In some cases, non-prismatic or tapered sections are used in structural members to achieve a better performing structure. The idea behind non-prismatic members is to gradually provide less material and therefore less capacity in the portions of the member where the internal forces are smaller, and more material in the portions where the internal forces are larger. In other words, tapered sections try to follow the internal forces/stresses distribution along the member.

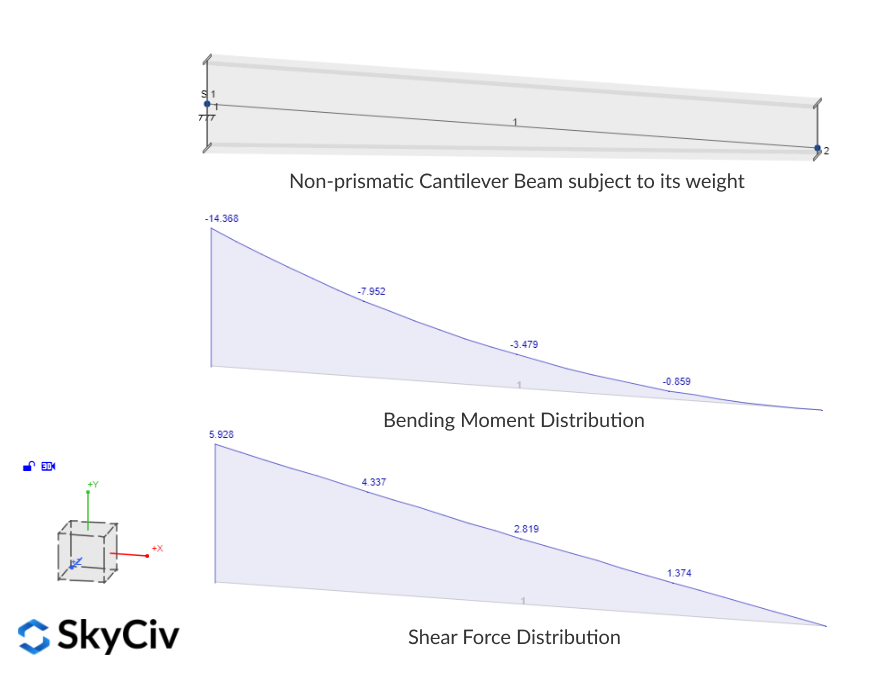

For example, in a cantilever beam subject to its own weight, the bending moment and the shear force take their maximum values at the fixed end and are zero at the free end, following a quadratic and linear distribution respectively. In that case, the fixed end of the beam demands the maximum capacity while the free end does not have any demand, for that reason, a tapered section can help to save material and efficiently use the available capacity.

There is another article that explains in detail how to model non-prismatic or tapered sections and haunches and how the linear section variation is idealized with shorter prismatic members at the analysis stage. In this article, we will focus on how the SkyCiv Member design module deals with non-prismatic sections when performing the design checks. At the moment, there are a few fully supported non-prismatic sections in the software:

- Cold-formed Non-prismatic Boxes (rectangular hollow sections composed by two lipped channels) as per AS/NZS 4600:2018

- Welded-plates Non-prismatic I-Beam as per AS 4100:2020 and NZS 3404:1997

In those codes, there are two different types of checks that need to be fulfilled across different limit states: section checks and member or segment checks. Before diving into each group of checks, let’s quickly review the available information about the sections that comes from the analysis stage.

