Table of Contents

- What is a Truss

- Truss Components and Terminology

- Benefits of a Truss

- Types of Trusses

- Free Truss Calculator

Definition of a Truss: What is a Truss?

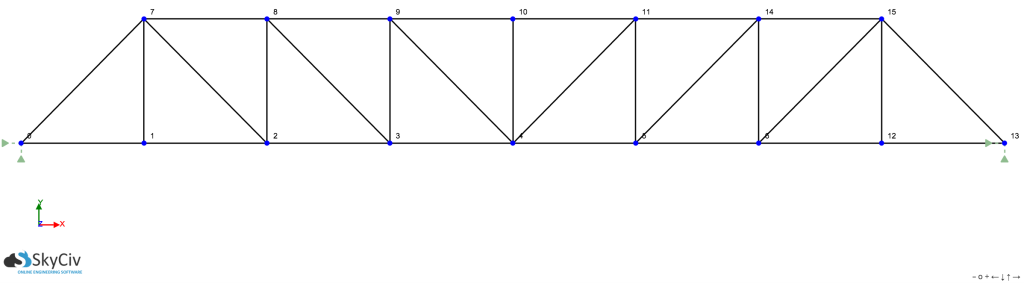

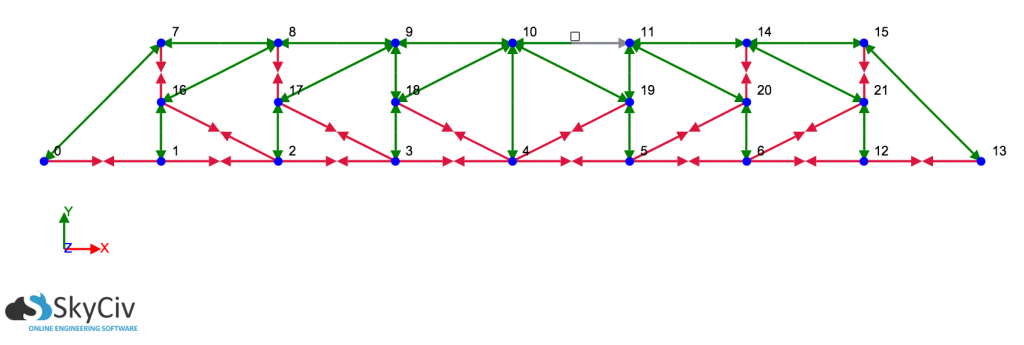

In structural engineering, a truss is an important type of structure characterised by a triangulated system of members. These members are structured and connected in a way such that they only incur axial force. The members of a truss are considered two-force members because the forces are only applied at either end of the member, resulting in either a compression or tension force. Trusses are commonly used in bridge designs due to their ability to efficiently span long distances. Here’s an example of a typical truss design:

