Lifting Lug Design Calculator

A lifting lug (also known as a lug or a pad eye) is a device commonly found on a range of equipment and structures, including storage tanks, shipping containers, and other vessels that need to be lifted and moved around.

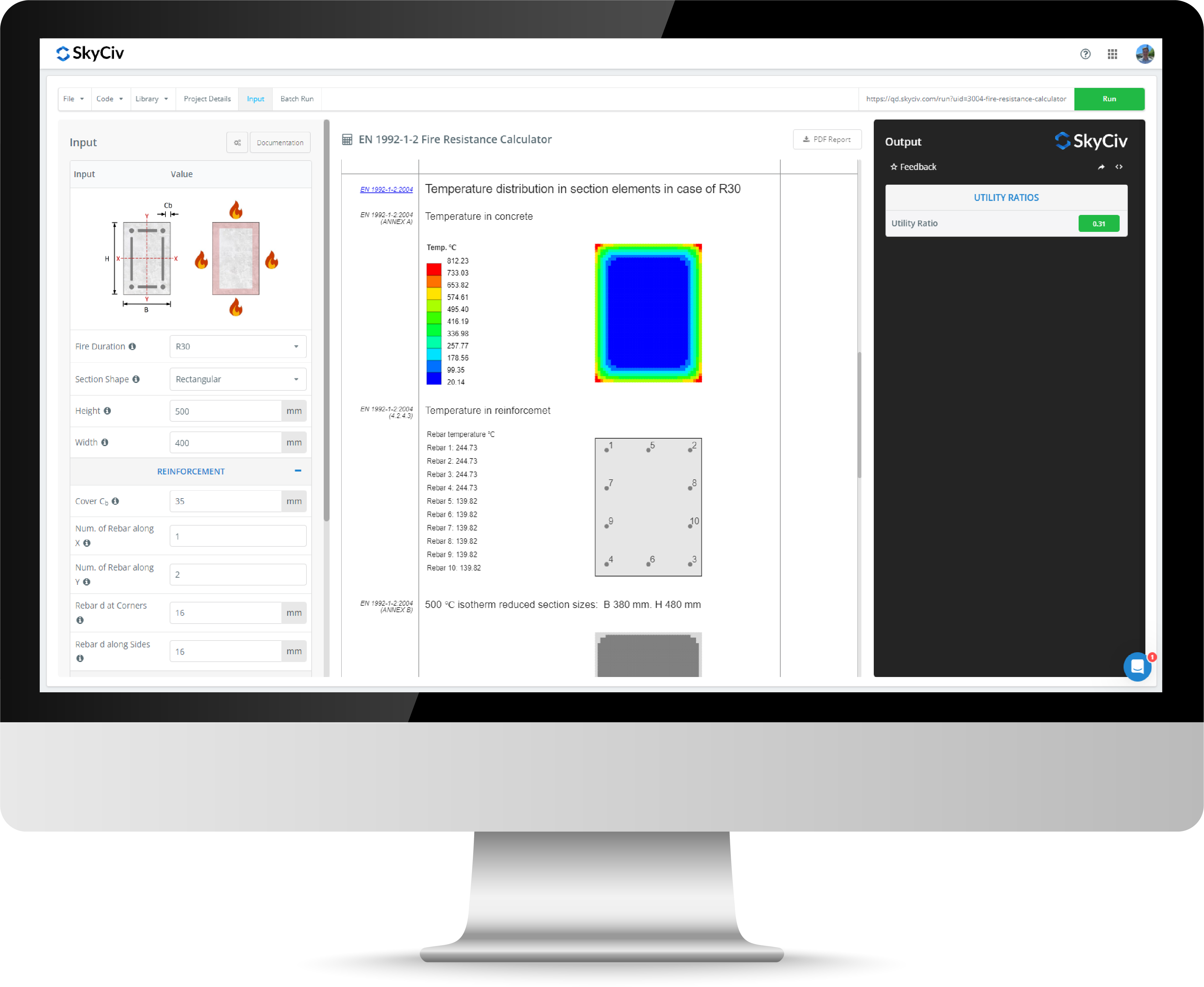

When analyzing and designing lifting lugs, various modes of failure must be checked. The SkyCiv Lifting Lug Quick Design allows you to design lifting lugs of various dimensions and loading based on the following standards:

- AISC 360-16 Lifting Lug Design

- AS 4100:2020 Lifting Lug Design

The lifting lug capacities calculated in this calculator include maximum tension capacity, maximum bearing capacity, maximum shear capacity, maximum pin tear-out capacity, and weld capacity.

