What is Reinforced Concrete?

Reinforced Concrete is the common term given to a concrete member (or slab) that contains steel reinforcement (usually in the form of steel bars) to increase the strength of the structure. The material that results from the combination of concrete and reinforcing bars is called Reinforced Concrete (RC). During construction, the reinforcement steel is placed in the formwork first, either in the form of a prefabricated steel cage or steel rebars that are fastened together and wired in-situ. Then concrete is poured into the formwork and vibrated using adequate devices so as to guarantee a high level of collaboration between the two materials.

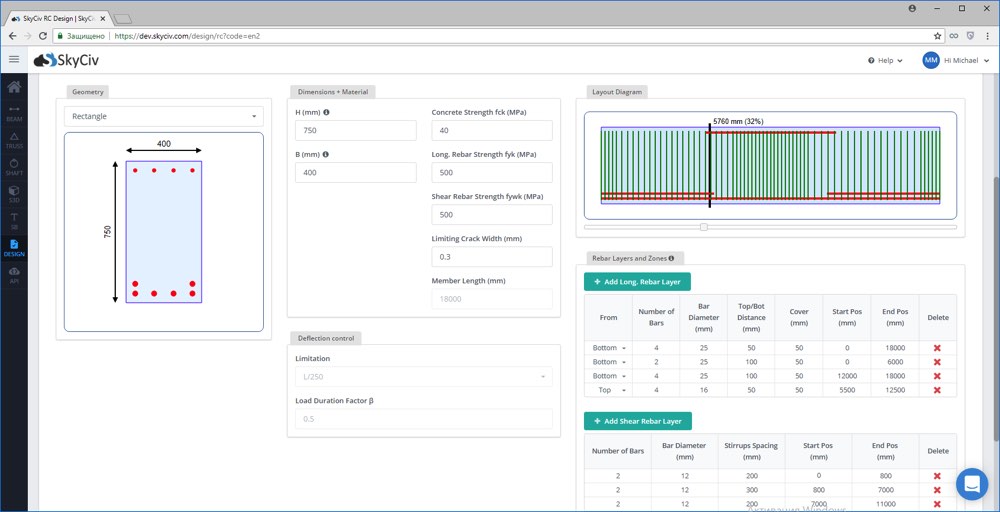

Our Concrete Structure Design Software supports reinforced concrete design with beams, slabs, and columns. Check it out!

Figure 1: Rectangular concrete beam, with steel rebar, is an example of a reinforced concrete member

Why is Reinforcement in Concrete Important?

