Wat zijn de meest voorkomende fouten in een boomilever-structuur?, en hoe u ze kunt testen

De Wetenschapsolympiadewedstrijd staat voor de deur! Het is tijd voor teams om hun ontwerpen te verzamelen en de best presterende structuren van voorgaande jaren te beoordelen. Dit jaar, we wilden dieper ingaan op de redenen waarom Boomilever kan falen en wat er gedaan kan worden om uw structuur te versterken.

Een Boomilever ontwerpen

Heb je al een structuur gemodelleerd in SkyCiv?? Wij raden u aan om eerst dit artikel te lezen: Hoe een Boomilever te ontwerpen in SkyCiv. Het laat u zien hoe u uw eerste structuur kunt modelleren en ontwerpen en hoe u de prestaties van uw Boomilever kunt simuleren voordat jij bouwt het!

In het volgende artikel wordt besproken hoe u uw structuur kunt testen en analyseren, zodat u problemen in uw model van tevoren kunt simuleren en opsporen.

Ons ontwerp

Het belangrijkste onderdeel van uw ontwerp is de manier waarop u uw leden indeelt. Ga je een Truss gebruiken?? Welke stijl van Truss? Dit heeft de grootste impact op zowel de prestaties van uw constructie onder belasting als op het totale gewicht. Het is de allerbelangrijkste beslissing die u moet nemen.

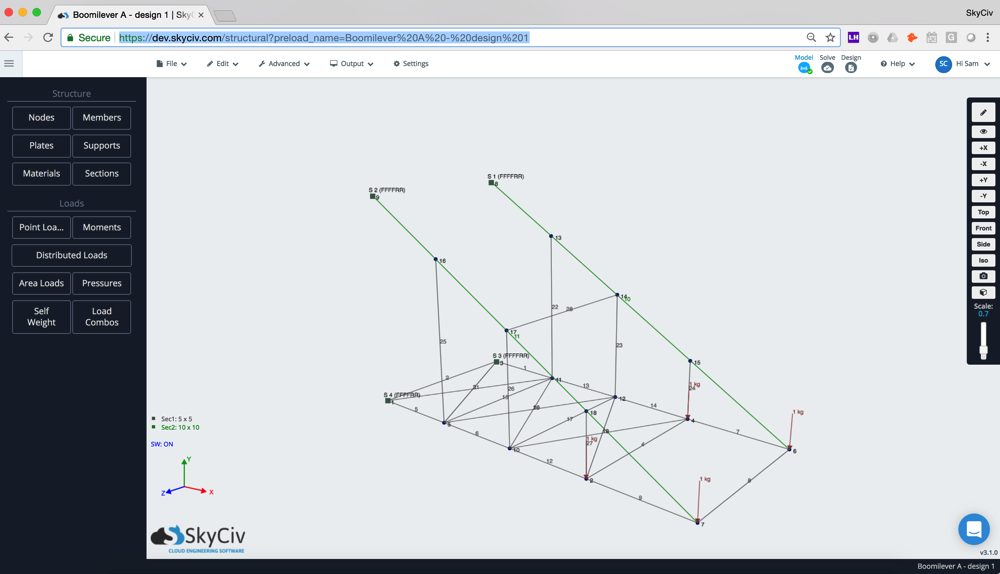

In dit artikel, we gaan ons ontwerp baseren op het volgende vereenvoudigde ontwerp:

Dit bestaat uit de volgende elementen:

Bron: Boomilever Wiki

A: Ondersteuning/basis

B: Spanningsleden

C: Distale uiteinde

D: Compressie dwarsbalken

Laten we nu eens kijken naar alle verschillende manieren waarop deze leden kunnen falen, en hoe we ons ontwerp kunnen helpen versterken.

Mislukkingsgevallen

Compressie mislukt

Compressiekrachten zijn de krachten die samendrukken het lid, of verbrijzeling naar binnen.