About the Lifting Lug Design Calculator

What is a Lifting Lug?

In its most basic form lifting lug is a metal plate with a hole in it attached to equipment like shipping containers, equipment skids, structural elements, various types of tanks, and more.

As the name suggests, lifting lugs enable things to be lifted and moved around on construction or other industrial sites. Therefore, they must be designed so that the hole is resistant to bearing and shear failure, and the welds are strong enough to resist stresses in the plate and neck of the lifting lug.

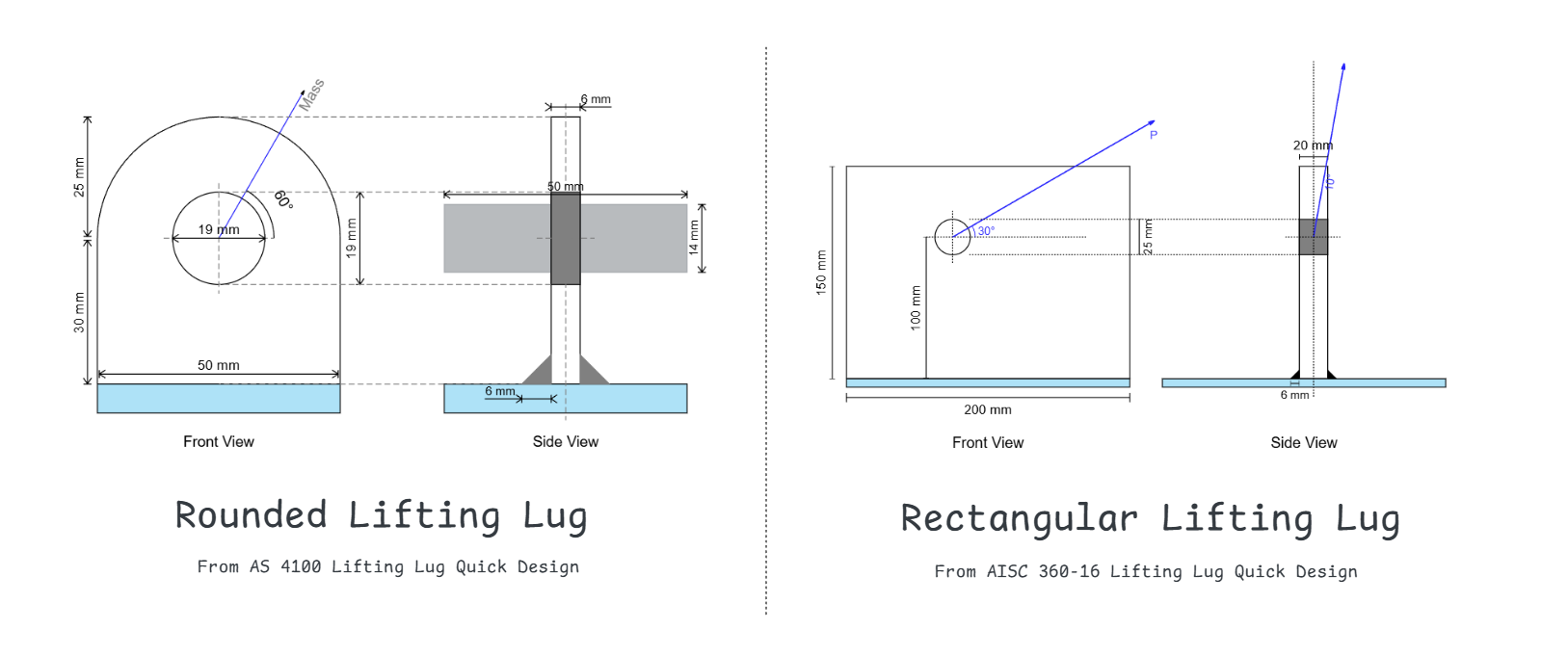

Lifting lugs are commonly made of carbon, structural, or high-strength steel, depending on the exact nature of the lifting application. The plate can typically be as thin as 12mm (3/8in) for light loads and upwards of 50mm (2’’ inches) for heavy industrial loads. The hole diameter will also range based on the plate size and the size of the eyebolt used when lifting. Generally, the width and height of the lifting lug will be factors of the hole size, for example, the width maybe 2-3 times the hole diameter and the height 3-4 times the hole diameter. Some examples of lifting lug diagrams can be seen below.

Design of Lifting Lugs

AISC 360 Lifting Lug Quick Design

The AISC 360 Quick Design Lifting Lug module completes the following design capacity checks:

- Maximum Tension Capacity

- Maximum Bearing Capacity

- Maximum Shear Capacity

- Maximum Pin Tear Out Capacity

- Weld Capacity

Currently, the lifting lug calculation is based on the E49XX electrode. The AISC 360 Lifting Lug Quick Design supports only limited calculation of eccentric in-plane moments.

AS 4100:2020 Lifting Lug Design

The AS 4100:2020 Quick Design Lifting Lug module completes the following design capacity checks:

- Tension in Lug

- Shear in Lug

- Bearing in Lug

- *Shear and Tension in Weld

Depending on the static lifting weight, lifting angle, and dynamic amplification factor, the net action of forces acting on the lug is calculated. The lug capacities are then worked out in tension (yielding), shear (horizontal and vertical), and bearing.

The same are compared concerning the design action of forces, and the utilisation factors are evaluated against each mode of failure for tension, shear, and bearing, and compared to the design action of forces. Weld capacity is also checked for Shear and Tension.

