Difference between Reinforced Concrete and Prestressed Concrete

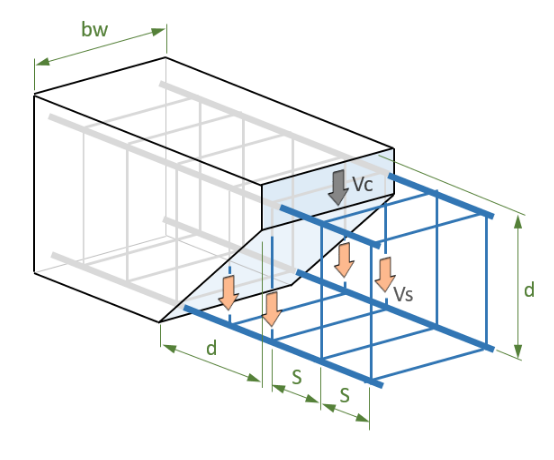

Reinforced concrete and prestressed concrete are both reinforced with longitudinal and transverse steel bars, also known as rebar. The main function of the reinforcement is to strengthen concrete when it undergoes tensile stress.

Let’s take a look at the differences between the two composite materials and their uses.

Reinforced Concrete

1. What is reinforced concrete?

Reinforced concrete, or RC, is a composite material used in construction. The low tensile strength and ductility of the concrete are fortified by the addition of reinforcing steel bars having higher tensile strength and ductility. During construction, steel bars are placed inside formwork before concrete is poured. Rebar can also be wired together into a steel cage arrangement beforehand. Concrete is then poured into the formwork and vibrated to remove air voids in the fresh concrete and ensure consolidation of the aggregates within the concrete mixture. It is imperative that the concrete completely surrounds each bar to ensure a strong bond.

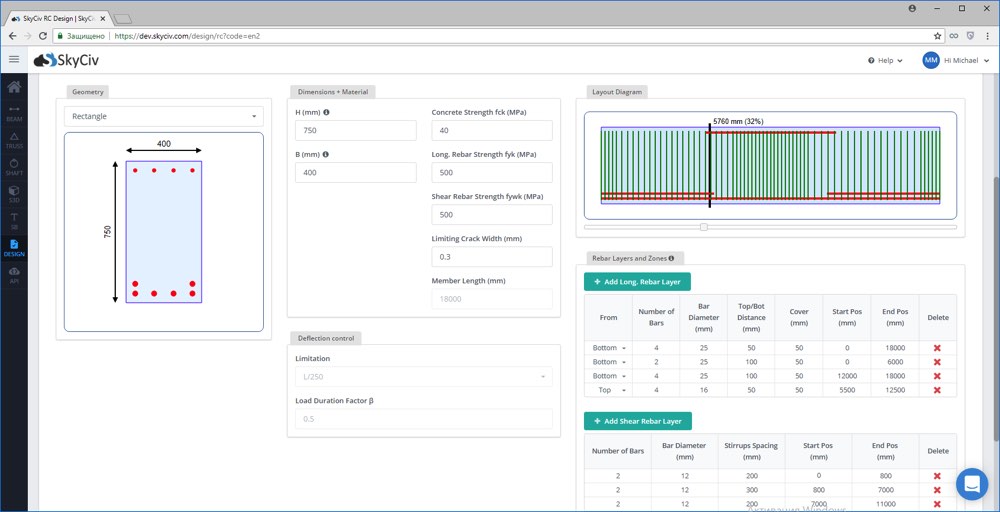

Figure 1: Rectangular concrete beam, with steel rebar is an example of a reinforced concrete member

2. The uses of reinforced concrete

Reinforced Concrete is widely used due to its workability, strength, and availability of its raw materials. It is mainly used as the main members of a particular structure such as columns, piers, piles, beams, slabs, and footings for buildings, houses, dams, bridges, and other similar structures. Reinforced concrete is easily configured to unconventional shapes because it fills the container that it is supporting. This leads to extravagant architectural structures that would otherwise be difficult to build with other materials such as steel and wood. Reinforced concrete is also typically used in public works construction of highway paving and sidewalks. Reinforcing the concrete with steel bars gives the composite section tensile strength that allows for a robust and useful composite building material.

Prestressed Concrete

1. What is prestressed concrete

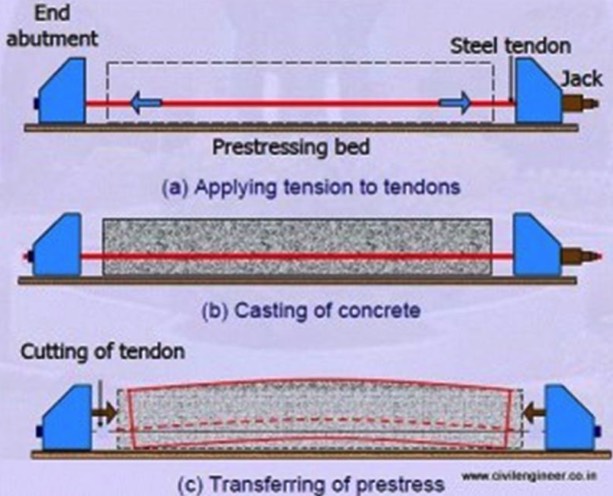

Simply put, it is concrete formed under stress. Reinforcement bars are placed in a form and stressed by the stretching of the bars at each end, inducing tension in the bar. Concrete is poured into the form and all around the bars while they are still being stretched. When they are released, the steel tries to resume its original, shorter, length, and adds a compressive force to the concrete laterally, giving it the strength to span longer distances than normal reinforced concrete.

2. The uses of prestressed concrete

Prestressing is used to make composite beams and piers in large-scale construction such as highway overpasses and commercial buildings. It enables a concrete beam to support weight between piers on either side; without such reinforcing, concrete’s lack of tensile strength would cause it to collapse without support in the middle.

Here are three major implementations of prestressed concrete:

- Pre-Tensioned Concrete: Concrete is cast around steel bars or cables under tension. The concrete naturally bonds to these “tendons” while it cures. Compression by static friction transfers the tension to the concrete once it is released. Subsequently, any tension on the concrete transfers readily to the tendons. Pre-tensioned concrete elements are common in floor slabs, beams, and lintels.

- Bonded Post-Tensioned Concrete: Compression is applied in situ during curing. A duct of aluminum, plastic, or steel is used in casting and follows the area where tension would occur in the concrete. Tendons are pushed through the duct, then tensioned via hydraulic jack after hardening. Once the tendons’ stretching meets design specifications, they are wedged in place and the duct is grouted.

- Unbonded Post-Tensioned Concrete: Here, the individual tendons retain freedom of movement relative to the concrete. Tendons are prepared with a coating of lithium-based grease, then given a plastic-based “shell”, formed through an extrusion. The steel cables are tensioned against anchors placed in the slab’s perimeter. This design provides the ability to de-stress the embedded tendons prior to repair.

Figure 2: Simple diagram of a prestressed concrete.

SkyCiv Reinforced Concrete Design Software

SkyCiv offers an easy-to-use reinforced concrete design software to help analyze and design reinforced concrete members. Using SkyCiv Beam Software, you can analyze the loads on the member, then design your concrete member using our Reinforced Concrete Design Software.

Also don’t forget to check out our Free Reinforced Concrete Design Calculator, a simplified version of the software! Or sign up today to get started!