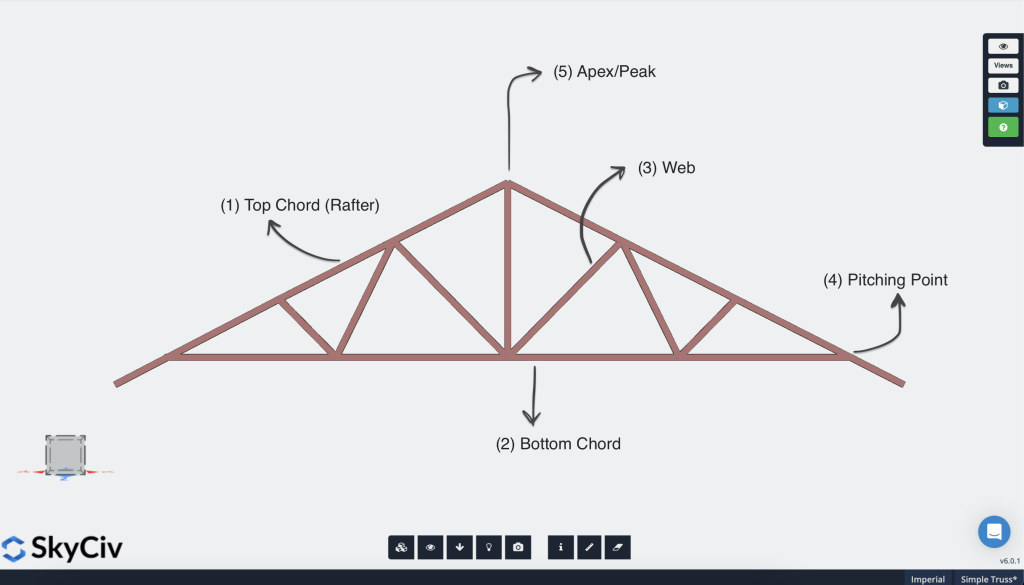

Truss Components and Terminology

Trusses typically follow a pretty general and common structure, made up of various components. Below is a list of the relevant parts of a truss:

- (1) Top Chord – the beam of a truss spanning the length of the truss

- (2) Bottom Chord – the bottom beam spanning the length of the truss

- (3) Web – these are the internal members of a truss

- (4) Pitching Point – the point where the sloping members (top chord) connects with the bottom chord

- (5) Apex/Peak – highest point of a truss

Benefits of a Truss

As we have explained the definition of a truss, let’s explore its benefits. When designed correctly, trusses are an efficient way to span long distances whilst minimizing the amount of material used. This is because the internal loads of the members are induced axially (in the direction of the member) in the form of compression or tension. This means less material can be used, and the system as a whole is more efficient, as the force is distributed among a number of members. Using a Truss Design Calculator can help engineers optimize these designs.

Source: Roof Truss Calculator

Types of Trusses

An appropriate truss type should be chosen for the design and construction to maximise the structure’s efficiency (which is often measured in the amount of material used or labour). In this article, we’ll look at the various types of truss bridges and how they can help your design. Trusses Calculator tools can assist in comparing different truss types.

Here’s the list of common types of trusses:

- Pratt truss

- Warren Truss

- K Truss

- Howe Truss

- Fink Truss

- Gambrel Truss

Pratt Truss

A Pratt Truss has been used over the past two centuries as an effective truss method. The vertical members are in compression, whilst the diagonal members are in tension. This simplifies and produces a more efficient design since the steel in the diagonal members (in tension) can be reduced. This has a few effects – it reduces the cost of the structure due to more efficient members, reduces the self-weight, and eases the constructability of the structure.

This type of truss is most appropriate for horizontal spans, where the force is predominantly in the vertical direction.

Pratt Trusses are most closely related to the Howe Truss, where the diagonal members are in the opposite direction (causing an inverse compression/tension behavior in the members).

It’s also important to note that in Pratt Truss Design, and most Truss design for that matter, is that the members have their end fixities set to pinned. This ensures that the force is all transferred in either compression or tension, with little (theoretically, none) transferred in the form of bending moment force.

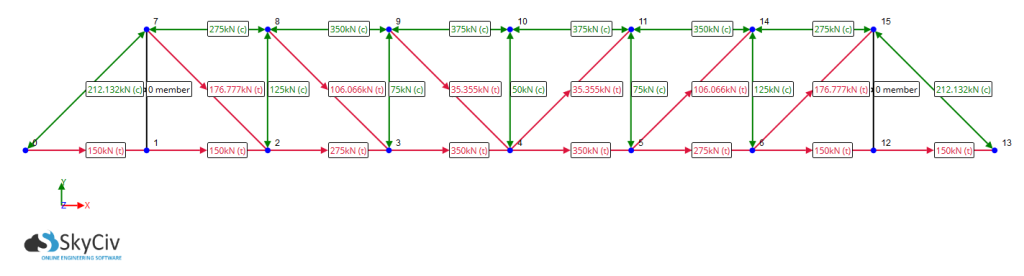

Below is an example of a Pratt Truss, constructed and analyzed using our SkyCiv Truss Design Calculator. Compressive members are shown as green and tension as red.