We willen een faalcriterium kiezen dat we kunnen gebruiken. Uit ons artikel weten we dat de Compressiestoring De stress van balsahout is aanwezig 7 MPa. Omdat hout een anisotroop materiaal is, de sterkte hangt af van de kwaliteit van het hout en de nerfrichting ervan, maar onze aanname van faalstress zal een goede vuistregel zijn om in dit ontwerp te gebruiken

Ons doel is ervoor te zorgen dat alle compressie-elementen een compressiespanning hebben die niet groter is dan 7 MPa. Het is onwaarschijnlijk dat het lid zal falen als gevolg van pure compressie, maar dit is een belangrijk concept om te begrijpen en is belangrijk voor de onderstaande controles.

Spanningsmislukking

Trekkrachten zijn de krachten die induceren spanning binnen het lid, of naar buiten trekken

Balsahout is bij trek twee keer zo sterk als bij druk. Het is zeer onwaarschijnlijk dat de constructie zal bezwijken als gevolg van pure trekkrachten. Dit kunnen we buiten beschouwing laten als faalcriterium.

Foutcontroles

1. Buigspanningsfalen

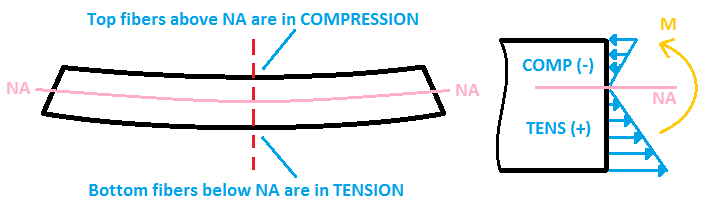

We beginnen met buigspanning, omdat dit een veelvoorkomend geval van falen is. Zoals de naam al doet vermoeden, dit gebeurt wanneer het element loodrecht op zijn neutrale as wordt belast (NA) het zal beginnen te buigen, waardoor een verdeling van de spanning langs de dwarsdoorsnede van het element ontstaat. Een duidelijk teken dat er buiging optreedt, vooral in hout, als de doorbuiging van het element langs zijn overspanning ten opzichte van zijn oorspronkelijke vorm.

In ons geval, alle houten delen zijn recht vóór het laden, dus elke doorbuiging vertelt ons dat het lid buigt. Een lid dat buigspanning ervaart, ziet er ongeveer zo uit:

De bovenkant van het lid is in compressie (-) en de bodem (+) zijn in spanning. De “M” is de positieve momentkracht die in dit geval de spanningsverdeling induceert.

