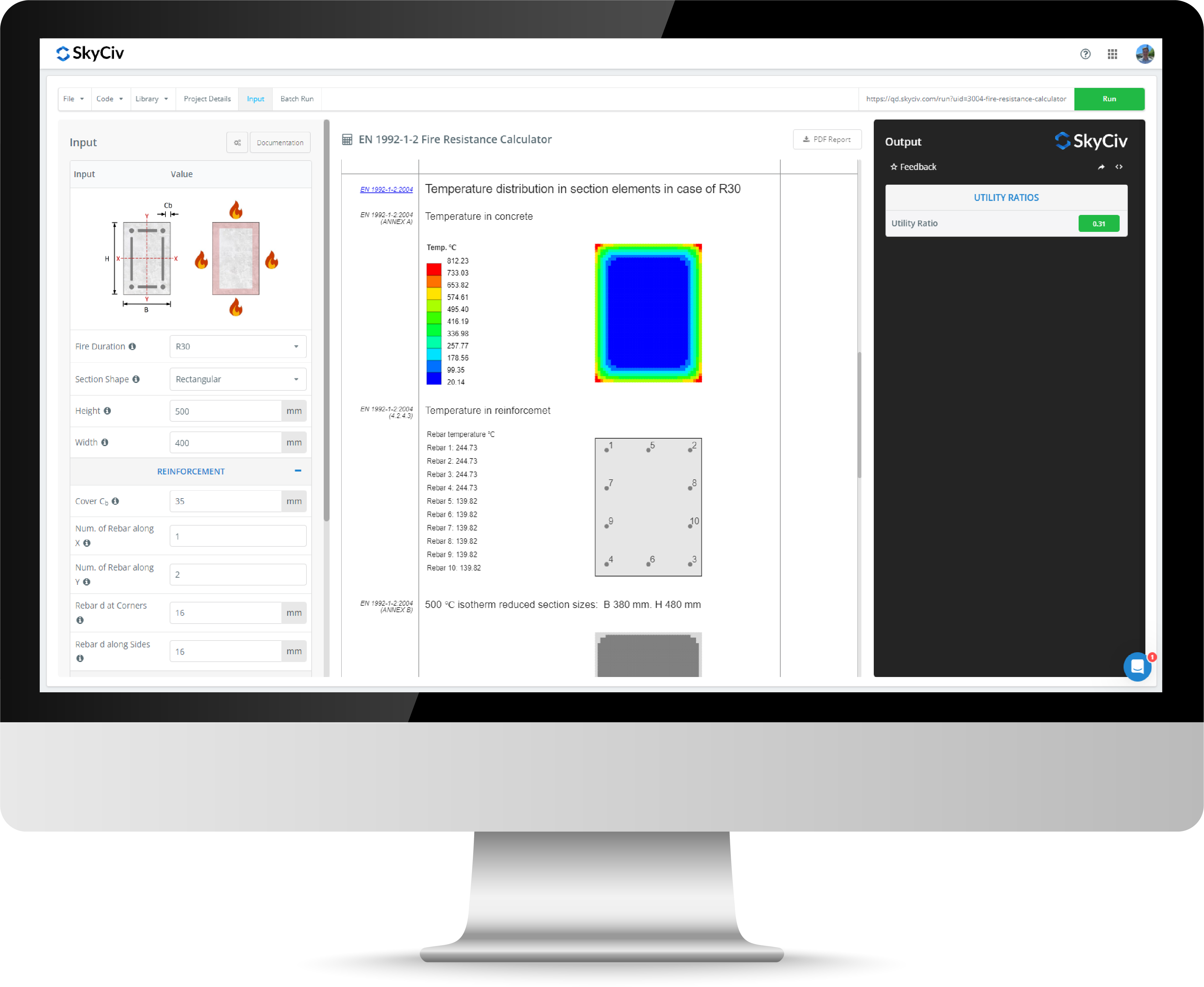

Weld Strength Calculator

The SkyCiv Weld Strength Calculator allows users to compute the weld capacity and shear strength for fillet welds in accordance with AISC 360-16, EN 1993-1-8:2005 and AS 4100:2020. The patterns available in the Blodgett Weld Capacity Calculator are based on the standard design formula that can be seen in Table 4 and 5 of the book Design of Welded Structures by Omer W. Blodgett. The weld calculator will return results including the applied force on the weld, the weld capacity and the utilization ratio of the weld. The tool can be used to determine the capacity for welding joints between steel plates, beams, columns and a range of typical section profiles.

Available Standards for the weld strength calculator:

- Australian Standards: AS 4100:2020 Weld Group Capacity Calculator

- US Standards: AISC 360-16 Weld Group Capacity Calculator

- Eurocode Standards: EN 1993-1-8:2005 Weld Group Capacity Calculator

- New Zealand Standards: NZS 3404:1997 Weld Group Capacity Calculator

This tool is part of the SkyCiv Quick Design module. Get started with the weld calculator below.

