Wählen Sie schnell offene Stahlträger aus und aktivieren Sie sie (OWSJ) vom Steel Joist Institute (SJI) Tabellen laden

Üblicherweise werden offene Stahlträger verwendet, vor allem in den Vereinigten Staaten, dank ihres hohen Festigkeits-Gewichts-Verhältnisses im Vergleich zu anderen Konstruktionsmaterialien und -elementen. SkyCiv gibt Benutzern die Möglichkeit, Mitglieder zu identifizieren und schnell die Kapazität aus einer Vielzahl von Serien zu überprüfen, die in den Lasttabellen von SJI aufgeführt sind.

Derzeit unterstützte SJI Joist-Serie:

- K-Serie

- LH-Serie

- DLH-Serie

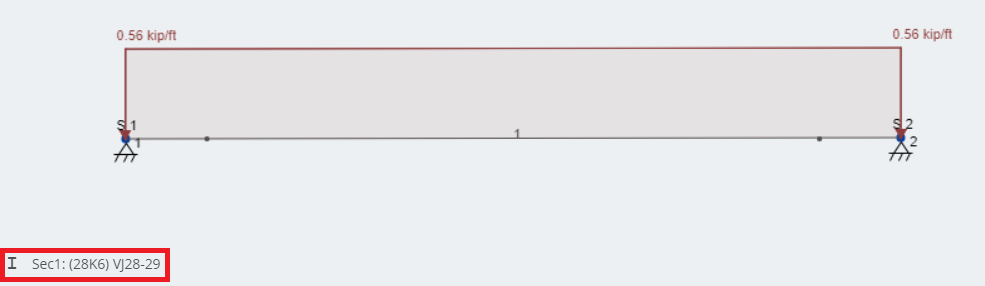

SkyCiv Structural 3D unterstützt derzeit die Konstruktion von Balken gemäß den Standardlasttabellen¹. Anschließend, Balken dürfen nur entworfen werden, wenn eine gleichmäßig verteilte Last auftritt (UDL). Wenn eine andere Lastart oder -variation verwendet wird, Structural 3D generiert eine Fehlermeldung.

Hinweis: Structural 3D wählt und überprüft die Balkengrößen mithilfe von GESAMT sicher (faktorisiert oder unfaktoriert) gleichmäßig verteilte Tragfähigkeiten (schwarze Werte in den SJI-Standardlasttabellen).

Hinweis: Bei der Auswahl des Balkentyps, Strukturelles 3D erzwingt die entsprechenden Endfixierungen (FFFRRR) damit die Analyse ausgeführt werden kann

Was passiert in Structural 3D??

Mitglieder in Structural 3D fungieren als extrudierte Abschnitte, die im Section Builder identifiziert werden. Die von SJI Because präsentierten Standardlasttabellen, weil die Balkenquerschnitte über ihre Länge variieren, SkyCiv verwendet die Virtual Joist-Bibliothek, um die Eigenschaften jeder Balkenbezeichnung abzuschätzen.

Structural 3D wählt basierend auf der ausgewählten Serie die richtige Balkengröße aus, Mitgliederspanne, und UDL-Größe. Anschließend wird der nächstgelegene entsprechende virtuelle Balken gefunden, um die verbleibenden Abschnittseigenschaften auszufüllen, damit die Strukturanalyse ausgeführt werden kann. Aufgrund der Einschränkungen bei der Analyse, Der Balken sollte keinen resultierenden seitlichen Kräften ausgesetzt sein.

