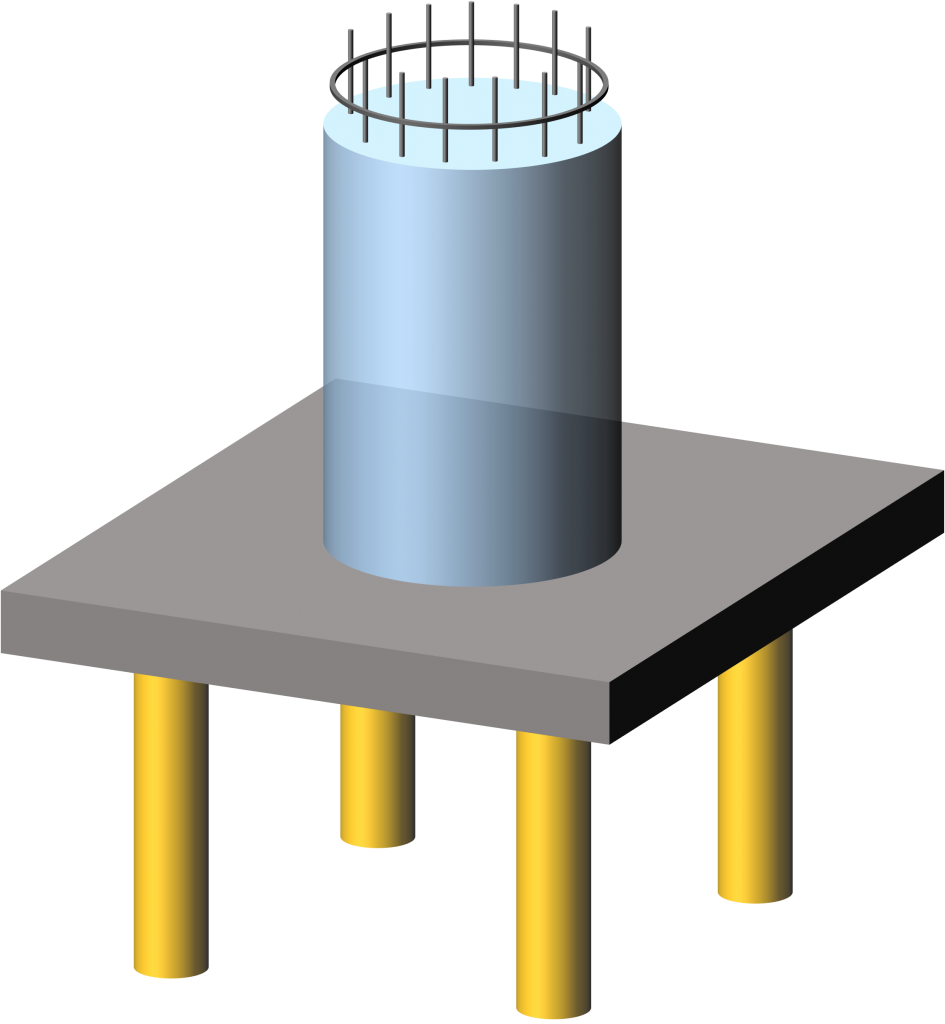

A deep foundation, such as a pile, is a structural member that transmits loads from the superstructure to bedrock or a stronger layer of soil. Pile is a type of foundation that can be made of steel, concrete, or timber. In terms of cost, piles foundation costs are higher than shallow foundations. Despite its cost, piles are often necessary for structural safety purposes.

When can we use Piles?

Weak soils

If the upper soil layers are too weak or highly compressible to support the loads transmitted by the superstructure, piles are used to transfer these loads into a stronger layer of soil or onto a bedrock. Piles that transmit loads into a bedrock are called end-bearing piles. This type of pile solely relies on the load-bearing capacity of the underlying material at the tip of the pile. On the other hand, when bedrock is too deep, piles can transmit the loads through the surrounding soil gradually by friction. This type of pile is called a friction pile.

Horizontal forces

Piles are a more suitable foundation for structures subjected to horizontal forces. Piles can resist horizontal actions through bending while being able to transmit vertical forces from the superstructure. This is a typical situation for designing earth-retaining structures and tall structures subjected to high wind or seismic forces.

Expansive or collapsible soils

Swelling or shrinking of soils may add a considerable amount of pressure to the foundation. It occurs on expansive or collapsible soils due to the increase or decrease in moisture content. It may also cause more damage for shallow foundations; in this case, piles can be used to extend the foundation beyond the active zone or where the swelling and shrinking might occur.