About the Weld Strength Calculator

What design methods are used in the Weld Strength Calculator?

Both Allowable Stress Design (ASD) and Load and Resistance Factor Design (LRFD) are available in the Weld Capacity Calculator. The ASD method considers the maximum allowable stress for a welded joint based on joint type and base materials, stresses are then checked to ensure they do not exceed the allowable values. In comparison, the LRFD method does not set a fixed allowable stress value but instead involves calculating a welded joint based on factors like the weld strength, material properties, and loading.

The Australian Standard for steel (AS 4100) uses a limit state design approach. With this approach loads are factored up into design actions and then resolved into equivalent shear stresses on weld groups. The weld shear capacity is then calculated and compared to the maximum shear stress on the weld group.

How is welding length calculated?

Generally welding length is calculated by measuring the linear distance along the joint between the two members that need to be welded. Other factors also need to be considered such as the thickness and type materials being joined. The geometry of sections can also physically limit a welders ability to reach spaces and may mean that certain sides of a section can not be welded.

Understanding the Weld strength formula

Weld strength is typically calculated as the shear strength of the weld in failing along the smallest possible shear plane.

For a fillet weld the shear area of the weld can be calculated by multiplying by the throat thickness of the weld. For an equal angle fillet weld this is the size of the weld divided by √2 . For an unequal fillet weld the calculation would some trigonometric calculations.

The shear strength is typically 0.6 x the ultimate tensile strength.

How to calculate weld strength?

Calculating weld strength depends on the type of weld but the general principal remains the same that we are checking for failure through the weakest plane. For a fillet weld we calculate the throat thickness of the weld using trigonometry but for other welds like a full penetration butt weld the failure plane will be different. If the butt weld is stronger than the steel material and the butt weld has a critical cross-sectional area greater than or equal to that of the base material we might not even need to calculate the strength of the weld at all and can just check the capacity of the base metal since it will be more critical.

How to calculate fillet weld strength?

The total capacity of a weld per unit of length is generally determined as:

0.6 * fu * tt

where:

- fu is the ultimate tensile strength of the weld

- tt is the throat thickness of the weld

How to calculate fillet weld strength?

Fillet weld strength is calculated the same as the weld strength is above.

How to calculate weld strength in AISC 360-16?

The AISC 360-16 calculates weld strength with the following equations:

LRFD: ϕ Rn = ϕ * Fnw * Awe

ASD: Rn / Ω = Fnw * Awe / Ω

where:

- Fnw is the nominal stress of the weld metal

- = 0.60 * FEXX * (1.0 + 0.50 * sin1.5(θ))

- where θ is the angle between the line of action of the required force and the weld longitudinal axis

- FEXX is the filler metal classification strength

- Awe is the effective area of the weld

- ϕ = 0.75

- Ω = 2

How to calculate weld strength in EN 1993-1-8:2005

The Eurocode 3 (EC3) calculates weld strength with the following equation for the simplified method:

Fw,Rd = a * fu / (0.577 * βw * γM2)

where:

- fu =nominal ultimate tensile strength of the weaker part joined

- a = throat thickness of weld

- for equal angle fillet welds = tw / √2

- where tw is leg length

- βw = Correlation factor for fillet welds

- 0.80 for S 235 steel grade

- 0.85 for S 275 steel grade

- 0.90 for S 355 steel grade

- 1.00 for S 420 steel grade

- 1.00 for S 460 steel grade

- γM2 = 1.25

Where the above calculation is a simplified weld strength approach, Eurocode also has a directional method for calculating weld strength requirements. The directional approach considers the normal stresses on the weld throat and the shear stresses on the weld throat differently allowing for higher strength in the normal direction. The formulation for assessing directional weld strength is:

[σ⊥2 + 3 (τ⊥2 + τ||2 )]0.5 ≤ fu / (βw * γM2)

and

σ⊥2 ≤ 0.9 * fu / γM2

where:

- σ⊥ is the normal stress perpendicular to the throat of the weld

- τ⊥ is the shear stress perpendicular to the axis of the weld

- τ|| is the shear stress parallel to the axis of the weld

In the case that we had no normal stresses on the weld we can see that if we rearrange the direct method formula we will get the same formulation as the simplified method.

How to calculate weld strength in AS 4100

The AS4100:2020 calculates weld strength with the following equation:

ϕ vw = ϕ * 0.6 * fuf * tt * kr

where:

- ϕ = reduction factor

- 0.6 for general purpose (GP) fillet welds

- 0.8 for structural purpose (SP) fillet welds

- fuf =tensile strength of weld metal

- tt = throat thickness of weld

- for equal angle fillet welds = tw / √2

- where tw is leg length

- kr = reduction factor for lap splice connections

- 1 for typical welds and lap slices less than 1.7 m in length

- 1.10 - 0.06 lw for lap splices between 1.7 m and 8 m in length

- 0.62 for lap splices greater than 8 m in length

What is a Weld Strength Calculator used for?

