The double angle connection is one of the five basic shear connection types presented in part 10 of the 15th Edition AISC Manual. This connection type is a fabricator-favorite especially at beam to column web connections.

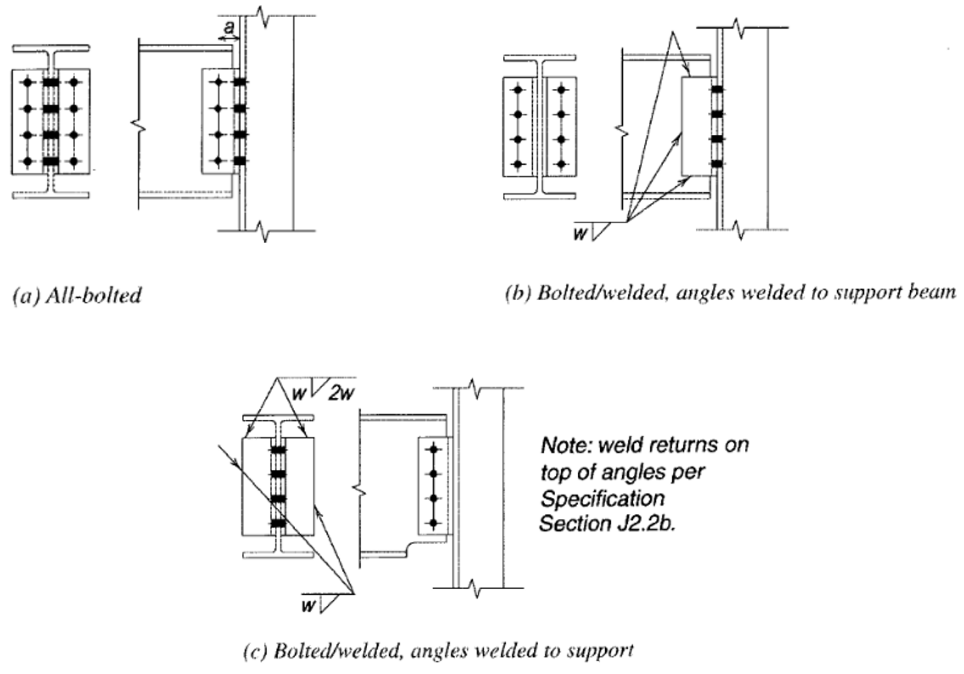

A double angle shear connection consists of two angles, one on each side of the beam web. This can be either bolted or welded to the beam web or the support. Typically, on a beam to column web connection, the angles are welded to the beam and bolted to the support. This combination requires a somewhat smaller leg angle which is ideal if the allowable space inside the column web is limited since you don’t need a larger clearance for bolt fitting as compared to an all-bolted connection. An all-bolted double angle connection is usually preferred at beam to girder configuration especially if a single angle connection won’t work since it will have double the capacity.

The double angle shear connection is favored for its ease of installation. It can be put together in the field using basic tools and equipment and doesn’t require special fabrication. This makes it a popular option in construction projects.

However, designing the double angle shear connection requires attention to several factors. AISC provides detailed guidelines that take into account the load capacity, bolt spacing, edge distances, shear deformation, and bending deformation to determine the allowable loads for different bolt and angle sizes and grades.

Spacing between bolts is critical to the connection’s performance, as too few bolts can lead to overstressed bolts and angles, while too many bolts can be unnecessarily costly and difficult to install. Additionally, distances between the angle and beam flange edge, as well as distances between adjacent bolts, must be chosen to prevent material overstress and ensure adequate load transfer.

The double angle shear connection can experience shear and bending deformation, which can result in the rotation of the angles and loss of load capacity or excessive stress on the bolts and angles. AISC guidelines provide formulas to calculate and limit the effects of these deformations.

AISC also provides guidelines for the use of the double angle shear connection in different beam types and loading conditions. For example, the guidelines for connections in simply supported beams differ from those for continuous beams.

The double angle shear connection is a valuable connection type in the construction industry. However, careful consideration of the factors mentioned above is necessary to ensure its safe and effective performance. Following AISC’s guidelines when designing and installing this connection type is essential to optimize its performance.

Now onto using the software.