Advantages of Pratt Truss

- Aware of member’s behavior – diagonal members are in tension, vertical members in compression

- The above can be used to design a cost-effective structure

- Simple design

- Well accepted and used design

Disadvantages of Pratt Truss

- Not as advantageous if the load is not vertical

Best Used For:

- Where a cost-effective design is required

- Where a mix of loads is applied

- Where a simple structure is required

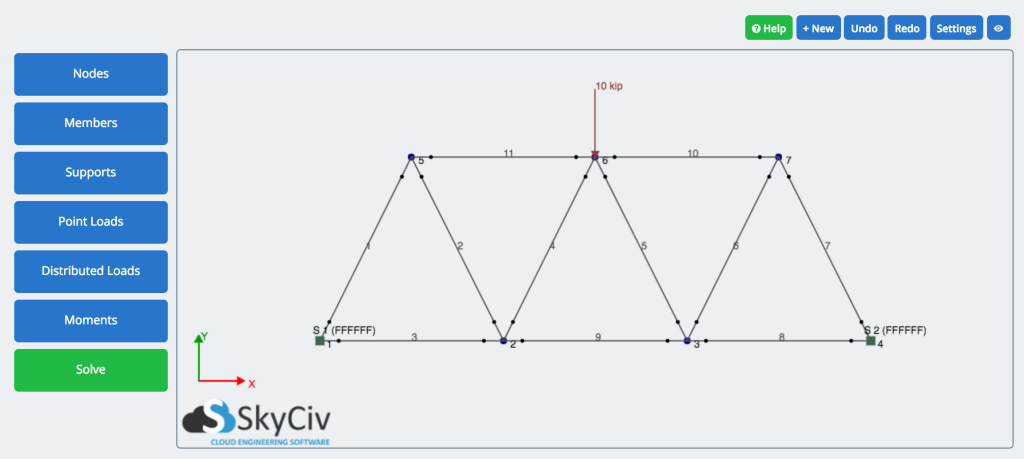

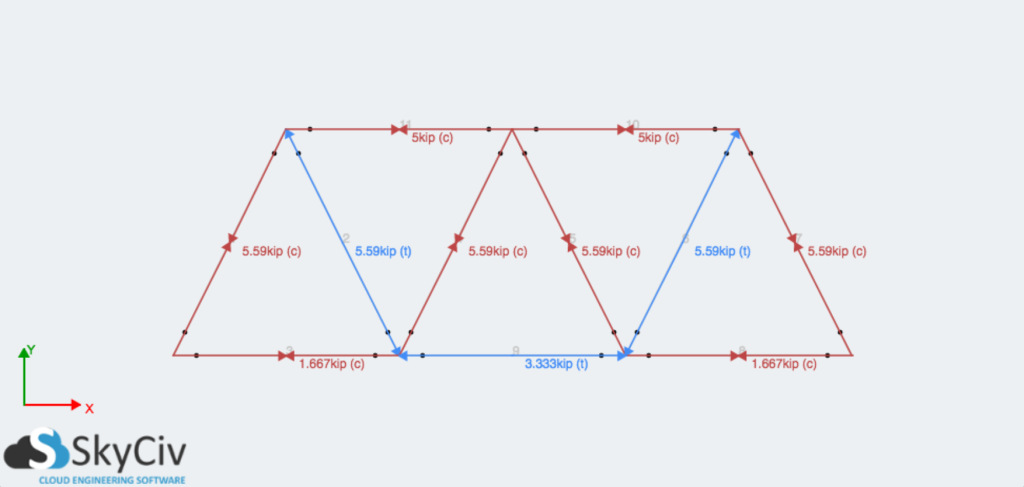

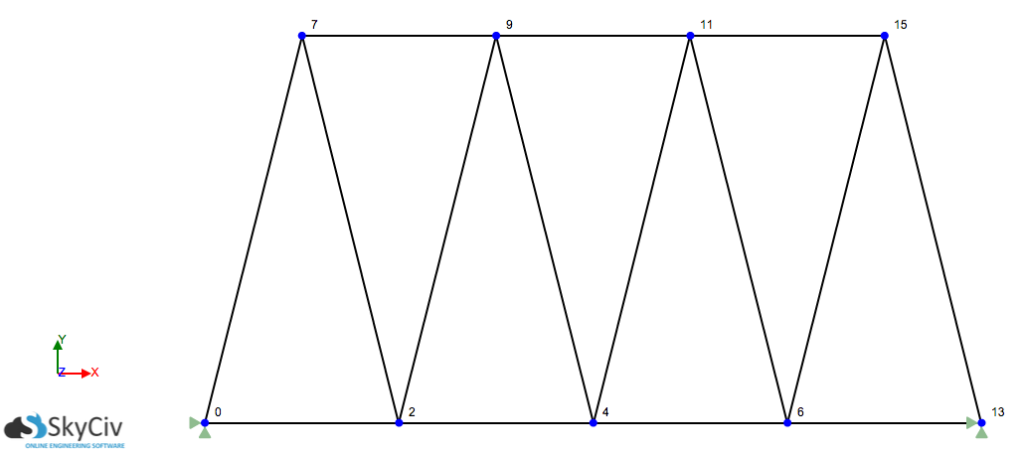

Warren Truss

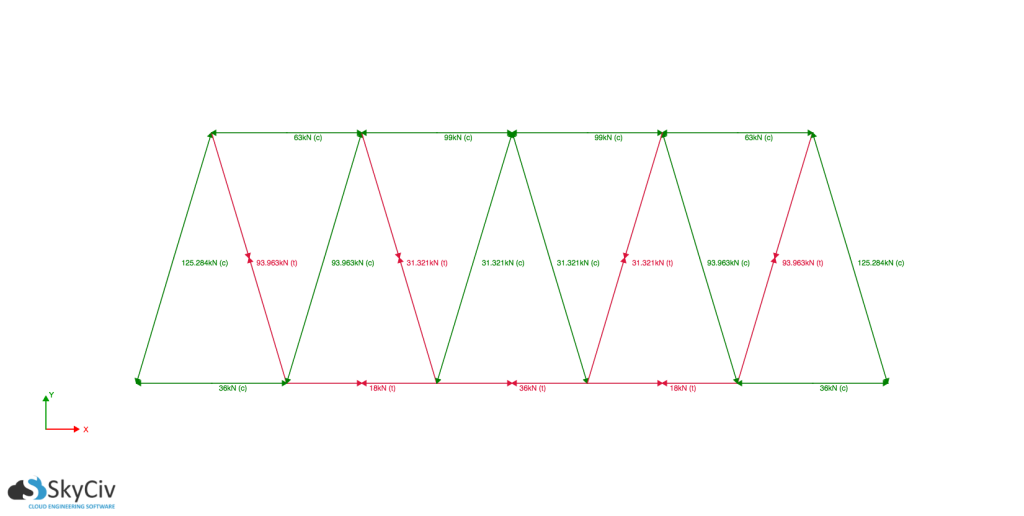

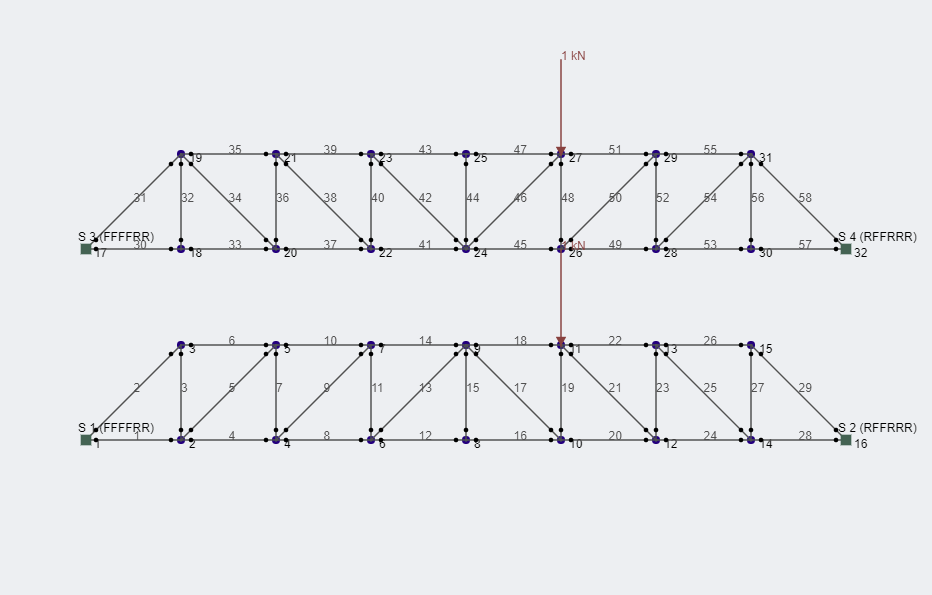

The Warren Truss is another very popular truss structure system and is easily identified by its construction from equilateral triangles. One of the main advantages of a Warren Truss is its ability to spread the load evenly across a number of different members; this