In structural engineering, a shear connection is a joint that allows for the transfer of shear forces between two members. So if a child member (for instance a beam) has some internal shear forces, these will be passed on as axial force into the column member. Typically, Shear Connections act as a pin (FFFFFR) as they do not take moment force like Moment Connections. (For more info, see Moment Connections)

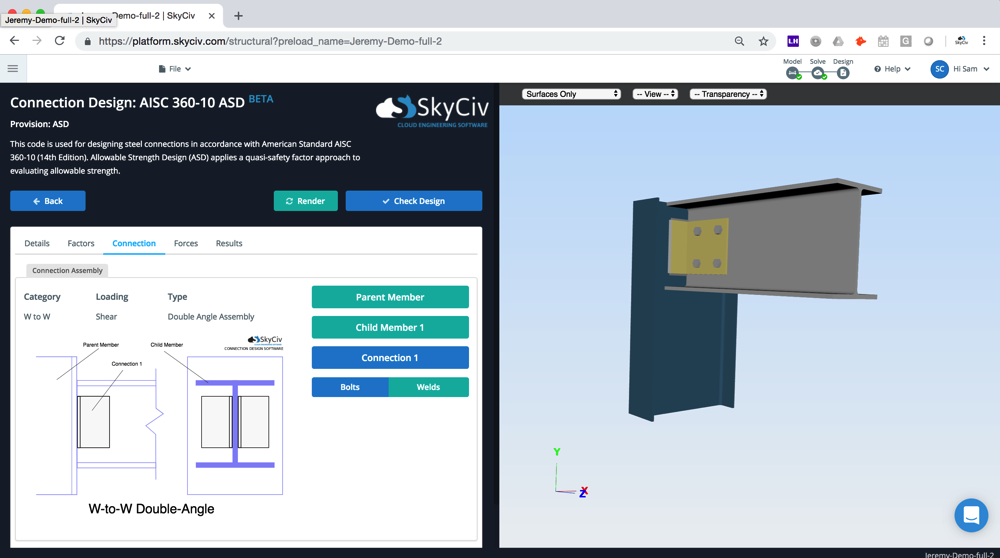

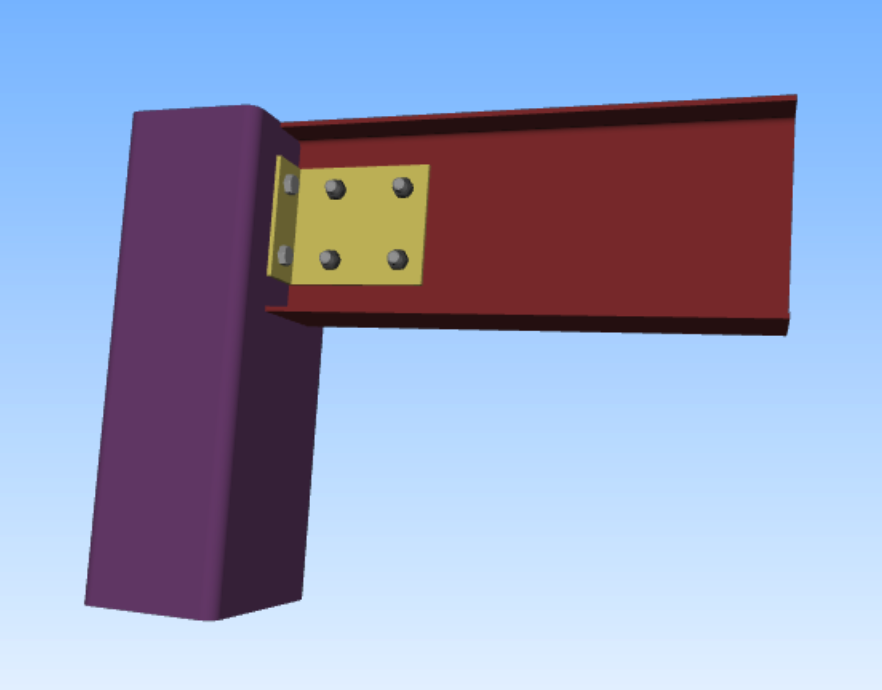

The shear force is often transferred with the aid of some plate, cleat or additional member that connects the two members. In the right example, taken from SkyCiv's Connection Design Software, you can see that any downward force will be passed onto the parent member via the (yellow) angle plate connecting the two members together. Since the plate is not rigidly welded to both members, the connection is still free to rotate - meaning it is not a moment connection. Normally, calculations performed on the Steel Connections follow a certain design standard (AISC, Eurocode, and AS4100) to ensure the calculation's reliability.

Shear connections are generally the most commonly used connections. If the frame is braced, a moment connection may not be required as the bracing provides adequate lateral stability. This can help reduce the reliance on moment connections, which are often more complex and costly

Single Angle Connection - An example of a Shear Connection. The lack of welds on top and bottom of the child (red) member means will not transfer moment force.

The most common types are the angle/plate connections, which either use an angle bracket or a plate to connect the flange of the parent to the web of the child member. Shear connections do not resits much moment forces as they are allowed some looseness to rotate. It is one of the main differences between a shear and a moment connection. It is worth noting that welded shear connections resist higher moment loads than bolted ones.

Angle Connection

Angle Connections are L-shaped brackets that hold the parent and child member together. The connection can have either one L-shaped bracket on one side or two brackets on both sides. Having two brackets (double angle connections), increases the rigidity of the connection but makes its stronger in resisting shear forces. The most common configuration of angle connections are that two sides of the connection are bolted the use of bolts reduces the cost.

Single Plate Connection

Much like the angle connections, Single Plate Connection uses a single plate to hold togehter the two memebers. It can be welded or bolted to the child member but is welded to the parent member. As it is welded to the parent member, it normally is more costly to use a single plate connection than a angle connection.

WT Connection

As the name implies, this connection uses a T-shaped section to join the parent and child member. This greatly increases its strength towards shear and moment loads. As such, the bearing strength of the connection becomes important.

Seated Connection

Seated Connections use L-shaped brackets to connect the parent and child member together. They differ from angle connections as they connect at the flange of both the parent and child members. However, similar to the angle connection, they can be welded or bolted. The are normally attached with a stability bracket which is connected at the web or the flange of the child member.

3D Representation of a Shear Connection - the yellow element is the angle that connects the Parent Member (Hollow Rectangular) to the Child Member (W-shape)

Source: SkyCiv Connection Design Software

We've discussed a lot about how a shear connection only transfers shear force. A moment connection will also transfer a moment force. Thing of it as a sort of hinge - a shear connection will allow it to rotate, but a moment connection will not. As mentioned above, shear connections are more common than moment connections as they are far cheaper and easier to design. Moment connections are only required when deemed absolutely necessary and insufficient lateral stability is provided in the building. See below a comparison table of shear vs moment connections:

| Shear Connection | Moment Connection | |

|---|---|---|

| Forces Transferred | Shear Only | Shear and Moment |

| Alternative names | Pinned, Hinge | Rigid, Fixed, Stiff |

| Rotation | Allows Rotation | Does not allow Rotation |

| Software Fixity Code | FFFFFR | FFFFFF |

The above info, screenshots and 3D models of shear connections are from SkyCiv Steel Connection Design Software. The software will run design checks for the various design codes, includine AISC 360-10 ASD and LRFD. With full rendering, CAD export and drawings. The software will also produce a step-by-step guide of the connection shear design calculations so that you can follow the steps it is taking.