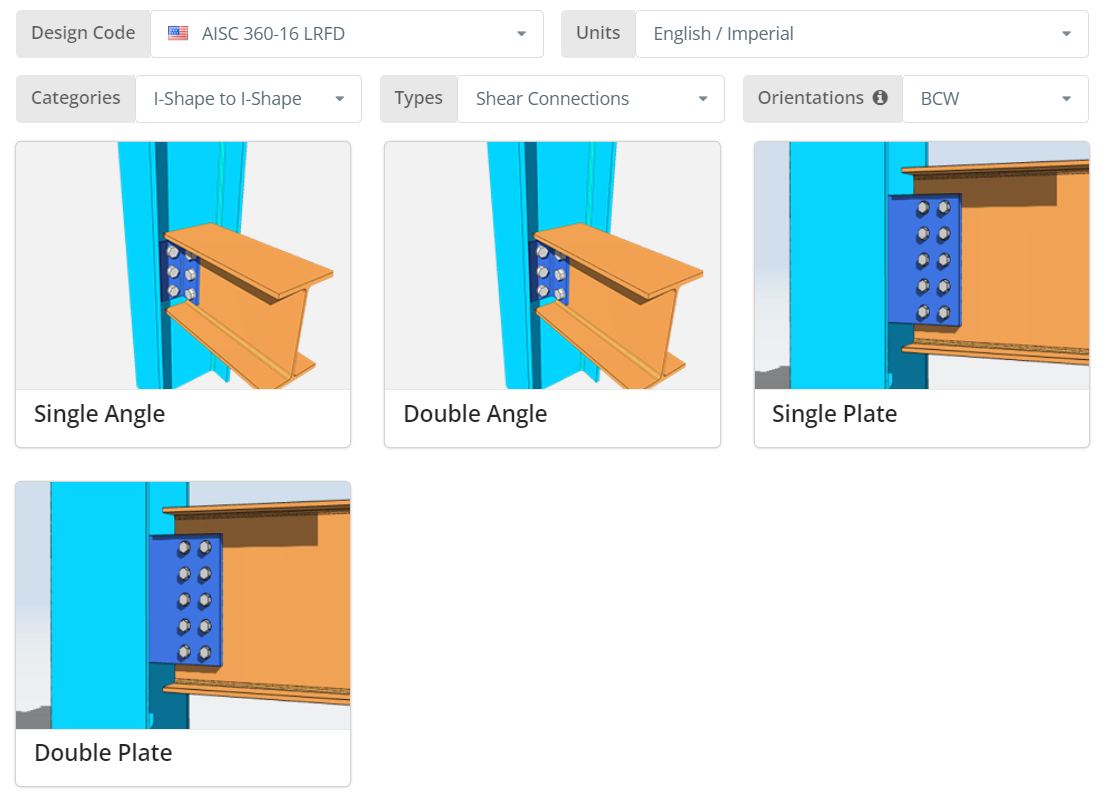

The Design Code can be AISC 360-16 ASD or LRFD. Units can be English/Imperial or SI/Metric. Orientation can either be BCF, BCW or BBW. Hover over the tooltip for more info. Now click the “Double Angle” tile.

Project Tab

Here you can specify the details of the project you are currently working.

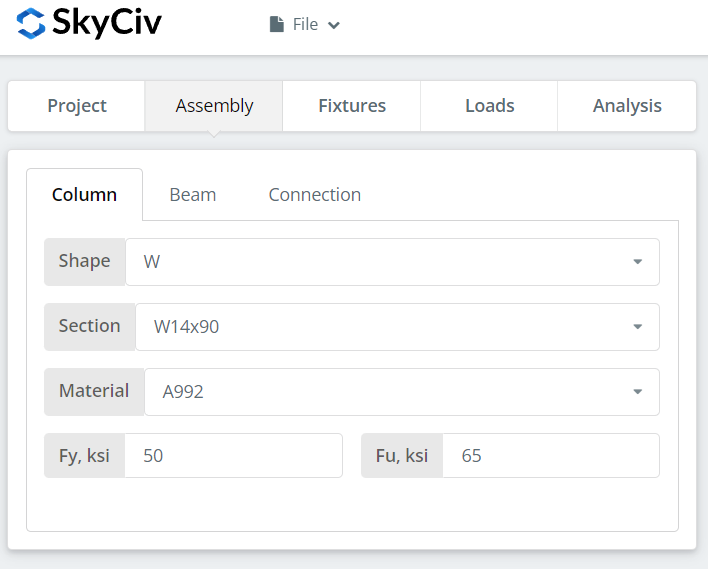

Assembly Tab

There are three tabs under Assembly. This is where you specify the Column, Beam, and Connection (Double Angle) properties.