So entwerfen Sie ein OWSJ in strukturellem 3D & Beispiel

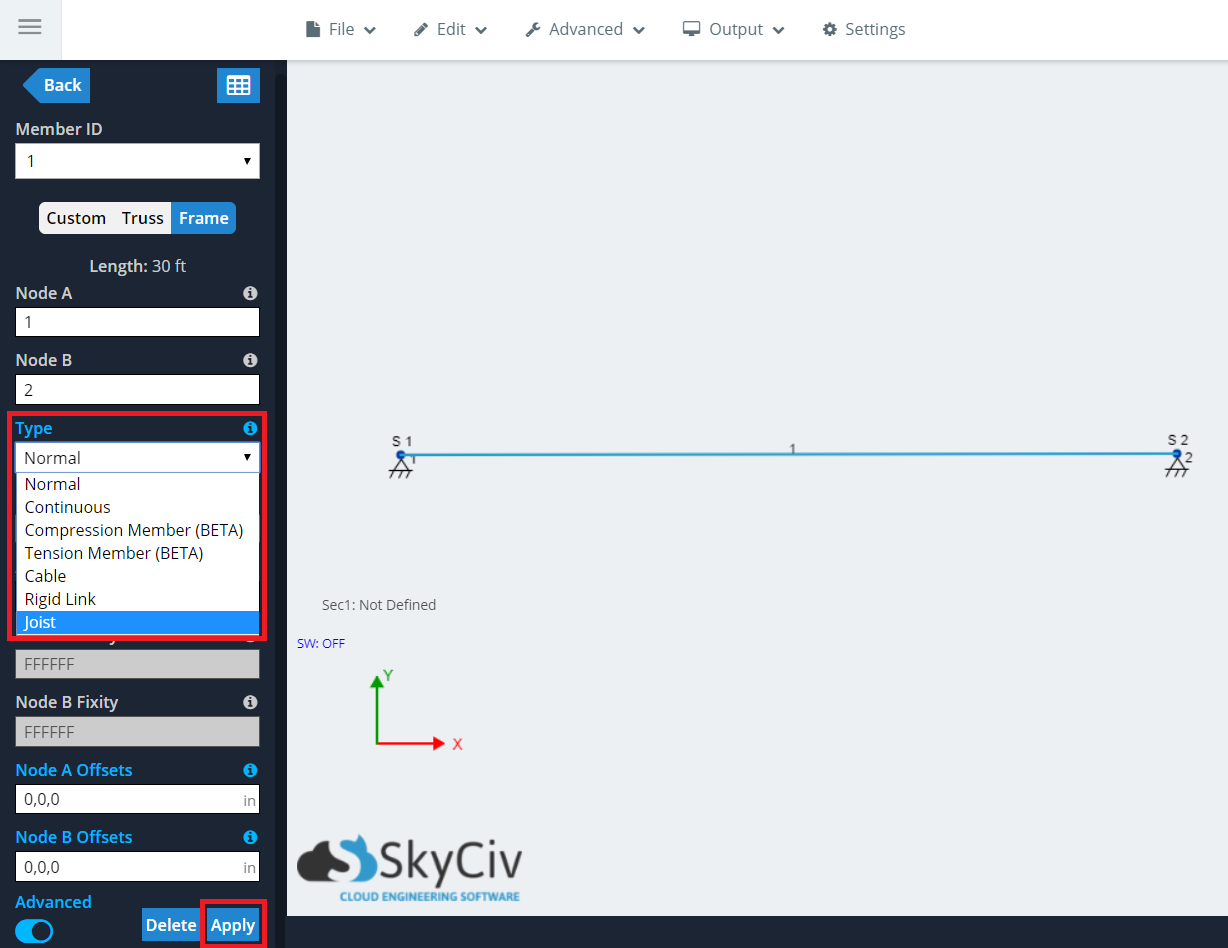

Finden Sie das Mitglied, das Sie entwerfen möchten, und schalten Sie die Option „Erweitert“ ein’ die Einstellungen. Ändern Sie den Typ des Mitglieds’ zu „Balken“.’ und klicken Sie auf „Anwenden“.. Einige Felder werden konsolidiert (wie Endbefestigungen)

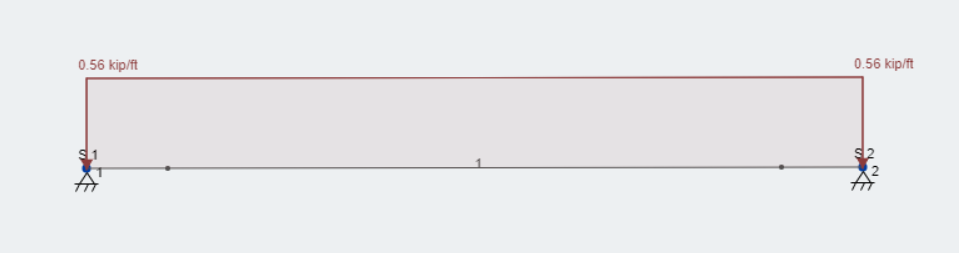

Wenden Sie eine Last an, sodass die resultierende Last eine UDL ist.