is however generally for cases when the structure is undergoing a spanned load (a distributed load). Its main advantage is also the cause of its disadvantage – the truss structure will undergo concentrated force under a point load. Under these concentrated load scenarios, the structure is not as good at distributing the load evenly across its members. Therefore the Warren truss type is more advantageous for spanned loads, but not suitable where the load is concentrated at a single point or node.

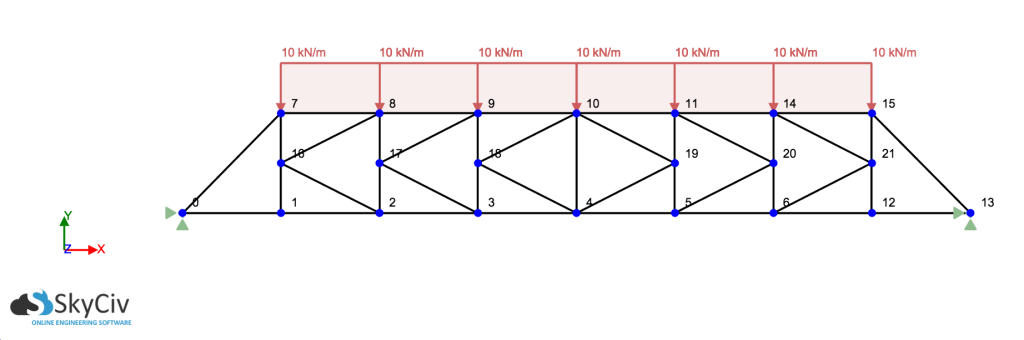

An example of a Warren Truss, and its axial forces under a distributed load is shown below. The structure was built and analyzed using SkyCiv Trusses Calculator. Compressive members are shown as green and tension as red.

Advantages of Warren Truss

- Spreads load fairly evenly between members

- Fairly simple design

Disadvantages of Warren Truss

- Poorer performance under concentrated loads