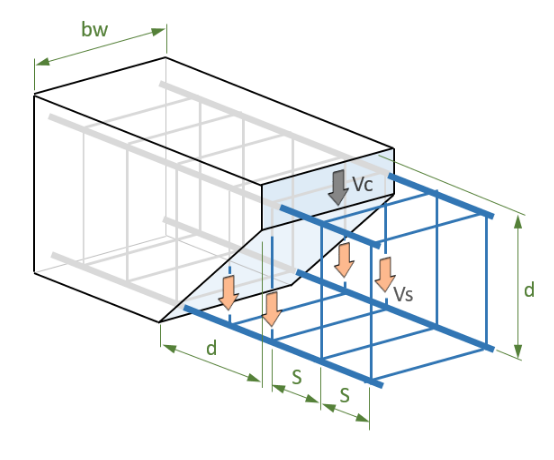

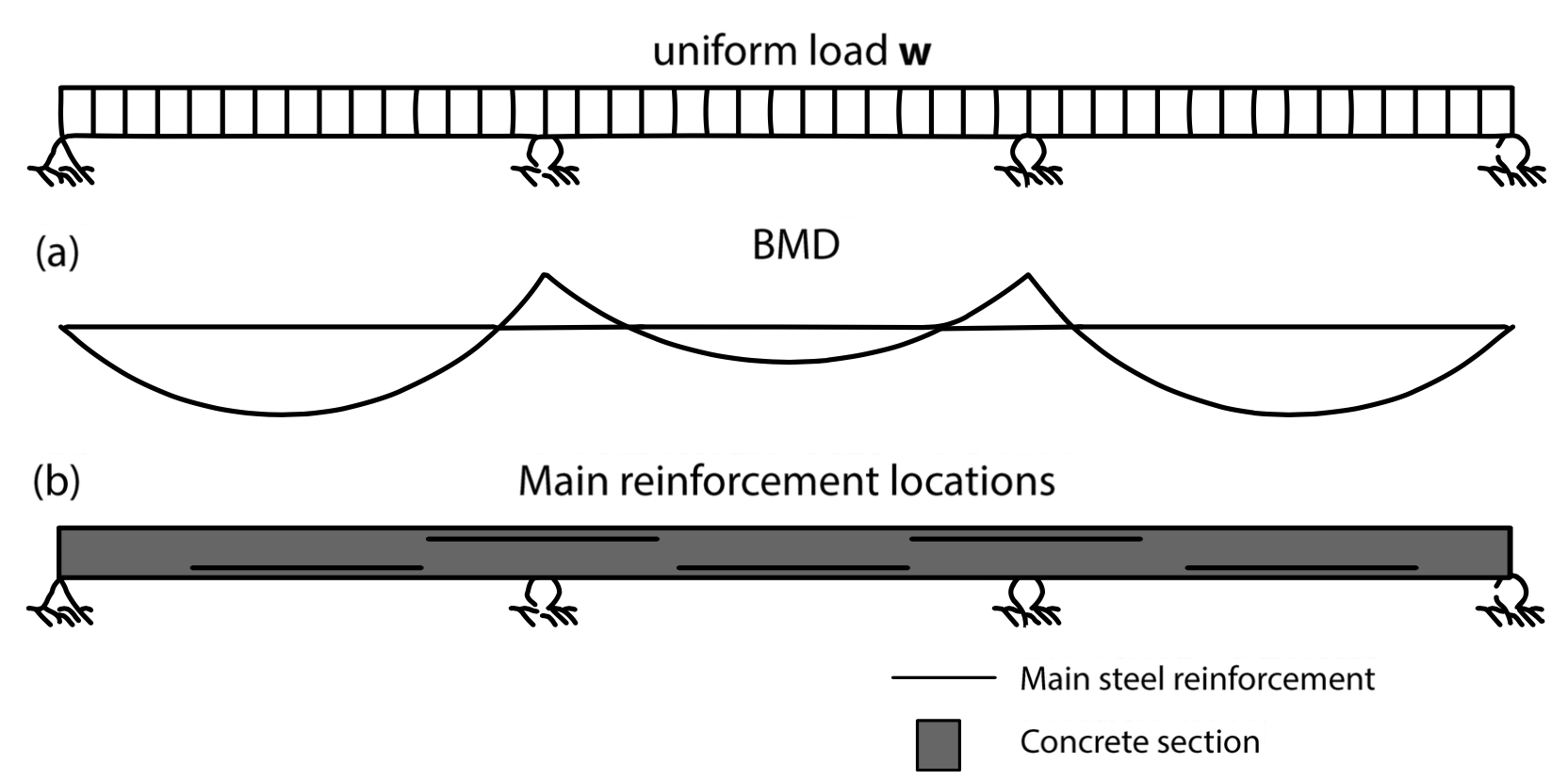

One of the main disadvantages of concrete is its very low tensile strength that is practically exceeded at low levels of load. This results in cracking of the concrete surfaces that in turn leads to aesthetical problems (large deflection of beams or slabs) for the serviceability limit state as well as structural integrity problems at the ultimate limit state. On the other hand, reinforcing steel has rather high tensile strength and a symmetrical material constitutive law under tension and compression. However, rebar alone that is subjected to compression fails prematurely due to buckling. For these reasons, the use of reinforcement in an RC section leads to effective structural behavior as reinforcing steelworks effectively under tension and concrete works effectively under compression and confines the compression reinforcement. Figure 1 shows the Bending Moment Diagram of a continuous beam under vertical loads as well as the locations where reinforcing steel should be placed.

Figure 2: 3-span continuous beam under uniform loading: (a) Bending Moment Diagram and (b) Main reinforcement locations.

Where is Reinforced Concrete Used?

Nowadays, Reinforced Concrete is commonly used in modern construction, mainly for buildings and bridges. Such projects may include a great variety of members, such as:

- Plate-type members: horizontal plates (slabs, bridge deck slabs, and raft foundation slabs) or vertical (e.g. shear walls and core walls around staircases or elevators)

- Line-type members: such as beams, columns, or piles.