Hoe u een buigfout kunt identificeren

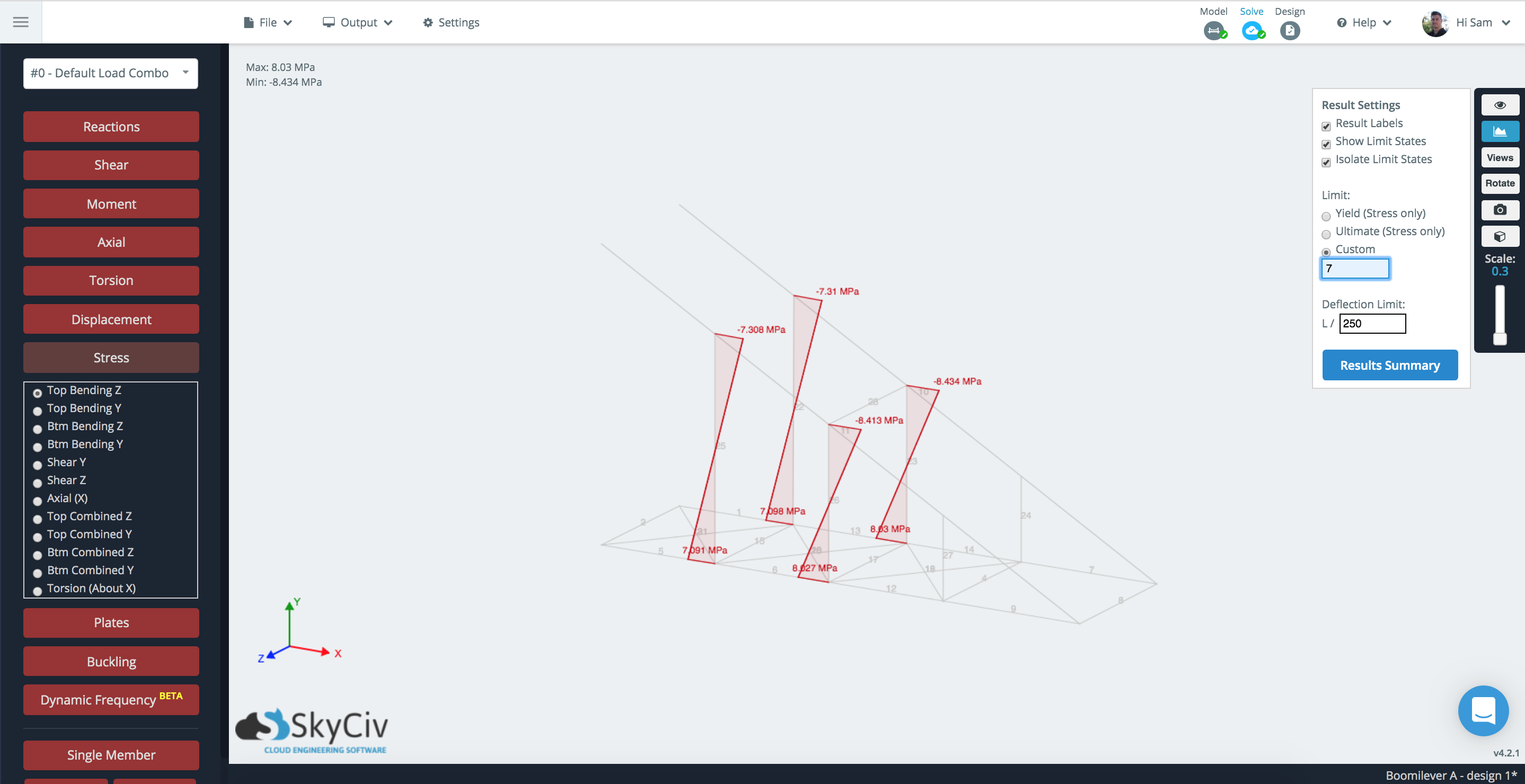

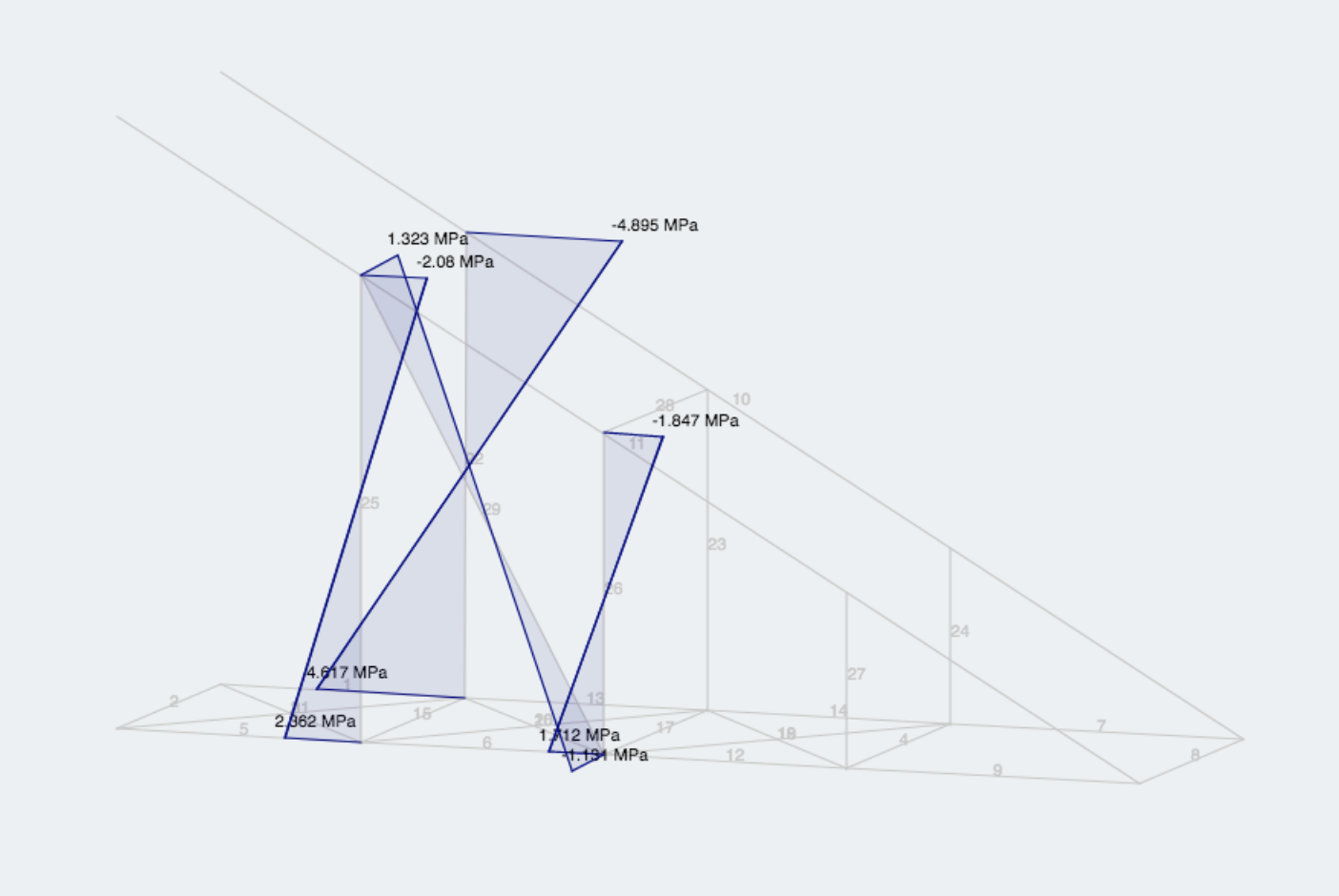

Na het uitvoeren van de analyse van de Boomilever in Structureel 3D, wij opereren vanuit de nabewerking, of Venster oplossen. U kunt gebruik maken van de Zichtbaarheidsinstellingen aan de rechterkant van het scherm om enkele weergave-/filteropties weer te geven.

Ons doel is om te controleren en ervoor te zorgen dat de drukspanning als gevolg van buiging niet wordt overschreden 7 MPa. Gebruik het recht Resultaatzichtbaarheid optie om eventuele spanningen hierboven weer te geven 7 MPa:

Dit type storing is te zien in de volgende video:

De video laat zien dat de stutten die de trek- en compressiekoorden verbinden, zullen bezwijken door een combinatie van buigen en knikken. Dit valt samen met ons model hierboven, dat laat zien dat de belangrijkste faalpunten bij deze verbindingen liggen.

