K-Factor for Sheet Metal Calculator

The SkyCiv K-Factor for Sheet Metal is a free tool designed to help structural engineers and sheet metal fabricators who need to understand the precision and effects of their sheet metal bending designs.

About the K-Factor Sheet Metal Calculator

What is a K factor in sheet metal?

The K-factor in sheet metal is a ratio to determine where the neutral axis (where the material is neither in compression nor tension) lies within the thickness of the bent material. It is important to predict the bending allowance, which is the amount of material needed to achieve a desired bend. This is important for designers and fabricators to ensure the bent material meets specific fitment requirements.

In layman's terms, a sheet metal bend K-factor is a guideline which tells you how much the metal will stretch when you bend it. As you bend the metal, the inside gets compressed and the outside of the metal is in tension - at the middle we have our neutral axis where there is neither tension nor compression. The K-factor predicts exactly where this neutral axis inside the bent metal.

How do you Calculate K Factor?

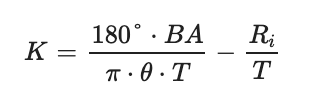

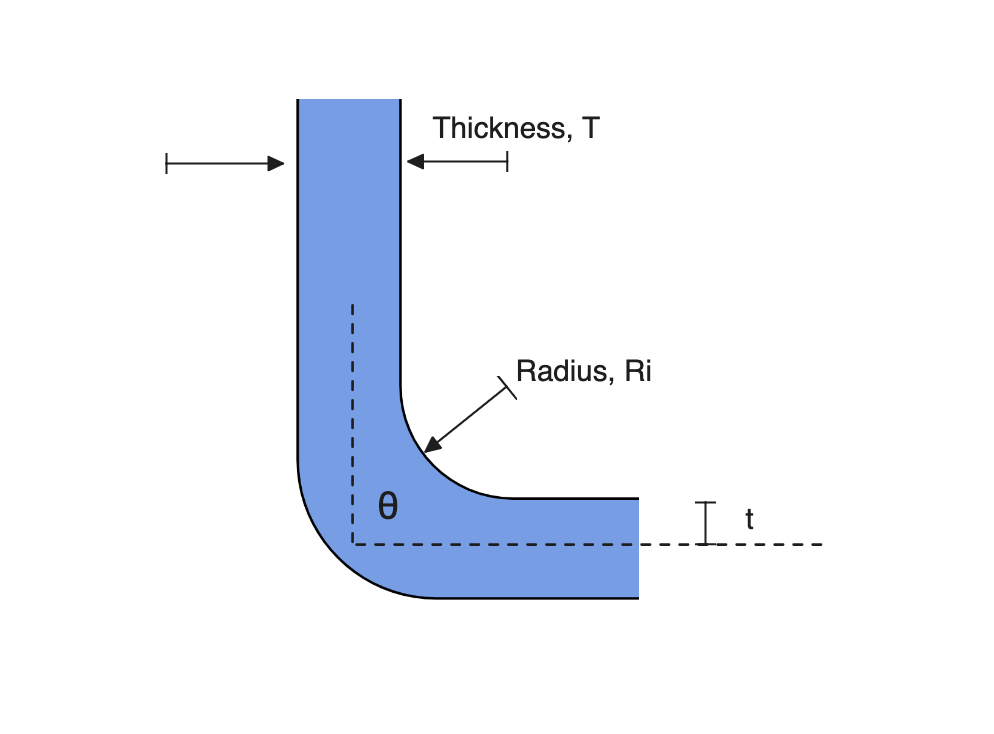

The K-factor calculations are quite simple, and can be summarized in the below formula:

- Material Thickness (T): The thickness of the sheet metal being bent.

- Inner Radius (Ri): The radius of the inner edge of the bend.

- Bend Angle (θ): The angle at which the sheet metal is bent. Note, this is in degrees (the actual formula will convert it to Radians)

- Bend Allowance (BA): The additional length of material required to accommodate the bend.

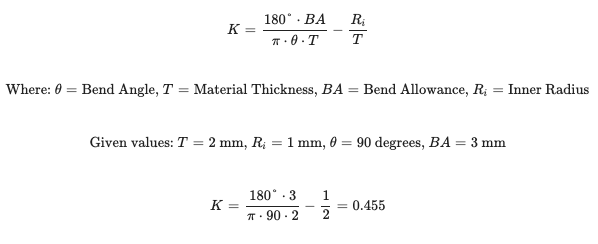

Sample Calculation for Sheet Metal K-Factor

Let's say you're a structural engineer designing a custom metal casing for a piece of industrial equipment. Precision is key, as the casing needs to fit snugly around the equipment with accurate dimensions for functionality and safety. Given the following example/inputs:

- Material Thickness (T): 2 mm

- Inner Radius (Ri): 1 mm

- Bend Angle (θ): 90 degrees

- Bend Allowance (BA): 3 mm

Plug these values directly into the above formula, note in the above formula the conversion of degrees --> radians is included, so you would enter θ directly as degrees