Column Tab

Here you can specify the section/shape of the column and its material grade. You can either choose A992 or A36 material. But if you are using a different material, you can choose Custom and manually input the Fy and Fu values.

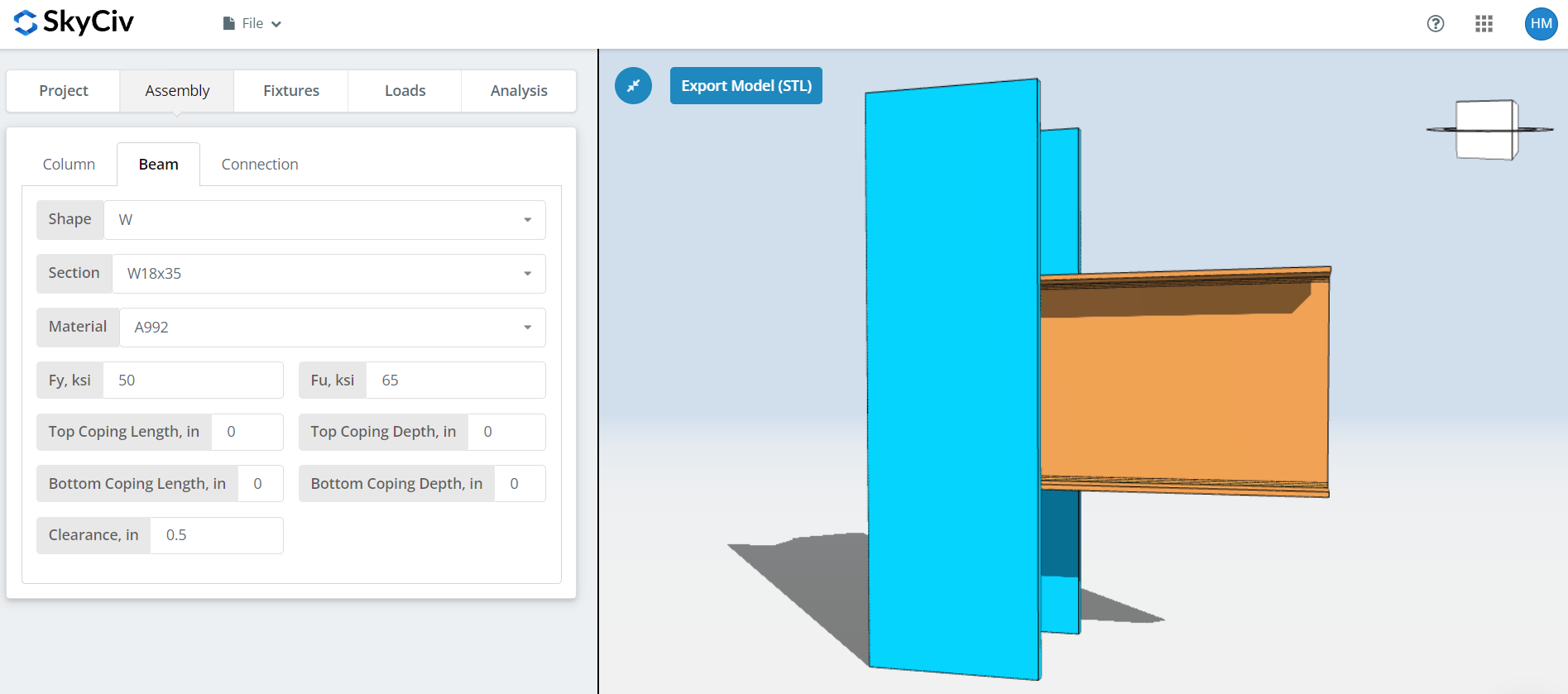

Beam Tab

Similar to the column tab, here you can specify the beam section/shape and material grade. In addition, you can also specify the cope dimensions as well as the beam clearance.