Hoe te versterken tegen buigfalen

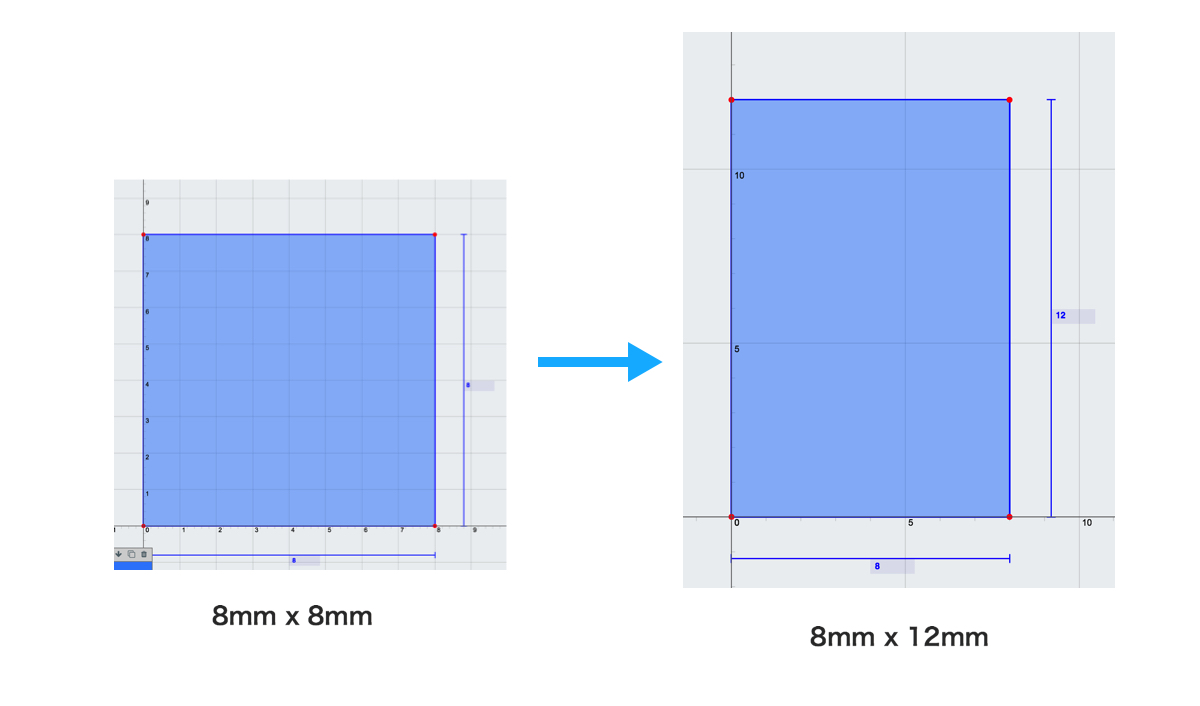

Hier kunnen we zien dat er vier leden zijn die gevoelig zijn voor buigfouten – omdat hun negatieve waarden onze compressielimiet van overschrijden 7 MPa. Nu ik deze zwakkere leden heb geïdentificeerd, Ik kan ze versterken door de sectiehoogte te vergroten:

De toename in hoogte van het lid zal zijn traagheidsmoment vergroten, een doorsnede-eigenschap die rechtstreeks verband houdt met de sterkte van de doorsneden. In dit geval, naarmate de hoogte van het lid toeneemt, buigspanning neemt af, en vice versa. Stel je voor dat je hetzelfde stuk hout probeert te buigen, maar met deze twee vormen, die moeilijker te doorbreken zou zijn?

Door deze wijziging door te voeren, kon ik de hoeveelheid spanning veroorzaakt door buigkrachten terugbrengen tot maximaal ongeveer 6.7 MPa.

Andere optie, is om een dwarsbalk toe te voegen om de kracht over een ander lid te verdelen. Dit kan uw structuur zwaarder maken en heeft daarom niet altijd de voorkeur boven Option 1 (je zult het verschil moeten overwegen bij het toevoegen van één lid, in plaats van het vergroten van de sectiegrootte en het gewicht van meerdere leden. In dit geval, we hebben een verstevigingselement toegevoegd om de structuur te versterken:

klaarblijkelijk, eraan toevoegend dat één steunlid hielp de krachten gelijkmatiger over de drie leden te verdelen. Het verlichtte zelfs de buitensporige spanningen van de leden aan de andere kant (verlaagd van -7.31 naar -4.895 MPa). Let echter op, zoals getoond zal dit elke symmetrie in uw structuur verstoren.

Het patroon op deze steunleden (of vakwerkleden) hangt af van uw ontwerp. Hier zijn een paar soorten spanten en hun sterke en zwakke punten.