- Increased constructability due to additional members

Best Used For:

- Long span structures

- Where an evenly distributed load is to be supported

- Where a simple structure is required

K Truss

The K Truss is a slightly more complicated version of the Pratt Truss. Its main difference is that the vertical members have become shortened – improving its resistance against buckling. It does, however, have similar pros and cons to the Pratt Truss and although it is not widely used, it is a strong design. One of its main disadvantages is that the members don’t always behave as expected. A member may be in compression under one load scenario and in tension under another. This can mean the structure may not be able to be optimally designed – since

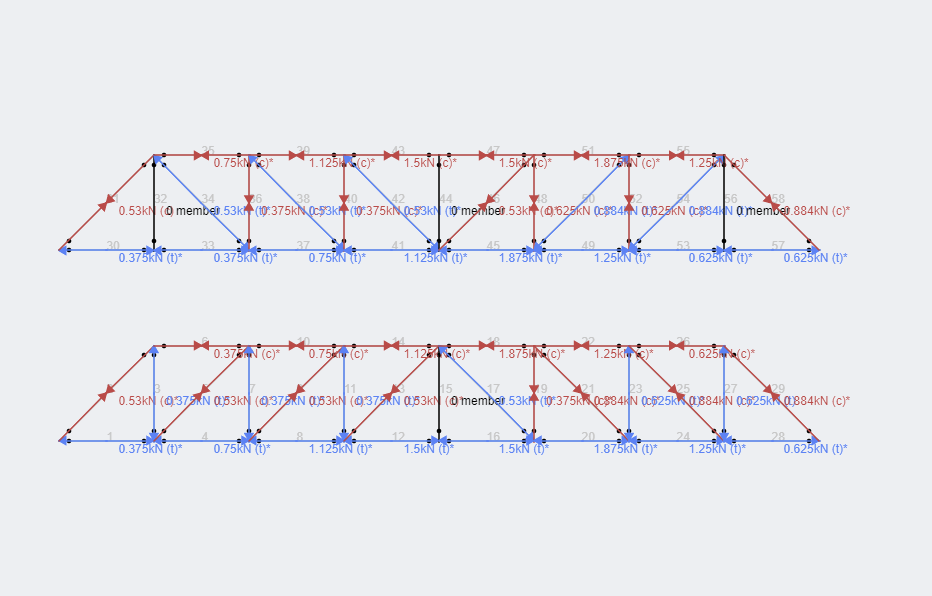

An example of a K-Truss setup and its reaction under an applied load is shown below. Compressive members are shown as green and tension as red.