K = (180 * BA) / (π * θ * T) - Ri / T

K = (180 * 3) / (π * 90 * 2) - (1/2)

K = 0.455

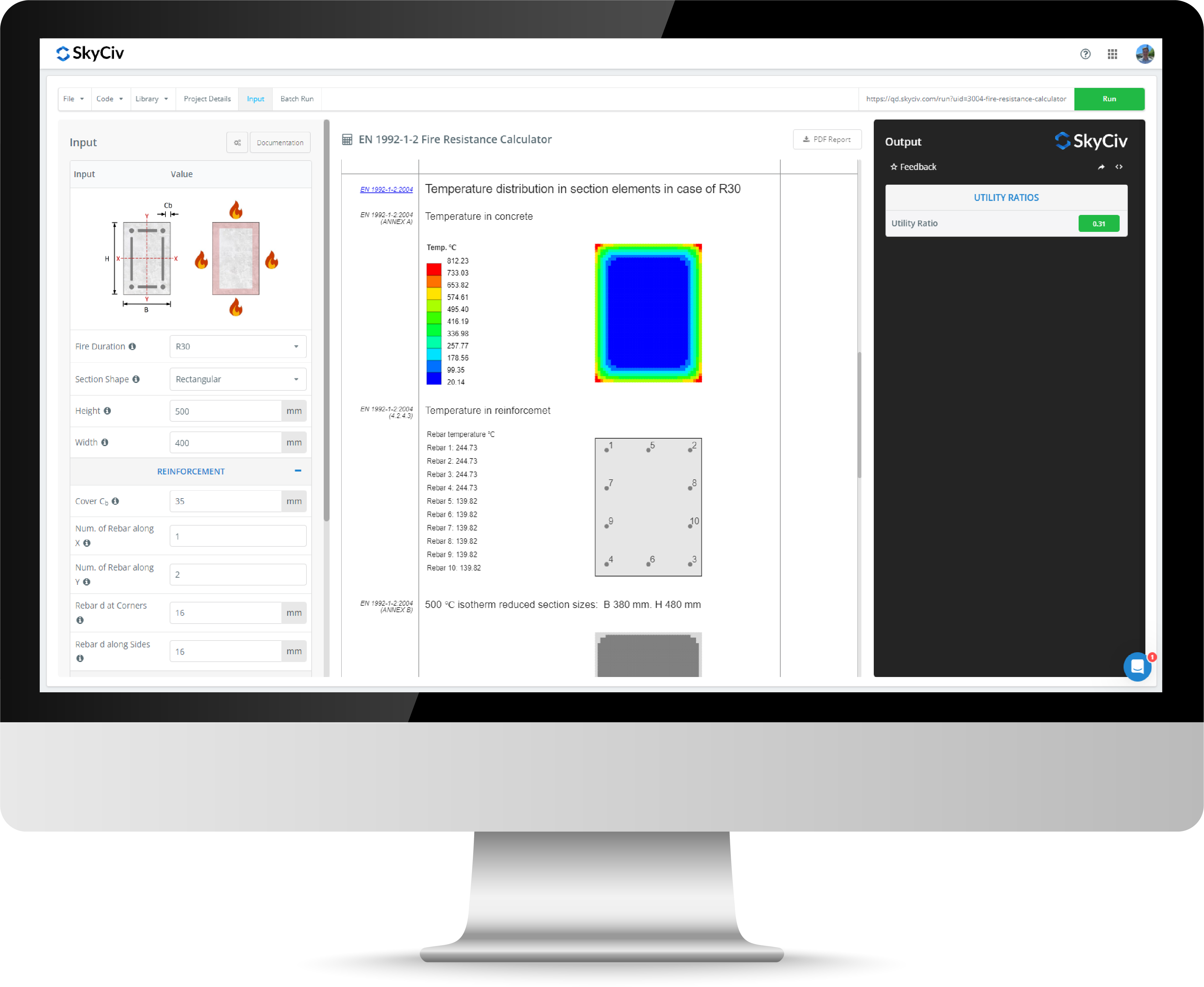

To compare and validate this answer, we plugged the same numbers in the above K-Factor calculator:

How to use the K-Factor Calculator?

The SkyCiv K-Factor Calculator for sheet metal is pretty straightforward and requires just a few simple inputs via the left panel, mainly:

- Material Thickness (T): The initial thickness of your metal sheet before the bend

- Inner Radius (Ri): This is the radius on the inside curve of the bend. A smaller radius implies a sharper bend

- Bend Angle (θ): The angle at which the sheet metal is bent

- Bend Allowance (BA): The extra length of metal needed for the bend. It compensates for the material that gets stretched in the bending process, ensuring that the dimensions of the finished part are precise and as intended.

Related Tools

Sheet Metal K-Factor Calculator FAQs

Usually an acceptable K-factor sits between 0.3 and 0.5. The above calculator will also calculate how far/close it is to these bounds to give you a sort of utility to understand whether or not your bend is within this guideline.

Ready to upgrade? Check out our flexible plans.