2. Mislukking van het knikken

Dit is een veel voorkomende fout bij slank, dunne leden. Knikken is de faalwijze van een structureel lid dat hoge waarden ervaart samendrukkend spanningen die een plotselinge zijwaartse afbuiging veroorzaken. Stel je voor dat je een lid zo naar beneden duwt, dan het schopt uit en stort zo in:

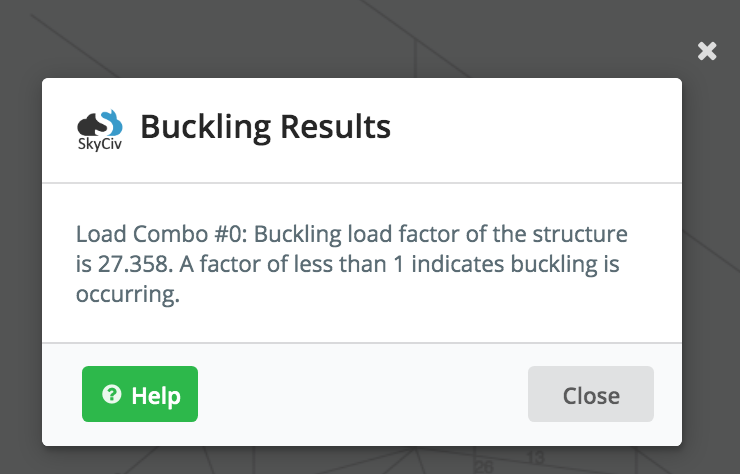

In het geval van onze boomilever, de relatieve verhouding tussen de afmetingen van de dwarsdoorsnede en de lengte van de staven maakt onze staven gevoeliger voor knikken. We kunnen testen op knik door een knikanalyse uit te voeren in de onderstaande software Oplossen. Hiermee wordt uw model gecontroleerd om te zien of er leden zijn die het risico lopen te knikken:

Zoals de waarschuwing suggereert, een getal kleiner dan 1 duidt op knikken. Dus onze Boomiliever is op dit moment in orde voor knikken. Als er problemen met de knik waren, ze zouden verschijnen als rode leden op de structuur, zodat u de kritieke leden kunt identificeren en uw ontwerp kunt wijzigen.

Notitie: Knikken is vooral belangrijk in de Towers-competitie van de Wetenschapolympiade, omdat er veel columnisten zijn.

3. Verbindingen/steunen

De basis en belangrijke verbindingen (zoals je distale uiteinde) moet ook van tevoren worden ontworpen. Dit deel van het ontwerp kan het succes van uw structuur maken of breken… letterlijk! Laten we eerst eens kijken naar het draagvlak. Dit verbindt twee leden die onder spanning staan met het moederbord. Je structuur mag aan de basis niet falen. Als je hier hulp bij nodig hebt, verwijzen naar Aia's gids over het ontwerpen van een boomilever, het heeft een geweldige gids voor een effectief basisontwerp dat ~ 1,5 g weegt en zal ondersteunen 18-19 kg.

TL; DR

We raden u aan het volgende te controleren om eventuele storingsgebieden van uw Boomilever te identificeren:

- Identificeer eventuele spanningsoverschrijdingen 7 MPa. Blader door de Spanning resultaten met een stresslimiet van 7 MPa om deze te identificeren. Als leden falen, je kan het proberen:

- Vergroot het oppervlak van de doorsnede

- Voeg steunelementen toe

- Wijzig structuurformatie of vakwerkstijl

- Voer een knikanalyse uit (vooral voor kolom- of verticale leden) en zoek naar een waarde groter dan 1

- Verkort de lengte van het lid

- Vergroot het oppervlak van de doorsnede

- Voeg onderweg steunleden toe

- Zorg ervoor dat je een sterke basis hebt, het mag niet de oorzaak van mislukking zijn

- Als het is, bekijk Aia's gids voor een sterk basisontwerp.