Advantages of K Truss

- Reduced compression in vertical members

- Possible reduction in steel and cost if designed efficiently

Disadvantages of K Truss

- Slightly more complex

- Increased constructibility due to additional members

Howe Truss

Howe trusses are essentially the opposite of Pratt trusses in terms of geometry. In fact, looking at a Pratt truss upside-down will visualize a Howe truss of sorts. The entire structure is still relatively the same, but the diagonal braces are now occupying the opposite or the unoccupied joints. This switch in position of the diagonal members has a very important effect structurally.

A Pratt truss (above) and a Howe Truss (below)

Previously, we discussed how Pratt trusses have their vertical members in compression and diagonal members in tension upon the application of gravity loads at the joints of the top chord. For Howe trusses, the reverse becomes true as diagonal members are now in compression, while the vertical loads are in tension.

As they are similar in structure to Pratt trusses, their uses are generally the same. To maximize the efficiency of the truss, the truss can be loaded at the joints of the bottom chord. Roof trusses can be loaded with a ceiling load for example.

Another thing to note is that, depending on the geometry and loading, Pratt trusses can have more unloaded members than Howe trusses.

Fink Truss

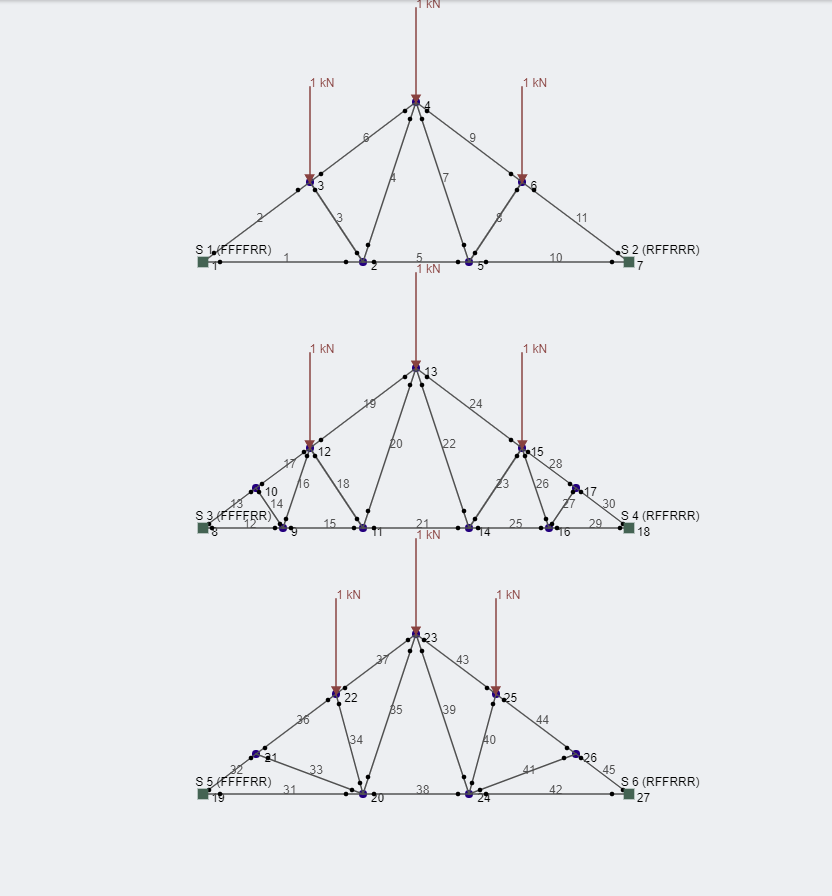

The Fink truss in its most basic form has web members that follow a V-pattern which can be repeated several times. As the top chords are sloping downward from the center, the V pattern becomes noticeably smaller. As Fink trusses rely more on diagonal members, they can be very efficient at transmitting loads to the support.