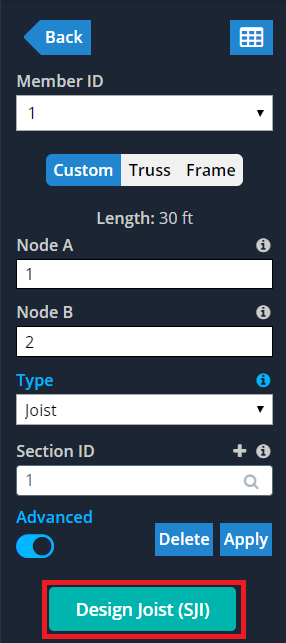

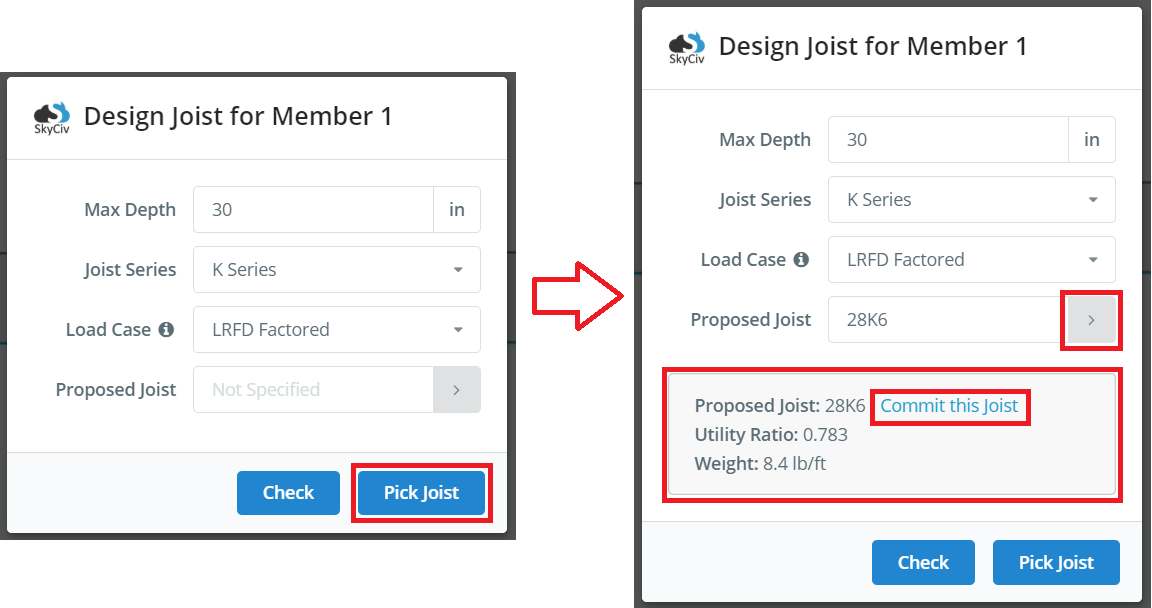

Klicken Sie auf „Träger entwerfen“. (SJI)’ Schaltfläche, um das Designfenster aufzurufen:

Legen Sie eine Tiefenbegrenzung fest, wählen Sie die Serie aus, Lastfall identifizieren, und klicken Sie auf „Träger auswählen“. Der ausgewählte Balken wird zusammen mit dem Einheitsverhältnis angezeigt. Um diesen Balken Ihrem Mitglied zu übergeben, Klicken Sie entweder auf das blaue Symbol „Änderungen übernehmen“.’ Text oder den grauen Pfeil rechts neben dem Feld.

Hinweis: Wenn keine geeigneten Träger vorhanden sind oder das Bauteil einer Lastschwankung ausgesetzt ist, Sie erhalten eine Fehlermeldung.

Die anschließende Balkenauswahl und die virtuelle Balkendarstellung werden als Abschnitt in das Projekt eingebracht und direkt auf dieses Element angewendet.

Hinweis: Balkengrößen können eingegeben/bearbeitet und mit der Funktion „Überprüfen“ individuell auf Design überprüft werden’ Taste. Stellen Sie immer sicher, dass Sie alle Änderungen an der Balkengröße übernehmen, um sie in Ihr Modell zu übernehmen.

Erfolgreiche Rückgabewerte

Die Rückgabewerte basieren auf den angegebenen Maß- und Lastbedingungen des Balkens in S3D.

Wählen Sie Retouren: Ausgewählte Balkenbezeichnung, Nutzverhältnis und Balkengewicht.

Überprüfen Sie die Rücksendungen: Vorgeschlagenes Nutzverhältnis des Balkens.