Under vertical loading plate-type members offer stiffness and strength in more than one direction within the member’s plan, while line-type members confer strength and stiffness primarily in one direction.

What are some examples (cross-sections) of RC?

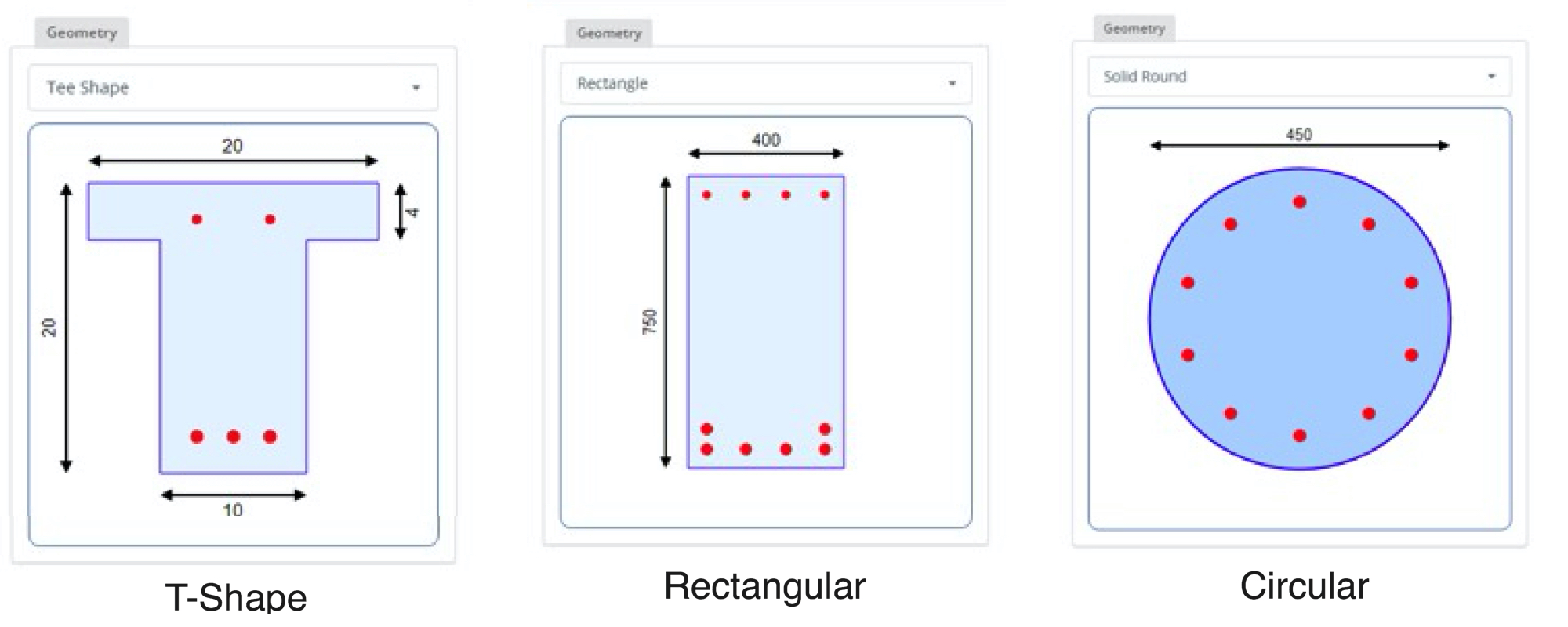

The cross-sections of vertical linear members such as columns and piers have rather simple geometry (most often square, rectangular, or circular – see Figure 2) dictated by the fact that these members must offer equal or similar resistance in all horizontal directions. Moreover, such geometric configurations lead to reduced costs related to formwork. The cross-sections of beams used in building projects have a common rectangular shape, while bridge girder cross-sections have mainly I-shape so as to reduce weight and accommodate the placement of post-tensioning tendons.

Figure 3: Typical reinforced concrete sections

SkyCiv Reinforced Concrete Design Software

SkyCiv offers an easy-to-use reinforced concrete design software to help analyze and design reinforced concrete members.

Using SkyCiv Beam Software, you can analyze the loads on the member, then design your concrete member using our Reinforced Concrete Design Software. SkyCiv Reinforced Concrete Design supports concrete beam design and column design for a variety of building codes. So check it out now to get started!