Introduction to Wood Beam Design with CSA-O86-14

Wood beams are used for a large number of applications, from header beams over openings to structural beams to hold up floors or roofs. They offer a cheap, lightweight and easy to install solution for framing in Canada.

In Canada, the “CSA-O86: Engineering Design in Wood” standard outlines the means and methods to design wood structures in Canada. The standard covers everything from the design of CLT panels to the capacity of a nailed connection. For the average construction in Canada, the 6th chapter named “Sawn Lumber” is of particular interest.

Material Properties of Sawn Lumber

Sawn lumber, as the name suggests, is lumber that has been sawed from a larger tree. These members come in many dimensions, species and grades. In Canada, the quality control, identification and grading of lumber is overseen by the National Lumber Grades Authority (NGLA).

Moisture Content

One important property of wood, compared to other construction materials like steel or concrete, is the internal moisture content. Wood members expand and contract with changes in their moisture content, in processes termed hygroscopic swelling and hygroscopic shrinkage. The moisture content in the wood member depends on, among other things, the ambient relative humidity. The initial moisture content of a freshly cut tree is on average 75%. To stabilize dimensional variation and reduce risks of mold growth, manufacturers usually dry wood members to a moisture content of 19% before selling them. This condition is known as “S-DRY” and is often stamped on each individual dried member.

Categories

To determine wood member mechanical properties, the CSA-O86 standard divides all wood members into categories, species and grades. Categories refer to the dimensional and orientation component of the wood members. The categories are listed below:

- Structural light framing: Structural members that are less than 286mm deep.

- Light framing: Small wood members for light framing techniques.

- Beam and stringer: Structural members at least 114mm wide and a height at least 51mm more than the width.

- Post and timber: Structural members at least 114mm wide and a height less than 51mm more than the width.

Species Groups

While there are countless wood species in Canada, the CSA-O86 standard groups them into four distinct species groups:

- Douglas-Fir-Larch, which includes: Douglas-Fir and Western Larch

- Hem-Fir, which includes: Pacific coast hemlock and Amabilis fir

- Spruce-Pine-Fir, which includes: Spruce, Jack pine, Lodgepole pine, Balsam Fir and Alpine Fir

- Northern Species, which is a catch-all group for any other Canadian species graded by the NLGA

Grade

Finally, each individual member is either visually graded according to rules in the NLGA’s “Standard Grading Rules for Canadian Lumber” or machine graded according to a grading agency accredited for grading by mechanical means in Canada. Visual grading rules consider many characteristics of the wood member, including knot size, knot positioning, member twist, member pitch and member cup. Machine stress grading uses a specialized machine to determine the wood member’s flexural rigidity, which is correlated to the member’s bending resistance.

Design

With the wood member’s category, species group and grade, we can readily use the CSA-O86 standard’s tables to determine the wood member’s mechanical properties. Alongside the load combinations calculated in accordance to the National Building Code of Canada (NBCC), these properties can then be used for the full design of any wood beam member.

Advantages of Wood Over Other Materials

In Canada, wood is a cheap, accessible, eco-friendly and lightweight alternative to other construction materials. It does not require specialized labor and is easy to modify on site with simple tools. This is why some provinces (British-Colombia and Quebec) have recently allowed wood constructions up to 6 stories (the limit was previously 4 stories).

While engineering design of wood members is not always as straightforward as steel or concrete, having tools like the SkyCiv Wood Beam Capacity Calculator allows engineers to start using wood in their designs faster and with more confidence.

Using the SkyCiv CSA-O86-14 Wood Beam Capacity Calculator

To use the SkyCiv CSA-O86-14 Wood Beam Capacity Calculator, all of the beam characteristics and loading information must be entered into the input panel on the left-hand side of the screen.

Section and Material Properties

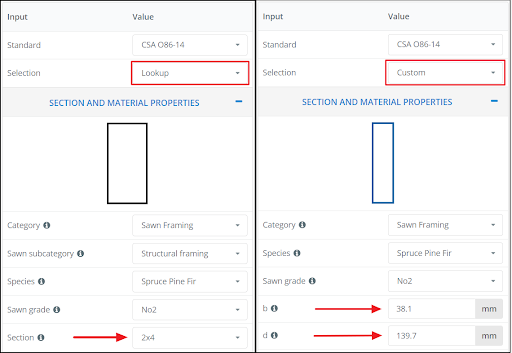

The selection drop-down menu allows for two ways of entering beam section information: Lookup and Custom. In the Lookup selection mode, imperial nominal wood sections can be selected in the Section drop-down menu. In the Custom selection mode, the beam width (b) and depth (d) can be entered manually. In this mode, the beam subcategory is automatically determined.