The AS 4100 Lifting Lug Quick Design can take the Dynamic Amplification Factor (DAF) as an input. This factor is to account for dynamic effects that often arise because structures respond differently to moving or changing loads compared to static loads. The DAF helps translate the impact of dynamic loads into a format that can be handled within the static load calculations by amplifying the load to reflect the increased stresses and strains on the lifting lug.

Does the calculator consider lifting angles?

Yes, the Quick Design Lifting Lug Calculator can consider the Maximum Angles of Load can be provided as an input, which will be used ultimately for checking the weld strength.

Accessing the AS 4100:2020 Lifting Lug Design Software

SkyCiv also allows for the design of lifting lugs as per Australian Standard 4100. To access this version, please switch design codes using the flag icon at the top of the input panel. The AS 4100 lifting lug design tool allows you to calculate the capacities of a steel lifting lug based on its length, width & height. The capacities calculated include bearing, shear, bending, and weld capacity.

Disclaimer: Lifting Lug Design

The SkyCiv Lifting Lug Calculator tool is for the preliminary design of lifting lugs as per AISC only. When designing lifting lugs, additional factors, such as attachment stress, may need to be considered to avoid distorting and integrity of the vessel during lifting operations.

In scenarios where attachment stress is significant, it is strongly advised that engineers consult additional sources beyond the initial lifting lug calculations provided by this tool. Further design checks should involve performing checks with well-meshed finite element analysis, consulting qualified expert engineers, and conforming to all relevant local design codes.

Lifting Lug Software FAQs

What design code are this calculations based on?

This lifting lug calculations in this tool are based on the American Institute of Steel Construction (AISC) code as well as the AS 4100:2020 code.

What units are supported in the lifting lug tool?

The reporting produced by the calculator only supports metric units, but inputs can be added in imperial units.

What electrode is the calculator based on?

Currently, the calculation is based on the E49XX electrode only.

Can these calculations be used with any equipment?

The lifting plate configuration is applicable for almost any type/part of equipment being lifted. Commonly, this includes equipment such as skids used in the oil, gas, and piping industries.