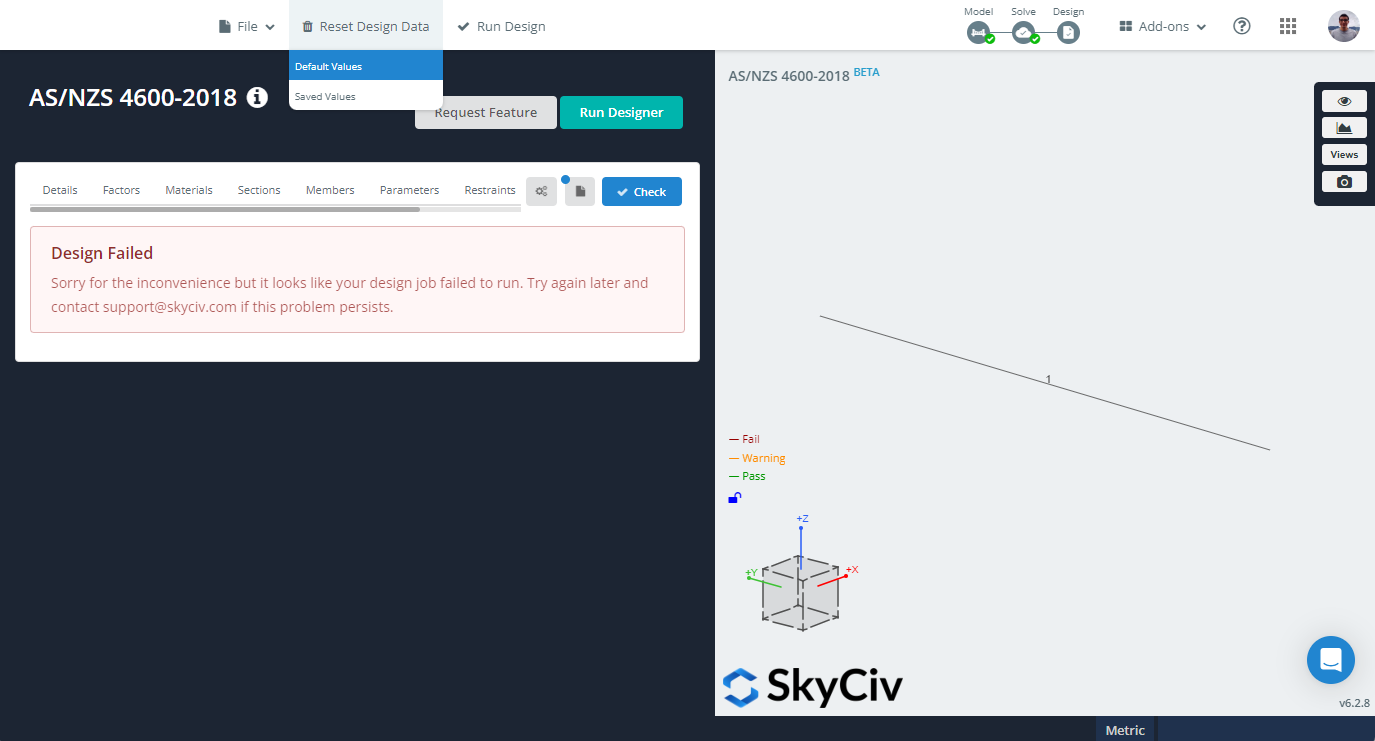

Resetting Design Data to Default Values

In some cases, after modifying design data—such as adjusting effective lengths, customizing member restraints, or updating parameters to better reflect real-world conditions—the data might become corrupted and unusable. When this happens, the design check fails, and you might receive a message like, “Sorry for the inconvenience, but it looks like your design job failed to run. Try again later and contact [email protected] if this problem persists,” or you may be prompted to “try resetting the design data to its default values.”

To reset the design data to its default values and potentially resolve these issues, follow these steps:

- On the top bar, locate the Reset Design Data button, which is next to the File button.

- Hover your cursor over the Reset Design Data button.

- In the menu that appears, click on the Default Values option.

This action will delete any manually entered or modified design data and replace it with the default values. After resetting, try running the design check again.

Ensuring proper load combinations

Every design code divides its major limit states into two groups: ultimate (strength, stability) and serviceability. Each group has its own load combinations, and each limit state is evaluated under the action of its corresponding load combination. Checking ultimate limit states with serviceability load combinations can lead to inaccurate results because the strength reduction factors and safety factors are designed to work with the appropriate load amplification/reduction factors. Similarly, checking serviceability limit states using ultimate load combinations can also produce incorrect results, as the deflection limits and stiffness reduction factors are intended to work with the correct load factors.