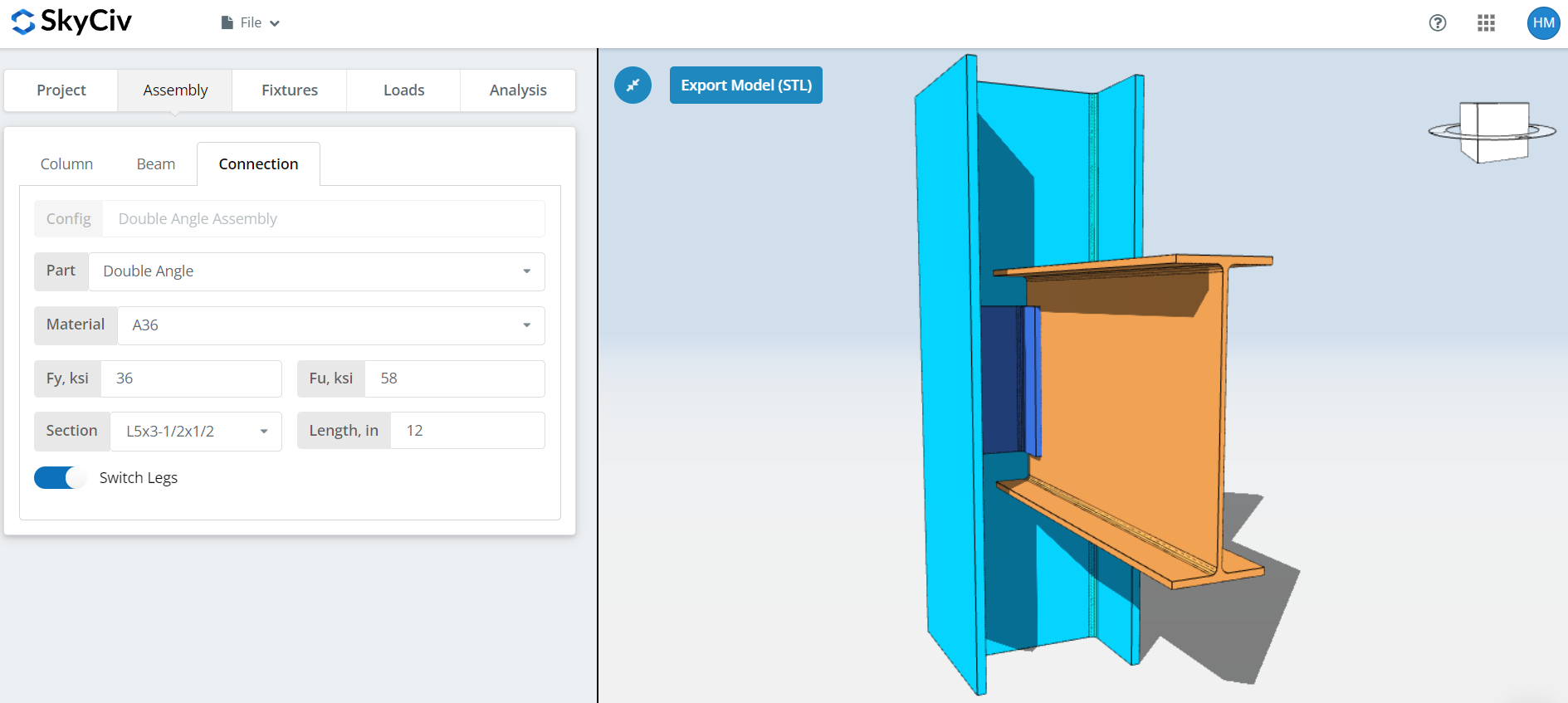

Connection Tab

Here you can specify the properties of the double angle. Material grade of A36 or A992 but you can also specify “Custom” and manually input Fy and Fu. Set the section size as well as its length. Note that you can also switch the legs if the chosen angle size have different leg sizes. For BCW, it is ideal to have the shorter leg attached to the column side since there is a very limited space there. Now don’t forget to look closely at the 3D renderer and make sure the angle dimensions make sense. Angle height should be within the beam depth and total angle width should not exceed the column T-dimension or the clear web depth.