The SkyCiv WeldStrength Calculator is useful to determine what the maximum load a joint between two members can safely be expected to stand before failing. Checking weld capacity is a key part of the engineering process to ensure that connections are structurally sound and meet design standard requirements.

The SkyCiv Blodgett Weld Strength Calculator is useful in a range of structural engineering projects that may include building construction, bridge construction and many other infrastructure projects. Welding also has applications in automotive, aerospace, marine (shipbuilding), railway, offshore and mining engineering. Often due to the nature and safety requirements these industries have particular welding regulations that need to be followed.

When to use welds over bolts?

Welds have several advantages over bolted connections which are:

- No removal of steel material. Whereas welds only add material to the side of a member bolted connections will remove material from the steel section, reducing section capacity and introducing concentrated stress points in the member.

- Welds are stiffer than bolted connections. This can help if a structural engineer has designed a connection to be a fixed connection instead of a pin connection.

- Welded connections can provide higher strength since they provide a continuous joint. Bolted connections can have physical limitation on how many bolts can be provided due to spacing requirements and will only provide discrete points of restraint.

- Bolts extrude whereas welds can remain neat and hidden. Welds run along existing joints and are less visually intrusive than bolts which will be spread further away from the end of a beam and be less subtle than welds.

What is a weld treated as a line pattern?

A weld treated as a line pattern in a method to graphically represent weeds on engineering drawings. The above weld capacity calculator has twenty-one weld patterns available based on the Blodgett Weld Type outlined in the book Design of Welded Structures. These weld patterns represent a variety of different cross section types that are commonly found in structural members.

The AS 4100 weld capacity calculator also allows importing the dimensions of typical steel sections and editing weld patterns into custom arrangements. Calculations for custom weld patterns are resolved using the parallel axis theorem and elastic theory.

Types of welding joints

There are multiple types of welding joints available that are used in structural engineering. Some common types of joints include Butt Joints, T-Joints, Lap Joints, Corner Joints, Edge Joints, Groove Joints, Plug Welds, Filleted Joints, Spot Weld and Seam Welds.

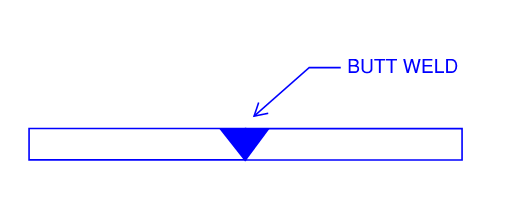

What is a butt joint weld?

A butt joint weld is used to join two pieces of metal end-to-end that are parallel to each other.

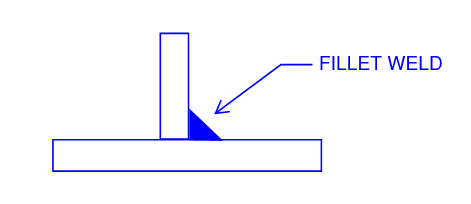

What is a fillet joint weld?

A fillet joint weld is a weld between two perpendicular (or near perpendicular) members. They are common in baseplates and beam to column connections.

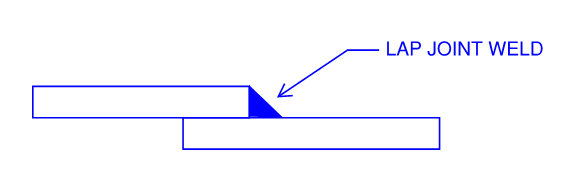

What is lap joint welding?

A lap joint weld is used to weld two overlapping pieces of metal that are parallel to each other and sitting flush. Fillet welds are used on one side or both sides of the connection.

Weld Strength Calculator FAQs

What is Blodgett Welding?

Blodgett Welding is based on Omer W. Blodgett book Design of Welded Structures.

We can also design for custom arrangements by using the second moment area of line welds and then using the parallel axis theorem to find the result. Blodgett Welding has simplified different arrangements into a series of simple to apply formulas to reduce the amount of steps in calculations.

What weld section properties are required?

The SkyCiv Weld Capacity Calculator takes properties include the ultimate strength of the weld, the weld size and the depth of the weld.

What results are available for the Blodgett Weld Strength Calculator?

The weld capacity calculator returns a weld capacity result as well as a utilization ratio for the welded connection. In addition to this the following results are also provided:

- Preferred Weld Size

- Member Weld Capacity

- Fillet Weld Capacity

- Maximum Effective Weld Size

- Maximum Force per Unit Weld

What weld loads are required?

The SkyCiv Weld Capacity Calculator requires the applied force along the x, y and z directions as well as the moment about the x and z axis.

What unit system is available?

Currently only the imperial unit system is available for the AISC 360-16 calculator and only the metric system is available for the AS 4100 calculator and EN 1993-1-8 weld strength calculator.

Related tools

Ready to upgrade? Check out our flexible plans.