Available section properties

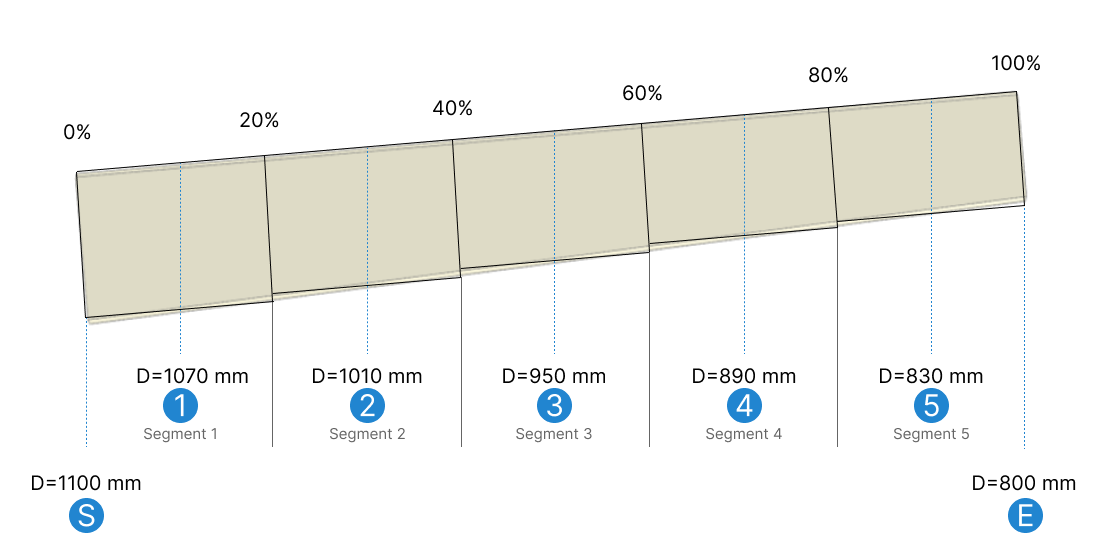

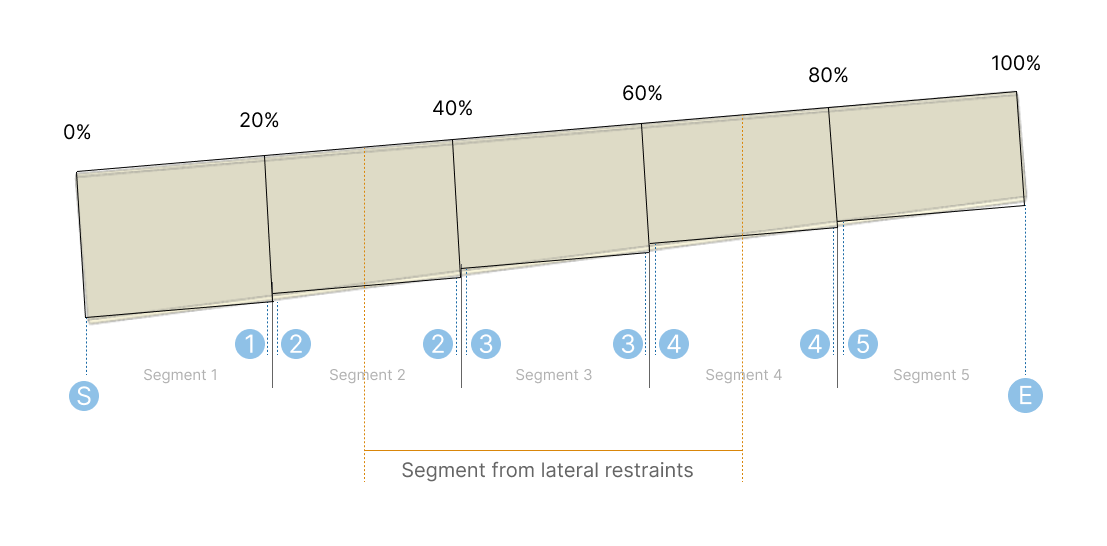

Assuming the tapered section was set up with “average” prismatic member sizes and 5 prismatic segments, there will be 7 stations (shown as blue dotted lines in the below diagram) with calculated/known section properties, corresponding to the sections that a linearly-variating non-prismatic member would have at the middle of each prismatic segment. This is shown in the picture below labeled as S (start shape), 1, 2, 3, 4, 5, and E (end shape). For the example, let’s variate the section depth from 1010 mm to 800 mm.