Fehlermeldungen

Fehlermeldungen basieren auf einer Verletzung bestimmter Kriterien in den SJI-Ladetabellen durch Benutzereingaben. Nachfolgend finden Sie Erläuterungen zu Fehlermeldungen und möglichen Lösungen:

[hr style=”1″ Marge=”40px 0px 40px 0px”]

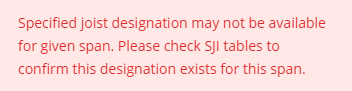

Erläuterung: Dies ist ein Fehler, der von der Prüffunktion zurückgegeben wird. Es tritt auf, wenn die vom Benutzer zur Überprüfung eingegebene Balkenbezeichnung in den SJI-Lasttabellen für die in S3D angegebene Spannweite nicht vorhanden ist.

Mögliche Lösungen:

- Überprüfen Sie, ob die von Ihnen vorgeschlagene Balkenbezeichnung korrekt und im richtigen Format eingegeben wurde, insbesondere, dass die Balkenreihe als GROSSBUCHSTABE eingegeben wird (K., LH, DHL vs, lh, Schulden)

- Überprüfen Sie in den SJI-Lasttabellen, ob Ihr vorgeschlagener Balken für diese Balkenspannweite verfügbar ist. Wenn nicht, wählen Sie einen gültigen Balken für die angegebene Spannweite.

[hr style=”1″ Marge=”40px 0px 40px 0px”]

![]()

Erläuterung: Dies ist ein Fehler, der von der Auswahlfunktion zurückgegeben wird. Aus den SJI-Belastungstabellen kann kein gültiger Träger ausgewählt werden. Dies tritt auf, wenn die angewandten Belastungsbedingungen die maximal zulässige Belastung für die vorgeschlagenen Balkeneigenschaften überschreiten.

Mögliche Lösungen:

- Überprüfen Sie, ob Sie die richtige Balkenserie auswählen. Allgemein, Balken der K-Serie sind am wirtschaftlichsten. Für längere Spannweiten sind linke und linke Balken erforderlich.

- Prüfen Sie, ob die maximale Tiefe erhöht werden könnte. Dies ermöglicht eine größere sichere Belastung des Balkens.

- Prüfen Sie, ob Ihr Lastfall korrekt ist. Auf ASD und LRFD basierende Designs können zu deutlich unterschiedlichen Ergebnissen führen, insbesondere faktorisiert vs. Unfaktoriert.

- Überprüfen Sie, ob die Größe und die Einheiten Ihrer aufgebrachten Last korrekt und beabsichtigt sind.

[hr style=”1″ Marge=”40px 0px 40px 0px”]

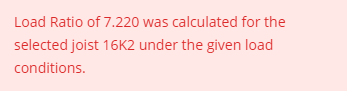

Erläuterung: Dies ist ein Fehler, der von der Prüffunktion zurückgegeben wird. Es tritt auf, wenn die aufgebrachte Last für den angegebenen Balken und Lastfall zu groß ist – alles vorbei 1.0 ist ein Fehlschlag.

Mögliche Lösungen:

- Überprüfen Sie, ob die vorgesehene Balkenbezeichnung korrekt eingegeben wurde.

- Prüfen Sie, ob Ihr Lastfall korrekt ist. Auf ASD und LRFD basierende Designs können zu deutlich unterschiedlichen Ergebnissen führen, insbesondere faktorisiert vs. Unfaktoriert.

- Überprüfen Sie, ob die Größe und die Einheiten Ihrer aufgebrachten Last korrekt und beabsichtigt sind.

[hr style=”1″ Marge=”40px 0px 40px 0px”]

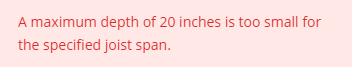

Erläuterung: Dies ist ein Fehler, der von der Auswahlfunktion zurückgegeben wird. Dies tritt auf, wenn die vorgeschlagene maximale Tiefe des Balkens für die ausgewählte Balkenspannweite und den ausgewählten Lastfall zu klein ist.

Mögliche Lösungen:

- Überprüfen Sie, ob die Höhe der Tiefenbegrenzung korrekt und beabsichtigt ist.

- Überprüfen Sie den Wert der Balkenspannweiten in S3D. Größere Spannweiten erfordern größere Tiefen, um strukturell realisierbar zu sein.

- Prüfen Sie, ob Ihr Lastfall korrekt ist. Auf ASD und LRFD basierende Designs können zu deutlich unterschiedlichen Ergebnissen führen, insbesondere faktorisiert vs. Unfaktoriert.

Verweise:

- Standardspezifikationen für die K-Serie, LH-Serie, Offene Stahlträger der DLH-Serie und für Balkenträger. SJI 100 (44Das D.). Florenz, SC: Institut für Stahlträger. 2015.