Uplift forces

Uplift forces are developed as a result of hydrostatic pressures, seismic activity, overturning moments, or any forces that may cause the foundation to be extracted from the ground. It is common on structures such as transmission towers, offshore platforms, and basements. In this situation, pile foundation is considered to resist these uplift forces.

Soil erosion

Soil erosion at the ground surface may cause the loss of bearing capacity of the soil.This may severely damage structures with shallow foundations.

How Do We Estimate the length of the pile?

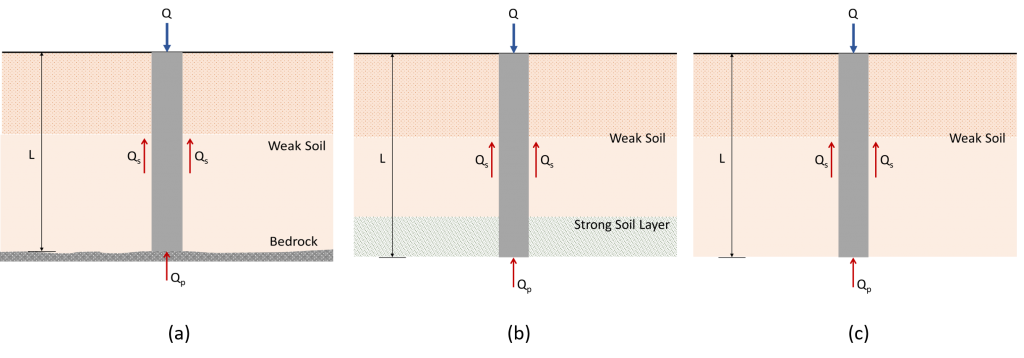

Soil investigation plays a significant role in the selection of pile type and estimation of the necessary length of the pile. Estimating the length of pile requires good technical judgement on the geotechnical site data. It can be classified depending on the load-transfer mechanism from the structure to the soil: (a) end-bearing piles. (b) friction piles, and (c) compaction piles.

End-bearing piles

The ultimate load capacity of end-bearing pile depends on the load-bearing capacity of the underlying material at the tip of the pile. The necessary length of this type of pile can easily be estimated by determining the location of bedrock or a strong layer of soil as long as it is at a reasonable depth. For instances where a hard stratum is present rather than bedrock, the length of the pile can be extended for a few more meters into the soil layer, as shown in Figure 2b.

Friction piles

Friction piles (Figure 2c) are used when the bedrock layer or hard stratum doesn’t exist or located at unreasonable depth. In that case, the use of end-bearing piles become very long and uneconomical. The ultimate load capacity of friction piles is derived from the skin friction developed along the length of the pile and the surrounding soil. Length of friction piles is relative to the shear strength of soil, applied load, and pile size.

Compaction piles

Compaction piles are a type of piles which are driven through granular soils to achieve proper compaction of soil near the ground surface. Length of compaction piles depends mainly on the relative density before and after the compaction, and the required depth of compaction. Compaction piles are generally shorter than the other types of piles.

Load Transfer Mechanism for Piles

Consider a loaded pile with length L and diameter D, as shown in Figure 2. The load Q on the pile shall be resisted mainly by the soil at the bottom of the pile Qp., and partly by skin friction developed along the shaft Qs. Generally, the ultimate load-carrying capacity (Qu) of a pile can be represented by the sum of the load resisted at the tip of the pile and the load resisted through skin friction, or as shown on equation 1.

Qu = Qp + Qs (1)

Qu = Ultimate load-carrying capacity

Qp = End-bearing load capacity

Qs = Skin-frictional resistance

However, for end-bearing piles, load Q is mostly resisted by the soil below the tip of the pile and skin frictional resistance is minimal. On the other hand, the load Q on friction piles is mostly resisted only by the skin friction rather than the end-bearing capacity Qp. Ultimate load capacities for end-bearing and friction piles are on equations 2 and 3, respectively.

Qu ≈ Qp (2)

Qu ≈ Qs (3)

How do we design piles?

The design and analysis of deep foundations such as piles is somehow a form of art because of all the uncertainties involved in interpreting geotechnical data. Although numerous theoretical and experimental approach was conducted to analyze the behavior and estimate the load-carrying capacity of piles in various soil types, but yet, we still have a lot to understand on the mechanism of piles foundation. Fortunately, with the advancement in structural engineering, there is various software that we can use to minimize these uncertainties and reduce calculation time.