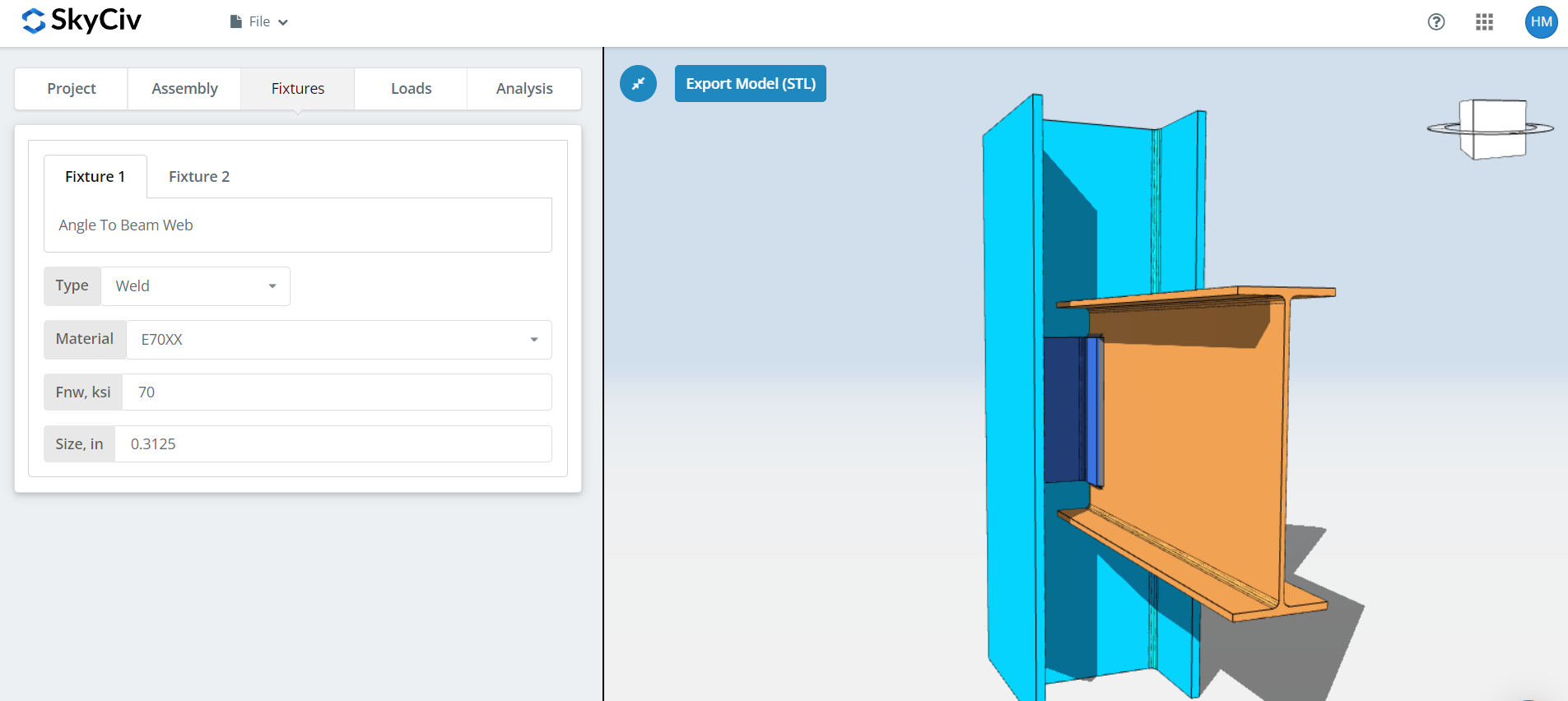

Fixture 1 Tab

Here is where you can specify the angle to beam web connection. You can either choose bolted or welded but for this demonstration, let’s choose a welded one. As mentioned, for BCW, a welded/bolted double angle connection is ideal due to the column webs limited space.

First, specify the weld material. There’s a couple of weld material options but if what you have is not there, you can use ‘Custom’ and manually input Fnw. And finally, don’t forget the weld size. Make sure the weld size is not larger than the angle thickness as there will be no room to complete the weld if so.

