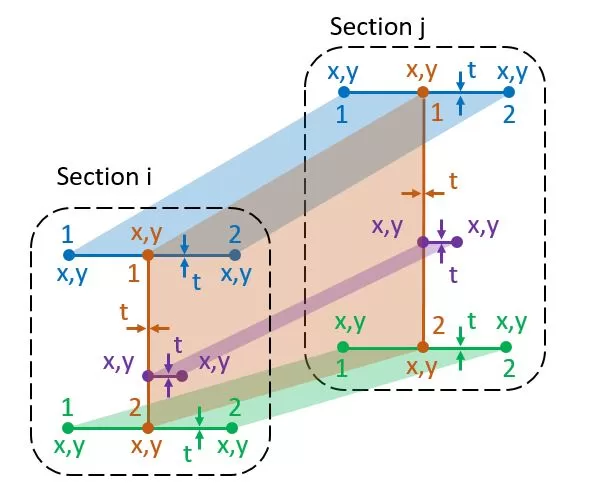

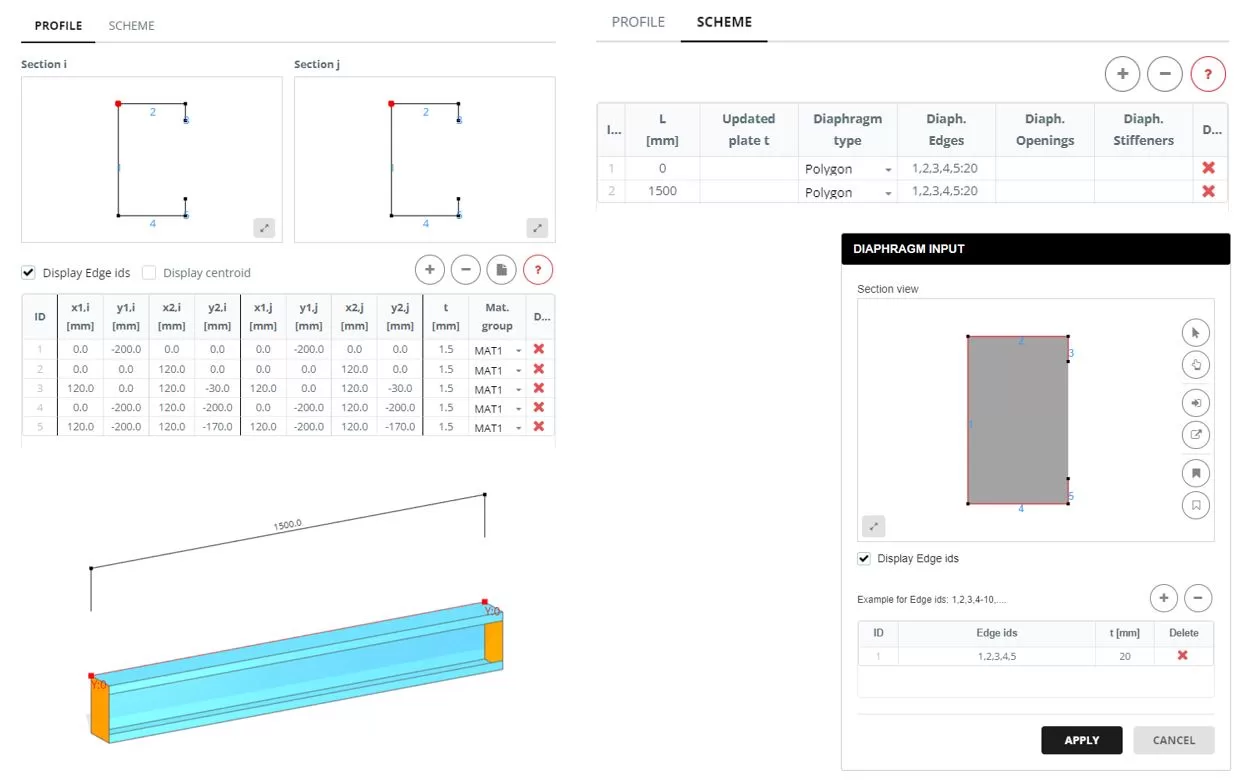

Each member has a starting section i and an ending section j. A section consists of lines defined by two nodes, x,y in the section’s plane. Each line possesses a distinct thickness t and belongs to a specific material group. The reference point for x,y coordinates can be chosen arbitrarily in space for each section. The number of lines in each section must be consistent. Data for the table can either be entered manually or imported from an Excel sheet. Additionally, section shapes can be imported from a DXF file stored on the user’s PC.

