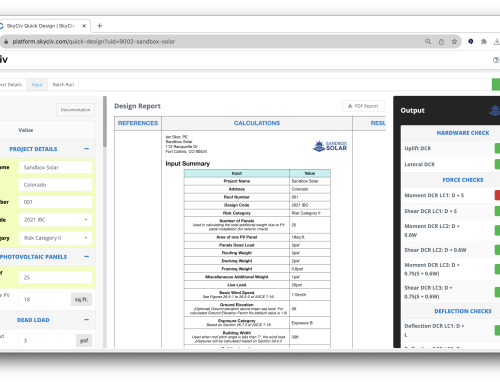

In this article, we will be going over the different types of Mass Timber and engineered wood products currently available in the market and discussing their uses, benefits, and drawbacks. If you want to learn a little bit more about what Mass Timber is, make sure to check out our Industry Insight featuring a Mass Timber expert, and our blog piece on Mass Timber as a Sustainable Building Material.

What is Mass Timber?

Mass Timber is short for "Massive Timber", which broadly speaks on different forms of engineered wood construction that perform well as structural elements. These engineered wood components come in a large variety, but in this article, we will be going over glue-laminated (glulam), cross-laminated timber (CLT), nail-laminated timber (NLT), and dowel-laminated timber (DLT). In general, Mass Timber is created by engineering pieces of wood together to create something that is greater than the sum of their parts. These engineered components end up functioning as beams, columns, and shear walls in a structure, depending on the product.

Types of Mass Timber Products

Glue-laminated (glulam)

Glue-laminated timber is a simple version of Mass Timber that is constructed by taking nominal, sawn lumber pieces, and laminating them together with moisture-resistant adhesives. These laminations can be all of the same species or they can be different, but they are chosen based on strength and other performance characteristics. In all cases, the grain of the wood coincides with the long or length dimension of the timber piece.

Usually, glulam members are used primarily as beams, since they strongly resist flexure perpendicular to their length. Specifically, they are commonly found in use cases where they sit exposed to the inhabitant of the structure. Because they are length-wise members, they can also make up members of a truss. Additionally, glulam 'panels' can be created to be used as decking, or curved to suit some interesting geometries.

Per the APA, standard glulam members range from 6 inches to 72 inches (wow!) in depth and 2.5 inches to 10.75 inches in width. In general, glulam members are some of the most common Mass Timber products you will find. See Figure 1 for context on what glulam members look like.

Figure 1: A pair of glulam beams (kalesnikoff.com).

Cross-Laminated Timber (CLT)

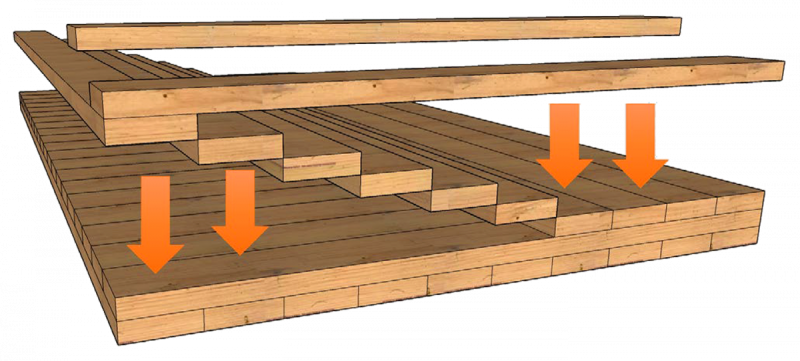

Glulam members, Cross-Laminated Timber uses the same lamination techniques as glulam members, but with additional layering and complexity. CLT is made first by laminating dimension lumber together side by side to create a layer, then by laminating layers together to create a CLT panel. Usually, CLT panels come in three, five, or seven layers of dimension lumber, which alternate direction by 90 degrees between each layer. These panels offer a large amount of strength and rigidity and are obviously found in panelized applications. Areas like walls, floors, and roofs are where you will find these panels.

As a slab or wall, CLT can offer two-way span capabilities thanks to the alternating of layer direction within a panel. In newer applications, it is being added to concrete as a composite building component. Check out the figure below depicting the construction of a CLT panel. Usually, CLT layers range between 5/8 inches and 2 inches thick.