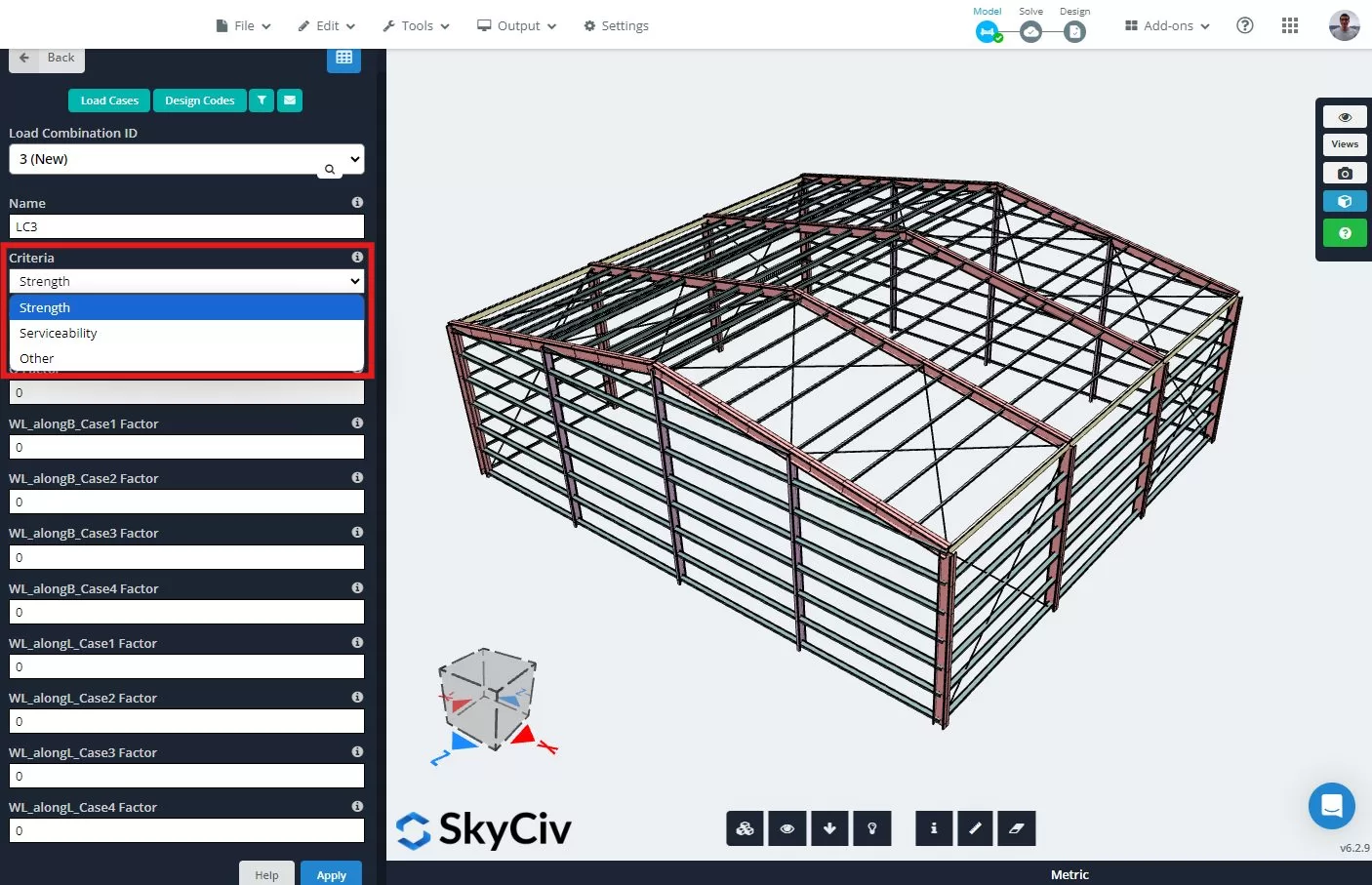

In SkyCiv S3D, you can set the criteria for each load combination to “Strength” or “Serviceability.” Ensure that each load combination is correctly classified under the appropriate criteria. We offer an extensive catalog of load combinations from multiple design codes, with each combination already classified correctly. For more information, please refer to our documentation on importing load combinations from design codes. To manually set the criteria for each load combination, go to the Load Combos section on the left panel and select the appropriate option.

For the software to check all available ultimate and serviceability limit states, you must have at least one load combination set to “Strength” and another set to “Serviceability.” You can use the datasheet view of the load combinations to quickly check and adjust the criteria for all the load combinations.