Update t: The common thickness can be changed for selected group of lines

Update Mat.: The common material group can be changed for selected group of lines

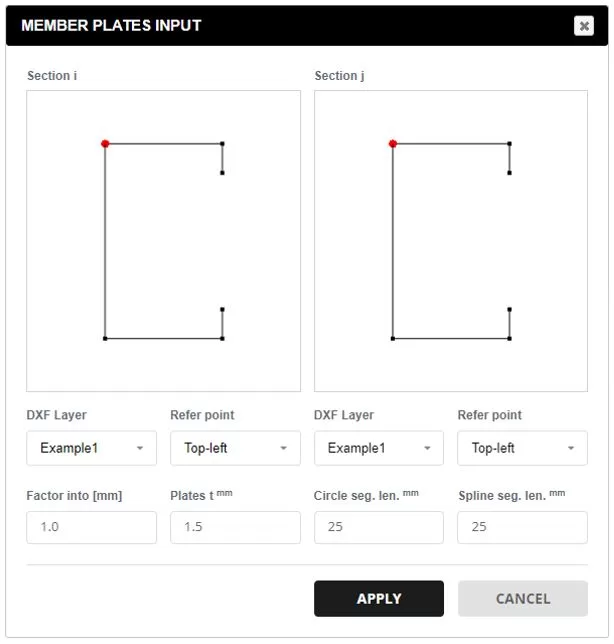

Data from DXF.: Select a DXF file from your PC. Choose the desired layer for section items. The reference point determines the origin for the x,y coordinates. Use the factor to scale section coordinates to millimeters. A default thickness will be applied to all lines, which can be modified later. Supported DXF entities include: Lines, Polylines, Arcs, and Splines. For Arcs and Splines, segment division is specified to match the preferred mesh size.

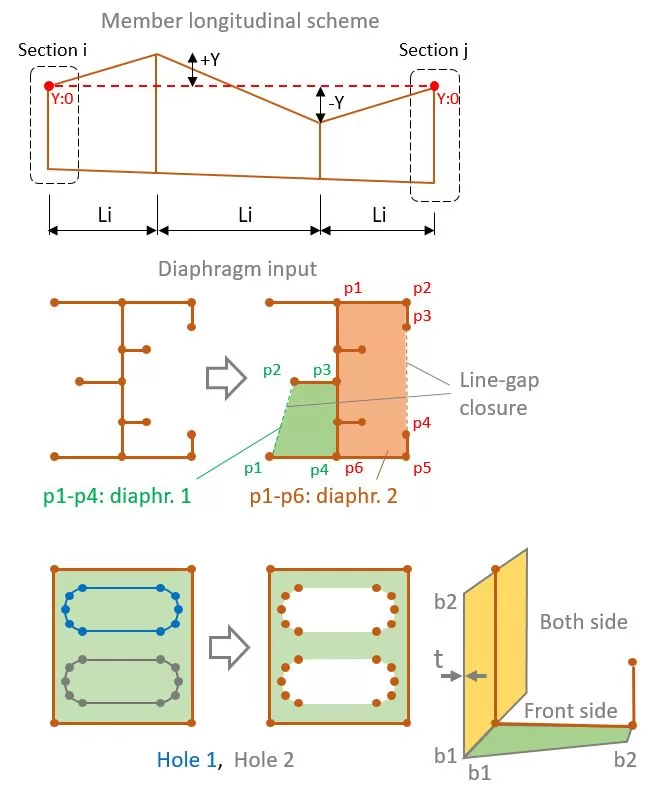

The entire member can be represented either by a single length L or by a series of segments Li. Regardless of the number of segments, the starting and ending section lines will have the same coordinates as defined in the PROFILE tab. Each section can also have different Y position.