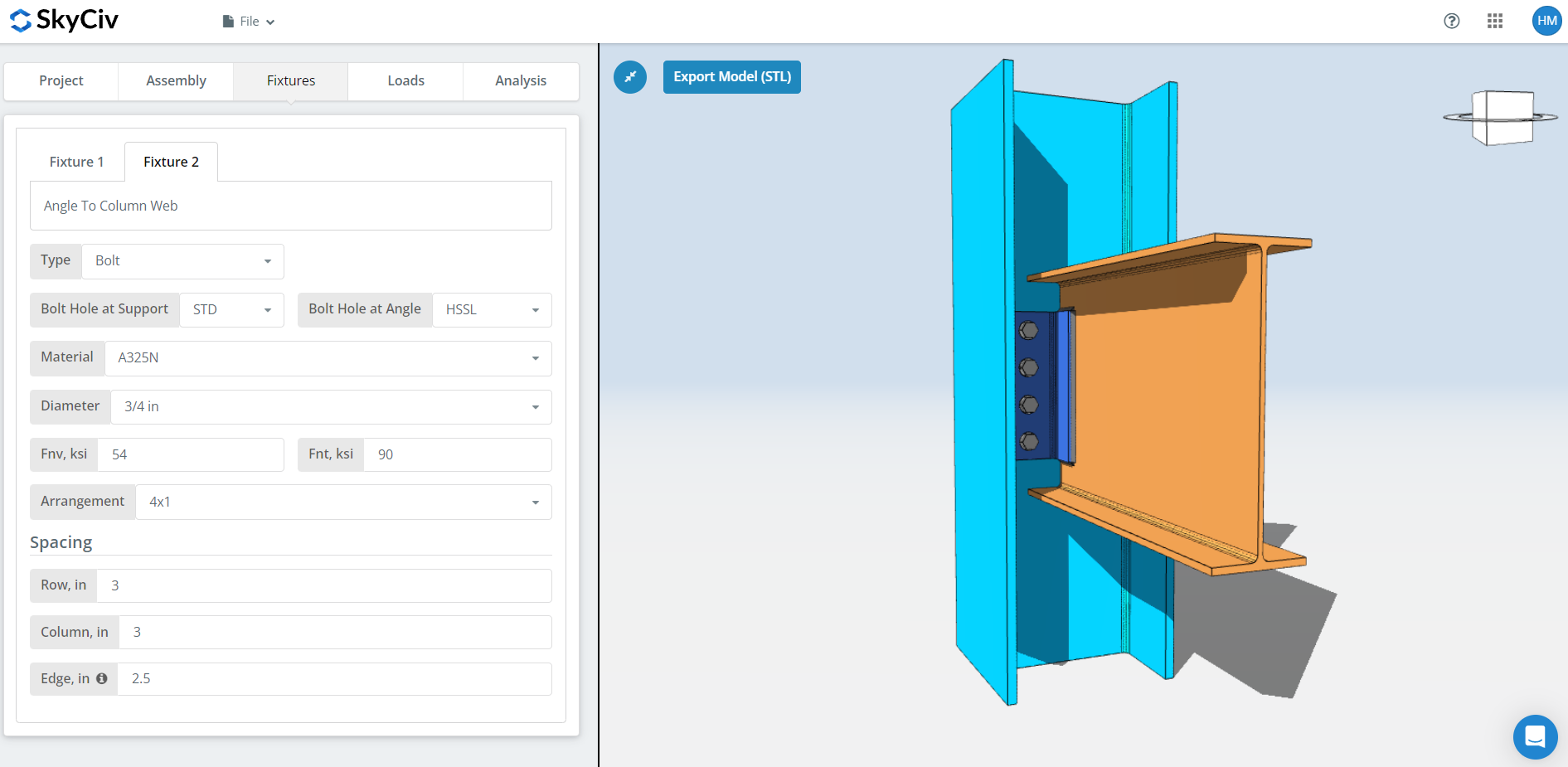

Fixture 2 Tab

Here is where you can specify the angle to support (girder web, column flange, or column web) connection. You can either choose bolted or welded but for demonstration, let’s choose bolted here.

First, specify the bolt hole types at both beam and angle. Fabricators usually prefer using standard holes (STD) at member and horizontal short-slotted (HSSL) holes at angle to allow better fitting at the field.

Next, select the bolt material or grade. You can choose either A307, A325, A490, or a Custom input. As for N versus X, X has a larger bolt shear capacity but you will have to make sure that bolt threads are excluded from the shear plane thus you will need to communicate this properly with the erector.

Next, specify the bolt diameter. You can choose from 5/8″ up to 1-1/2″ diameter or the equivalent metric units. Then, specify the bolt arrangement. You can choose up to 12 bolt rows and columns. Don’t forget to specify the bolt row and column spacing as well. Here’s a tip, you can use a larger bolt spacing instead of increasing the number of bolts if you need more bolt capacity. Just make sure the plate height still makes sense and within the allowable beam depth. Our bolt group strength utilizes the instantaneous center of rotation method (ICOR), which means you can specify any bolt spacing and capitalize its increase in bolt capacity. But, you need to make sure your fabricator is okay with variable bolt spacing. Some fabricators like using 3″ spacing typical. As for the “edge” input, this is the horizontal distance from the center of the beam to the nearest bolt.