Derivatives of the Fink truss include the Double Fink and the Fan truss types. Double Fink trusses are essentially Fink trusses that repeat the pattern twice on either side. If the most basic Fink truss can be characterized by a double-V, then a double fink would look like a double-W. Fan trusses are essentially Fink trusses that have their web members ‘fan out’ from the joints at the bottom, usually with the addition of vertical members.

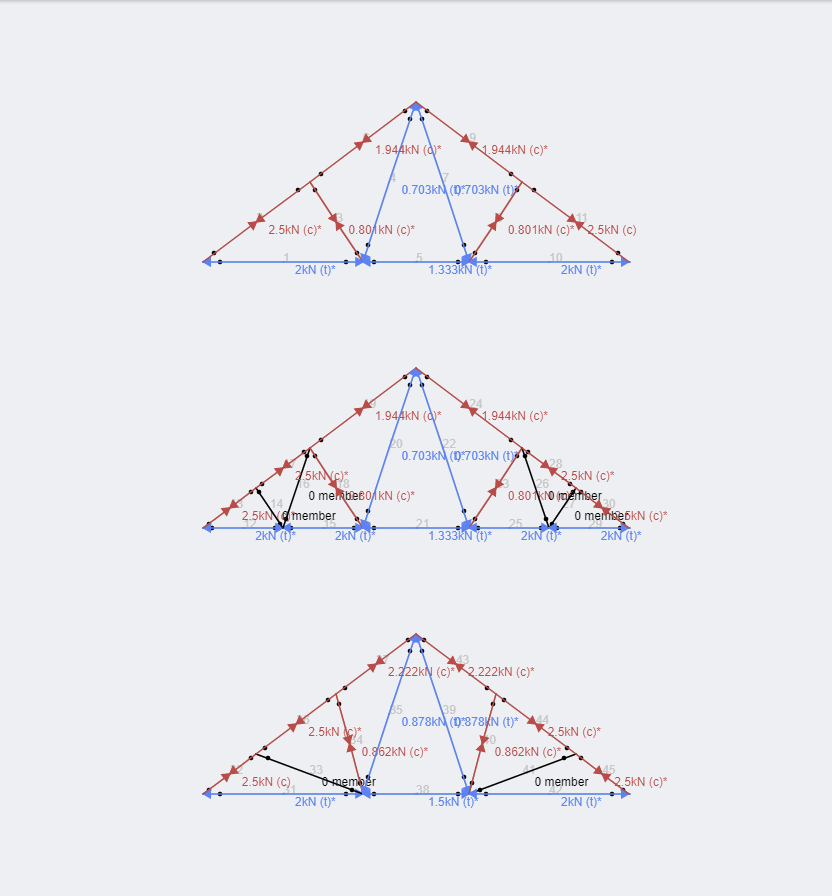

A Fink (top), a Double fink (middle), and a Fan Truss (bottom)