For each segment where L is not equal to 0, the thickness for a group of plates can be updated in the ‘Updated plate t column’. Enter 0 to hide the plate and a value greater than 0 to modify the thickness (t).

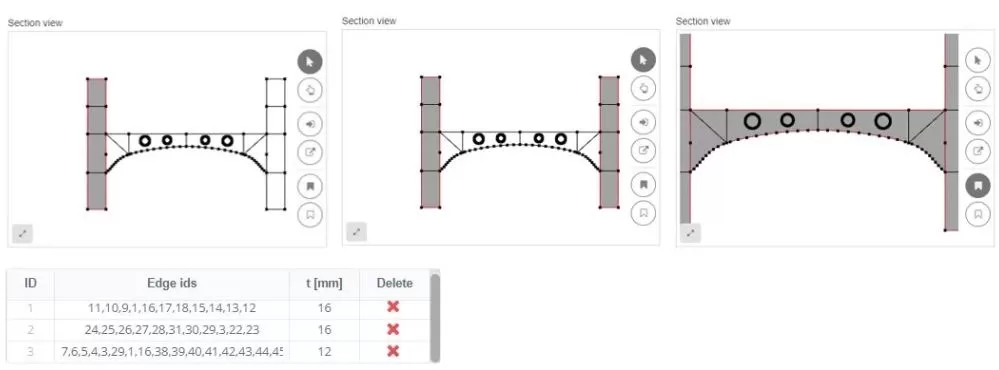

For segment sections, a diaphragm can be added if the ‘Polygon’ type is chosen. To specify one or more diaphragms, select the lines composing the shape. Only one line-gap closure is permitted to form the shape.

Holes can also be incorporated within the diaphragm. To do this, define the hole shapes by selecting the corresponding lines that encompass the holes.

If a diaphragm is specified, then flanges or stiffeners can also be defined by selecting their associated lines. Each flange or stiffener has a starting and ending width (b1,b2), thickness t, and material group.

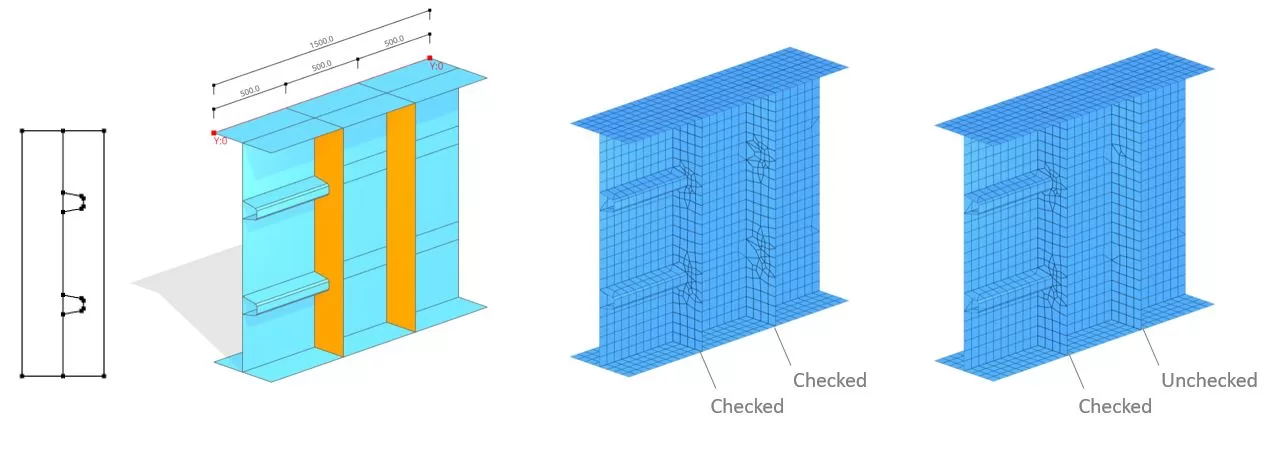

Example

When arranging edges within a diaphragm, they can be factored into the meshing pattern. For instance, a situation may arise where a longitudinal stiffener is connected to a vertical one. In such scenarios, the ‘inner edges’ option should be activated. However, if the vertical stiffener is not attached to anything, this option can be deactivated.