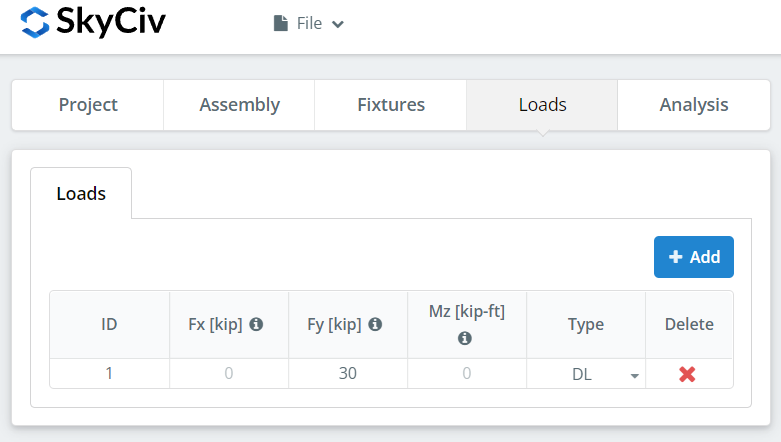

Loads Tab

Don’t forget to input the vertical shear load under ‘Fy’.

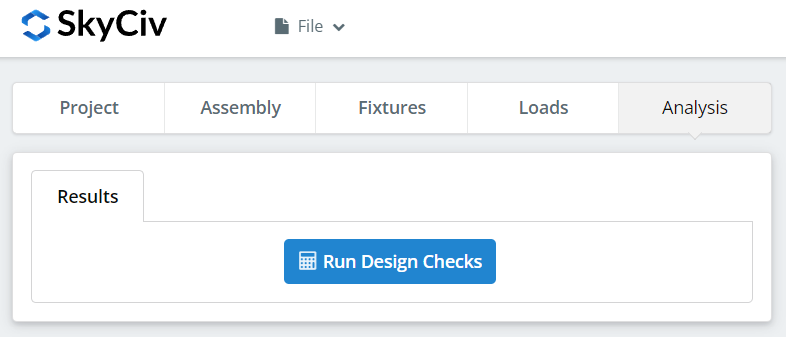

Analysis Tab

And finally, click “Run Design Checks”. If you missed any needed inputs on the previous tabs, this will notify you to fill in the missing inputs.

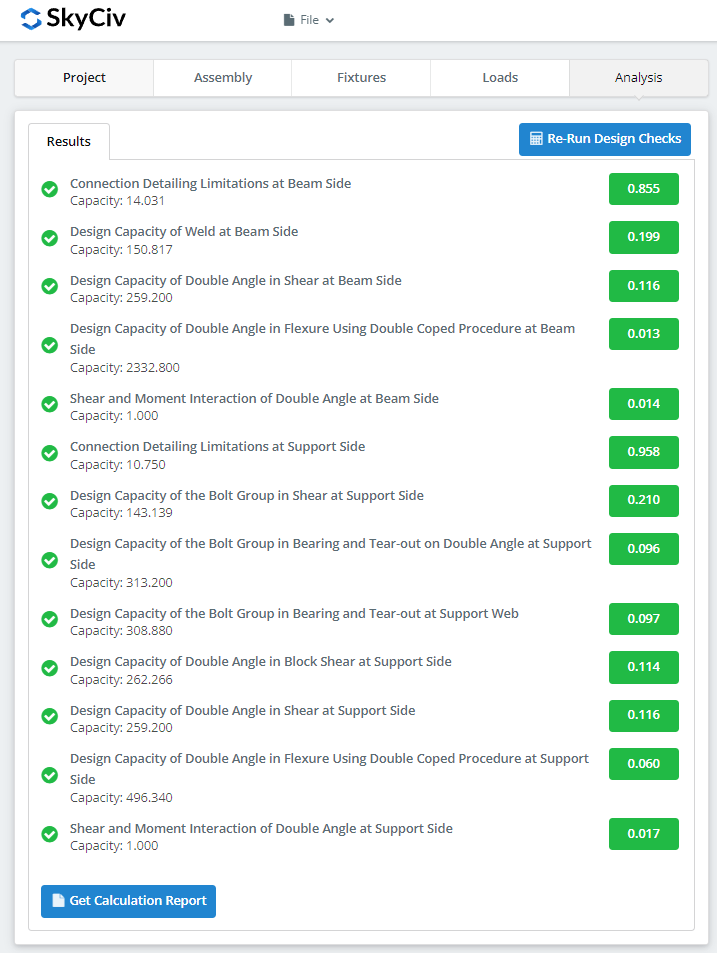

After clicking “Run Design Checks”, you can see a summary if your connection failed or not. If it failed, manually change the inputs in the previous tabs and then, click “Re-Run Design Checks”. When it’s finally okay, click “Get Calculation Report” to see the detailed report.