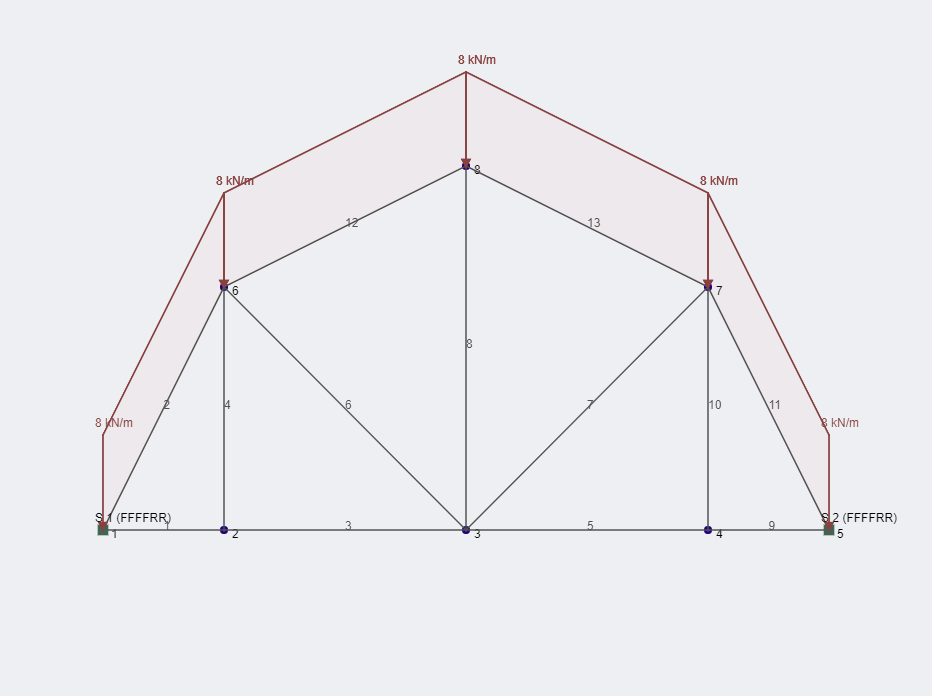

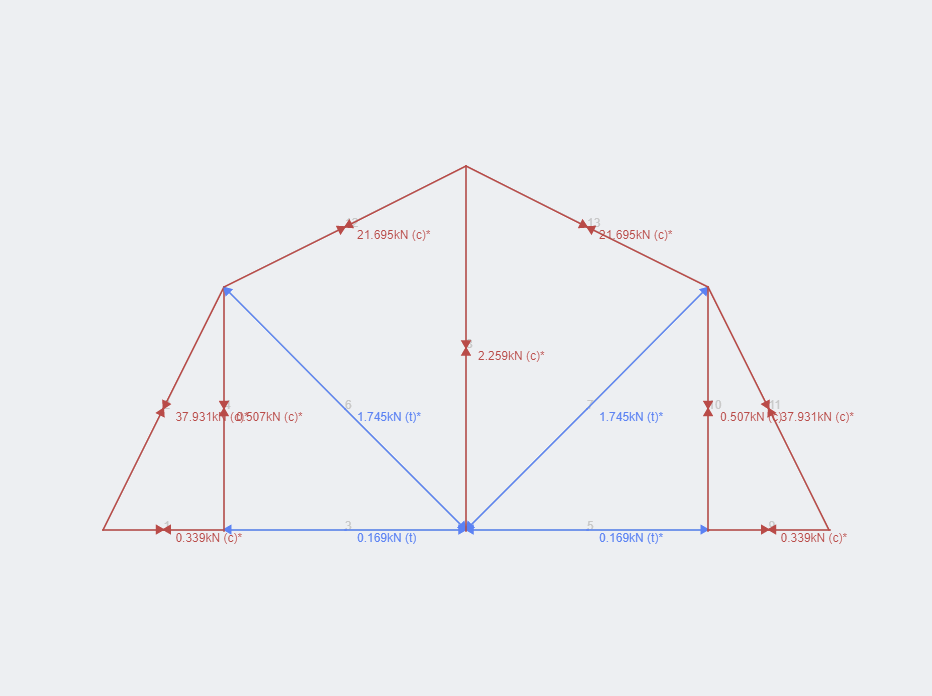

Gambrel Truss

On the exterior, a gambrel truss has two different slopes, where the slope gets steeper from the center. Due to its outward-protruding shape, gambrel trusses can effectively be fitted with a hollow center, which can be used as a storage area. As such, the upper section of a barn is usually shaped in a gambrel. In the case of a barn, as the members are usually constructed with wood, the structure acts more like a frame than a truss. Derivatives of the gambrel include the Mansard roof, which is also called a French roof, hence its popularity in France.

SkyCiv Truss Calculator

We hope you have found this tutorial useful. Visit our SkyCiv Trusses Calculator to use for yourself, and experiment with how trusses work.

Our Truss Calculator is a truss design tool that generates the axial forces, and reactions of completely customizable 2D truss structures or rafters. It has a wide range of applications including being used as a wood truss calculator, roof truss calculator, roof rafter calculator, scissor truss calculator, attic truss calculator, or for roof framing.

Sign up today to get started with SkyCiv software, or schedule a FREE DEMO to let us assist you with your specific engineering needs.