The following are some of the processes we can follow to design a piles foundation:

Geotechnical report data

As discussed earlier, pre-foundation design data, such as pile type, length, and size, are pre-determined based on geotechnical report data. Some of the critical parameters which are necessary for further piles foundation design and analysis are the soil types, unit weight, shear strength, modulus of subgrade reaction, and groundwater data

Structural analysis

Recent developments in structural engineering include structural design software which aims to enhance our skills as structural engineers and produce safe designs, especially with complex structures. There is various FEA software that we can use to model our structures and generate reactions, shear forces, and bending moments of the supports from the superstructure. The resulting data shall be then used for foundation design and analysis.

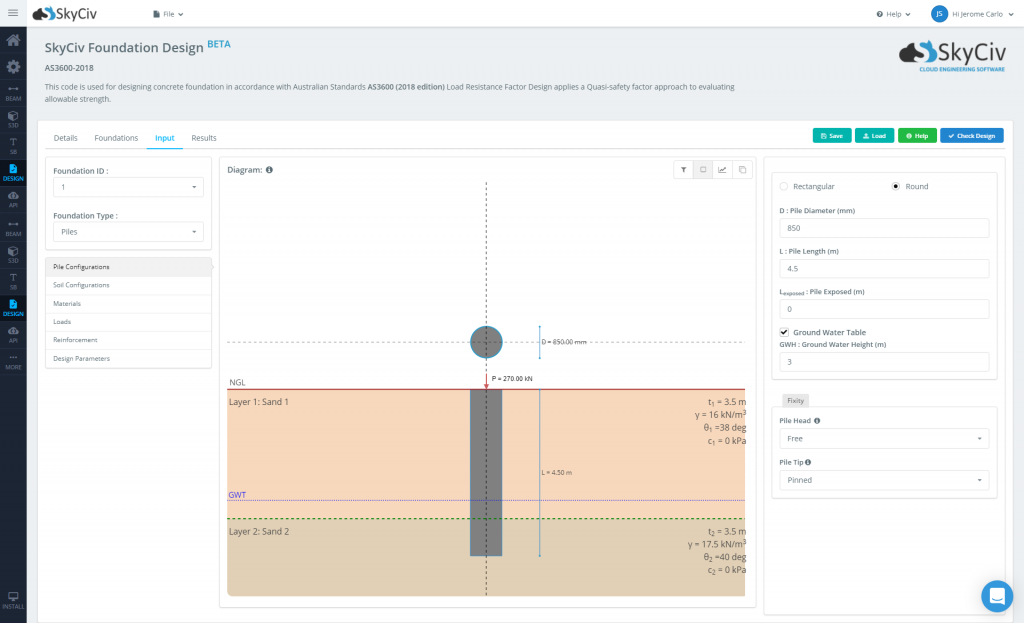

Foundation design

Similar to the FEA software we used to analyze and generate support reactions of the superstructure, there is also numerous foundation design software which we can use to design piles foundation in accordance with different design codes. (note: for a simplified calculator, try our free concrete footing calculator).

Foundation design software for piles requires various input to perform design checks. It includes geometry data, soil profiles, material properties for concrete and steel reinforcements, reinforcement layouts, design parameters specified by the design codes, and the reaction data exported from the structural analysis software.

Some of the standard design checks that are performed for the design of piles foundation:

Geotechnical capacity check is completed when the end-bearing capacity of the soil is determined by dividing the applied vertical loads by the load-carrying capacity of the soil. The ratio should not exceed a value of 1.0. Laterally loaded piles are also checked by estimating the values of the ultimate and allowable lateral loads.

Structural capacity checks are performed by determining axial, shear, and flexural capacities in accordance with the chosen design code. Although for a pile foundation, geotechnical failure is more likely to occur than structural failure, it is still necessary to perform this check for safety measures.

Optimization

A structural engineer should always prioritize safety in designing any type of structure. However, engineers may also optimize their design by experimenting with different pile sizes, and reinforcement layouts, resulting in a reduced total amount of materials and the overall cost of the structure without compromising safety and still maintaining the minimum standards required by the code.

Summary

The process of designing piles foundation generally involves good interpretation of geotechnical site data, modeling and analysis of the superstructure through an FEA software, generating support reactions, foundation design checks, and optimization to come up with a safe and economical design.

Free Concrete Footing Calculator

I hope this tutorial has helped you understand more about pile foundation design. Check out our Free Concrete Footing Calculator, a simplified version of SkyCiv Foundation Design Software, or sign up today to get started with SkyCiv software!