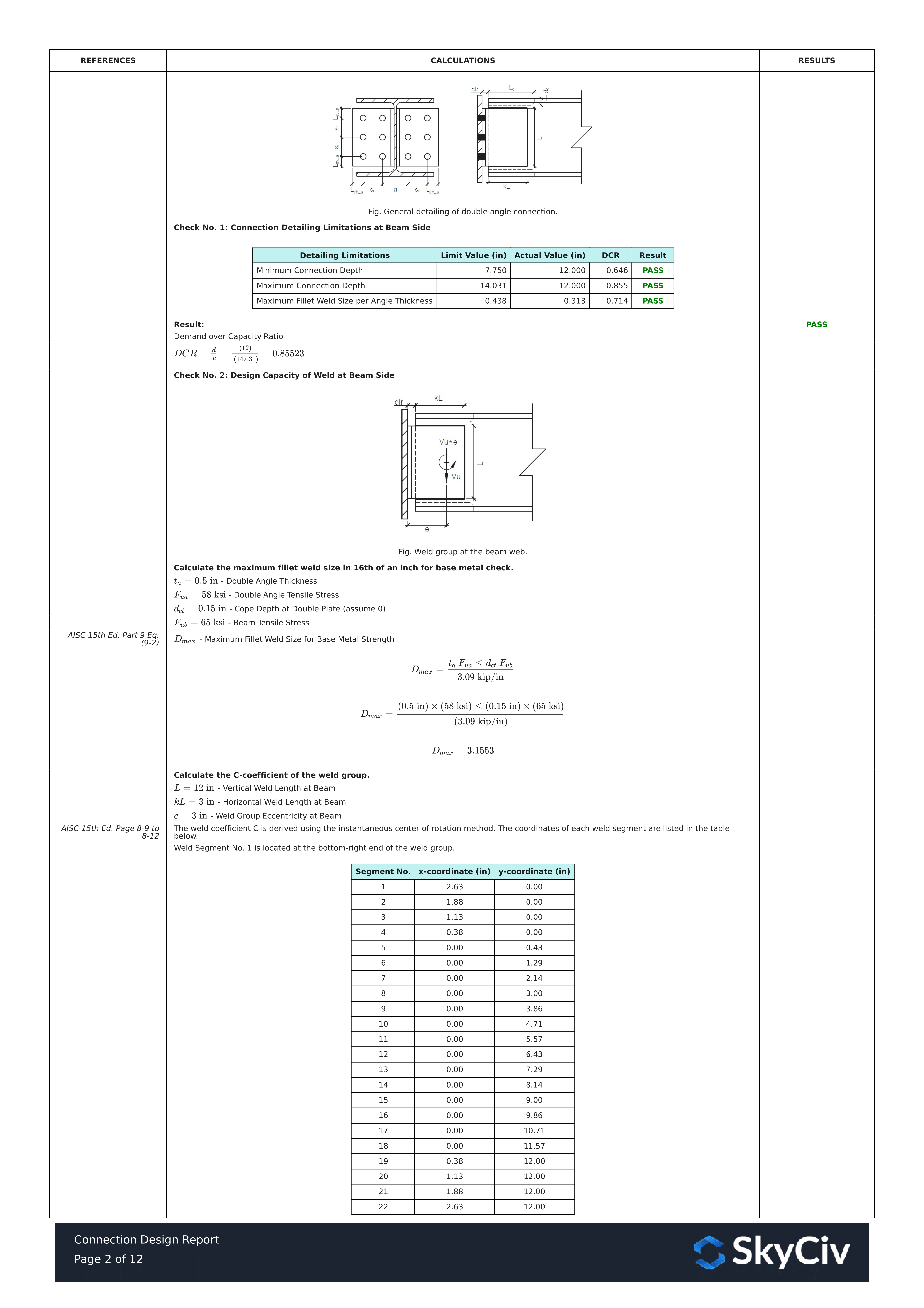

What you see above is a snippet of the detailed calculation report. As you can see, there is a reference to the AISC manual and/or specification. This should make it easier for the signing engineer to cross-check the calculations. Our calculations are very readable. It is written similar to how it’s written in the manual, specification, or design guides.

Here’s a PDF copy of the full detailed calculation report… Connection Design Report. Check it out!