To determine material properties, the category, species and grade must then be entered. With these inputs, SkyCiv can fetch all of the relevant beam strengths in the appropriate database tables, such as the bending strength (fb), longitudinal shear strength (fv), parallel to grain compressive strength (fc), parallel to grain tension strength (ft) and modulus of elasticity (E).

Beam Properties

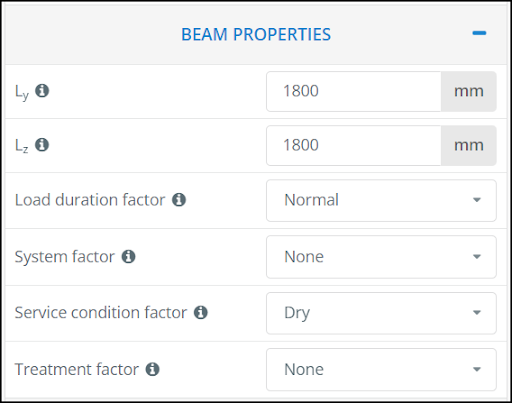

Next, the beam properties must be entered. The beam unsupported lengths (Ly and Lz) represent the longitudinal distance between supports in each direction. The unsupported lengths are used to evaluate the beam buckling resistance under compressive loads (in both directions), as well as the lateral stability resistance of the beam under strong axis (about the Z-axis) flexural loads.

The four following drop-down menus represent the CSA-O86-14 wood modifications factors. The load duration factor is determined automatically when load combinations are present (i.e., members are imported from S3D).

Factored Design Loads

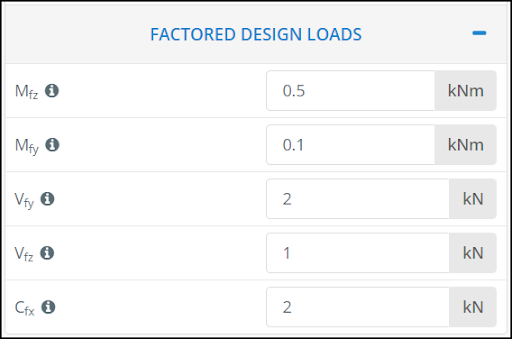

The last input subsection is for the factored design loads. The loads entered here must be the maximum values that act upon the beam, and must be factored according to the load combinations of the National Building Code of Canada 2015.

These can be obtained many ways:

- They can be calculated by hand using standard beam theory (see the following articles for more information: calculating shear force and calculating bending moments)

- They can be determined using beam calculation software, such as SkyCiv’s free beam calculator

- They can be automatically calculated in SkyCiv’s S3D finite element analysis software and imported.

Design Report and Output

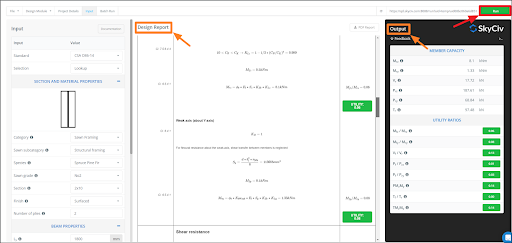

Once the inputs have been entered, run the analysis by pressing the green RUN button in the upper right-hand corner of the page (see the red box below). Once the analysis is complete, SkyCiv will return the design information in the typical two columns: the Design Report and the Output column (see orange boxes below).

The Design Report is a detailed report with step-by-step calculations. It can be downloaded using the PDF Report button on the upper right-hand corner of the report. The Output column is a summary of the beam resistance calculations, as well as the utility of each calculation. This allows users to verify everything at a glance.

Summary

SkyCiv’s Wood Beam Calculator makes validation of wood beams quick and simple. Try it free now and let us know what you think!

Other Canadian Design Tools

- NBCC 2015 Canadian Multi-roof Snow Drift Calculator

- CSA A23.3-14 Concrete Slab Resistance Design Software

- CSA 157-17 Aluminum Design

- CSA S16-14 I Beam Calculator

References

- Quebec Building Codes Recently Amended to Allow Wood in 6-Storey Structures, Weyerhaeuser, 25 July 2013, https://www.weyerhaeuser.com/blog/quebec-building-codes-recently-amended-to-allow-wood-in-6-storey-structures/.

- CSA-O86-14: Engineering Design in Wood. Canadian Standards Association, 2014.

- National Building Code of Canada. Ottawa, National Research Council of Canada, 2015.

- Standard grading rules for Canadian Lumber. National Lumber Grading Authority, 2022.

- Wood Design Manual, 2017. Canadian Wood Council, 2017.

Product Developer

BSc (Civil), MEng (Structural)