Connecting medium (fasteners / fixtures)

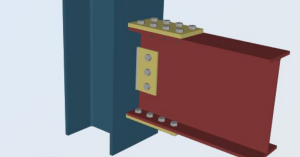

In modern times, the most common types of connecting mediums are welds and bolts. Welds offer simplicity, whilst bolts off economical installation in the field. Rivets have historically been used, but have been mostly replaced by bolts for a number of reasons. These include:- Bolted connections: the most economical option but also the least robust. Learn more about this type of connections in our bolts and bolted connection article

- Welded connections: strongest but the most expensive option.

- Riveted connections: hybrid of bolted and welded, offering a balance of strength and cost

Learn more about types of fixtures in connections.

Learn more about types of fixtures in connections.

Internal forces the connections are expected to transmit

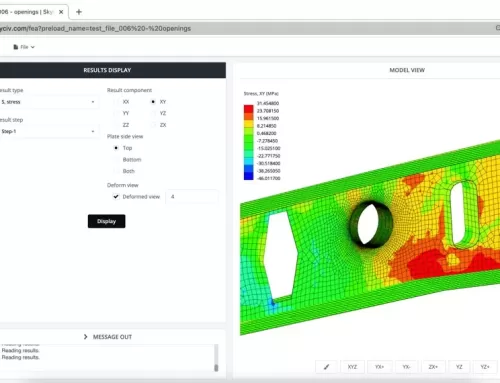

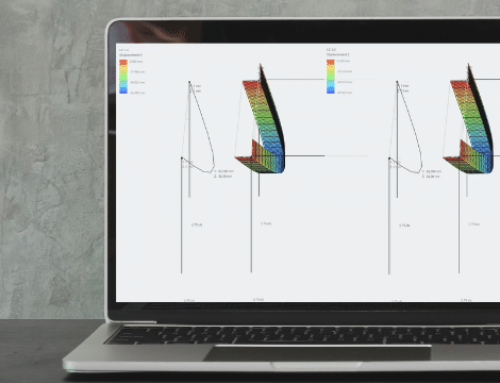

One of the most important considerations when designing a steel connection is to design based on the internal forces that the connection is expected to transmit. Connections are classified as axial, shear (semi-rigid), or moment (rigid) connections based on the primary load that the connection is to carry. Connections however are most typically expected to carry two or more of these loads. These include:- Moment Connections: a joint that allows the transfer of bending moment forces between a column and beam

- Shear Connections: a joint that allows for the transfer of shear forces between two members

- Axial Connections: primarily carry axial loads and include splices, bracing, truss connections, and hangers.

Find out more about axial, shear, and moment connections with some illustrated examples.

Find out more about axial, shear, and moment connections with some illustrated examples.

Type of structural elements that make up the connections

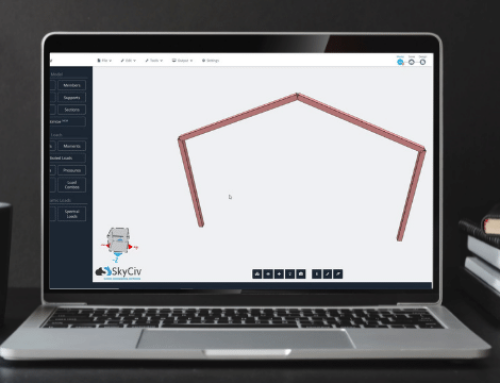

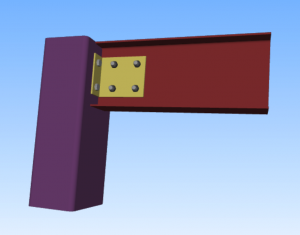

The type of structural element(s) that make up a steel connection is a common classification. There are many different types of structural elements, and the various placements to the structural members results in many different connection types. The most common structural elements are angles and plates. Angles can be placed at an i-beam's web (web angle), or at the i-beam's flange (seat angle), and plates can as well in a similar way (resulting in web plates and flange plates). Find out more about the different types here.Members being joined

The classification of steel connections is also commonly made to the structural members that they are to connect. In fact, the consideration for connecting columns and beams should act as one of the primary considerations when needing to design a steel connection. The common configurations include:- Beam to Column Connections: the most prevalent configuration in structural engineering

- Beam to Beam Connections: typically come in two types - one involves a primary beam connecting to an adjacent secondary beam, while the other utilizes a beam splice for linearly aligned members

- Column to Column Connections: usually accomplished with the use of a column splice.

- Column Base Plate Connections: link between a column and concrete pedestal.

Method of erection

The method and location of erection of the steel connection is one type of classification that makes a big impact on the cost of the project. In general, field operations are more costly than shop operations. For this reason, the installation of steel connections is usually a combination of both to reduce the overall cost. Find out more about field and shop operations in our article.

William Kuang

Engineer and Software Developer

BEng Mechanical (Hons1)

LinkedIn

Engineer and Software Developer

BEng Mechanical (Hons1)