Figure 2: Depiction of the cross lamination process of a CLT panel (www.sterlingsolutions.com).

You can read more in-depth about CLT in our blog piece Everything You Need to Know About CLT

Nail-Laminated Timber (NLT)

The idea of NLT is more than a century old but is seeing a resurgence in the Mass Timber industry. The geometry of the NLT construction is similar to glulam because you are laminating dimension lumber on top of one another. The main difference is that the laminations are held together by layers of nails, and the number of layers is significantly higher. This ends up giving the NLT more of a panelized application instead of a beam, column, or individual member one. Thus, it is used in similar ways as CLT: floors, walls, decks, roofs, etc.

Due to the panel layers all spanning in a single direction, a unique application using NLT panels is for curves, where the difference between each layer can be offset to fit the curve. Additionally, NLT panels are different because they can technically be created on site instead of only at a manufacturing site, so there is some flexibility in usage there. Check out figure 3 for a live depiction of the construction of an NLT panel.

Figure 3: Depiction of the nail-lamination construction a NLT panel (thinkwood.com).

Dowel-Laminated Timber (DLT)

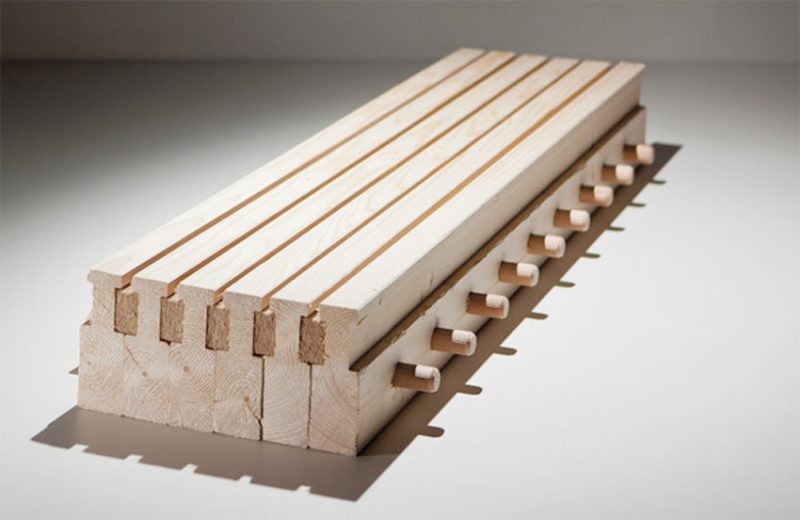

The last type of Mass Timber product that will be discussed here is DLT. It's usage is much more common in Europe than it is in the United States. Sticking with the theme throughout this article, the layers of the DLT are made up of dimension lumber laminated together, similar to the glulam and NLT products. What makes DLT different is that the layers are held together by hardwood dowels that run through all of the layers spaced at a certain interval.

The actual structural capacity of DLT panels is not commonly known through its presence in the building code, but the Timber Framers Guild offers information about the calculation. This means that its usage depends on the "Authority Having Jurisdiction" on a case-by-case basis. The largest difference and advantage of DLT panels is that they can house acoustic strips (see figure 4) for specific applications where that is necessary for an exposed wood look.

Figure 4: Example DLT panel with an acoustic profile on the architectural exposed side (treesource.org).

Sources:

1. “Cross Laminated Timber Construction: CLT Panel.” Think Wood, 30 Mar. 2021, https://www.thinkwood.com/mass-timber/clt.

2. “Dowel Laminated Timber Construction: DLT.” Think Wood, 30 Mar. 2021, https://www.thinkwood.com/mass-timber/dlt.

3. “Glulam: Laminated Timber Wood Beams & Columns.” Think Wood, 30 Mar. 2021, https://www.thinkwood.com/mass-timber/glulam.

4. “Mass Timber in North America - AWC.” American Wood Council, https://www.awc.org/pdf/education/des/ReThinkMag-DES610A-MassTimberinNorthAmerica-161031.pdf.

5. “Nail Laminated Timber Construction: NLT Lumber.” Think Wood, 30 Mar. 2021, https://www.thinkwood.com/mass-timber/nlt.