Section checks

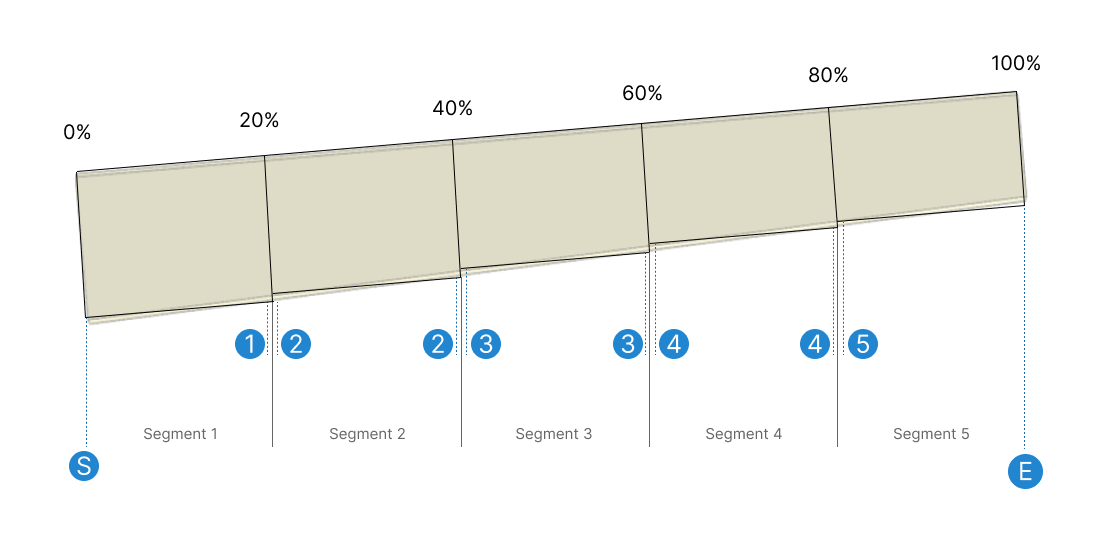

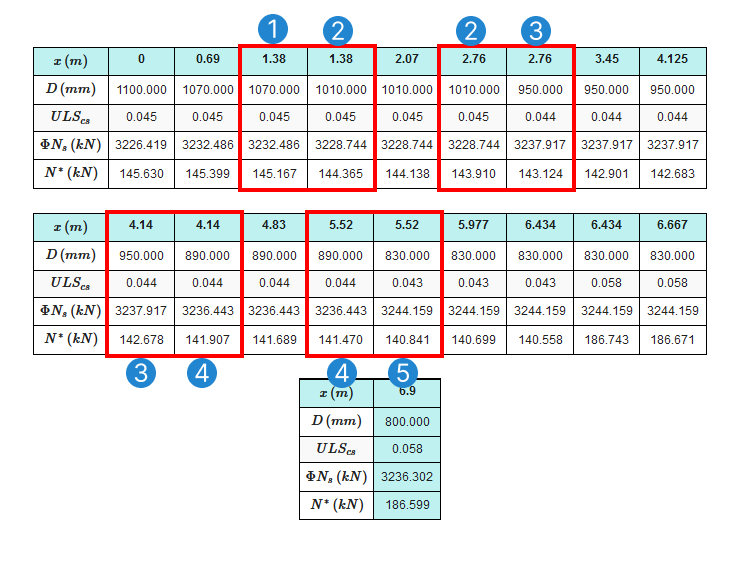

Sections checks are performed station by station using the capacity of the section at the given station and the internal forces that act individually or combined exactly at that position along the member. Each station will use the section properties of the prismatic segment that station belongs to. Right at the prismatic segments’ variation, there will be two stations at the same location with a different section, one station belonging to the segment on the left of the variation and the other to the right of the variation:

This is why in the design report there are repeated stations with two different capacity values, each station uses a different section and can therefore produce different results. So the final checking stations comprise of (a) the evaluation points from the analysis results and (b) the total number of stations plus using the above logic:

Member checks

For the member or segment checks, individual segments are defined by the lateral restraints specified by the user. Those restraints come from other elements in contact with the design member, such as purlins and fly-braces that help prevent buckling in the member. For member checks, the internal forces used are the maximum results present within the segment, no matter if they occur at different positions along the member. The section used for the capacity is chosen from the available sections using one of the following criteria:

- Critical section: Section of the station with the highest utility ratio from the section check.

- Minimum section: Section with the lowest area/capacity.

- Mid-length section: Section closest to the geometrical mid-span of the segment.

As an example, let’s take a segment that, due to the assigned lateral restraints, runs from the middle of Segment 2 (30%), to the middle of Segment 4 (70%) as shown in the image below.

Assuming the critical station for that segment is at the start of the segment (the middle of the second global prismatic segment – 30% of the whole member), the section used for the capacity in the member check will be:

- Critical section: Section 2

- Minimum section: Section 4

- Mid-length section: Section 3, which is the closest available section to the 50% of the lateral restraints segment (middle of the third global prismatic segment)