SkyCiv and its modules are a powerful set of tools from which users can model, analyze, and design. Due to its intuitive and powerful 3D modeling and analytical capabilities, SkyCiv 3D allows for multitudes of variability for structural engineering projects. In the case of John Marhoefer, P.E., Managing Partner of Entech Innovative Engineering, the capabilities of SkyCiv provided a robust and adaptive platform for important engineering decisions related to a large climbing structure for children built within the Ronald Reagan Building, the new location of the National Children’s Museum in Washington, D.C. To read more about the Dream Machine and other specialty engineering projects, check out the Entech Innovative Engineering website.

Dream Machine Project, National Children’s Museum, Washington, D.C.

Type: Institutional

Engineer: Entech Innovative Engineering

Entech Innovative Engineering, founded by John in 1993, is a design, engineer and build company providing specialized structures and mechatronics for various industry, science, art, and entertainment clients. Building a special climbing structure for the National Children’s Museum on schedule and within budget, John needed a powerful structural engineering tool to make founded engineering decisions with alacrity. John had some pretty strong words regarding the SkyCiv platform:

“SkyCiv is well designed for the practicing engineer, including straightforward interface and clear results with very friendly and adaptive features,”

“Using SkyCiv we are able to develop, optimize, share and document our engineering designs quickly and efficiently. SkyCiv has become an indispensable tool for us.”

About the Project

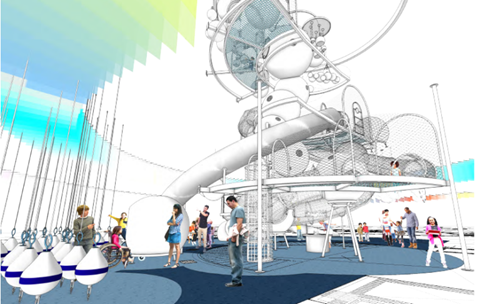

Located at 1300 Pennsylvania Avenue, Washington D.C., the new location for the National Children’s Museum is between the White House and the U.S. Capitol Building. The Dream Machine is a three-story children’s climbing structure, pictured in Figure 1. The creative idea came from Gyroscope Studios of Oakland, California, and is the most iconic statement of the museum. It is the most high profile structure that all the visiting children see and want to interact with. The interaction makes the children want to come back, time and time again.

While the Gyroscope team defined the creative intent, it became the job of Entech Innovative Engineering to develop the creative design into an engineered and build-able structure on time and within budget.

Figure 1: National Children’s Museum Dream Machine Design Intent Drawing Courtesy Gyroscope Inc.

The Challenge

The National Children’s Museum occupies approximately 25,000 square feet of the existing General Services Administration (GSA) Ronald Reagan Building. Originally completed in 1997, it is the second largest government building in the country. The creative design was developed without serious consideration of the physical constraints and demands of the engineered structure. To work in the tenant’s space, Entech needed to engineer a solution that met the creative and operational objectives while accommodating the demands and capacities of pre-existing space. This required a considerable amount of iterative engineered design. In more than one instance, as new design developed, new constraints emerged requiring ongoing design re-configurations.

Figure 2 and the cover image are views of the installed Dream Machine from the ground level looking up. Curved decks, crawl tubes and pods are visible in the photograph.

Figure 2: Engineered and Built Dream Machine

The Dream Machine design called for unorthodox 3D design details and non-orthogonal framing that SkyCiv was able to accommodate. To that end, John adds:

“SkyCiv is a powerful and readily accessible analytical and design tool. The relative simplicity of the platform belies the power it can provide. SkyCiv was easily able to handle atypical geometries and curved members and surfaces which helped us make important design and detailing decisions to assist in maintaining our budget and schedule targets.”

Using SkyCiv, the Entech team was able to accommodate design changes expeditiously, knowing that the structural developments each time met the engineering requirements for them.

How it was Designed

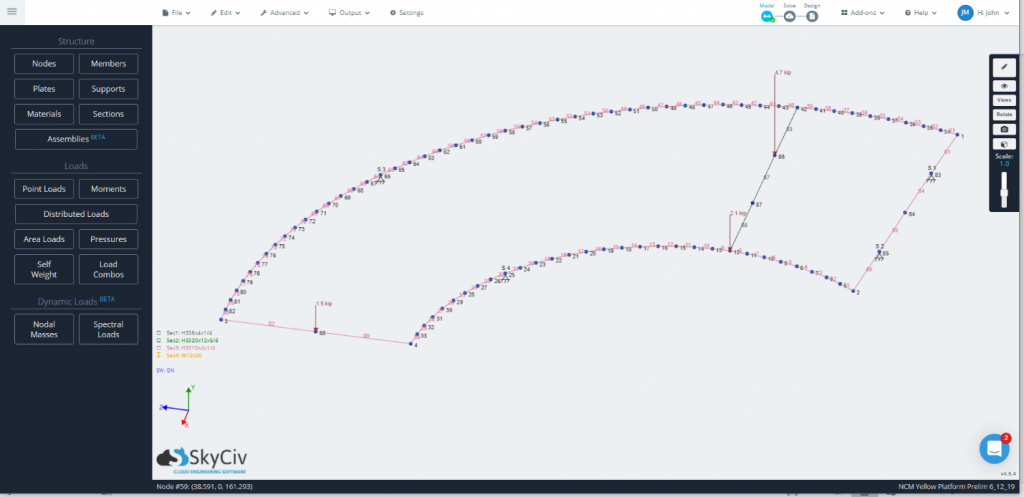

Entech was able to model each of the major assemblies that comprise the system as well as separate models where necessary to investigate local details. The SkyCiv curved member and surface modules were particularly of use in determining designs optimized for constructability.

Figure 3: SkyCiv Interim Data for Curved Deck Preliminary Member Analysis/Sizing

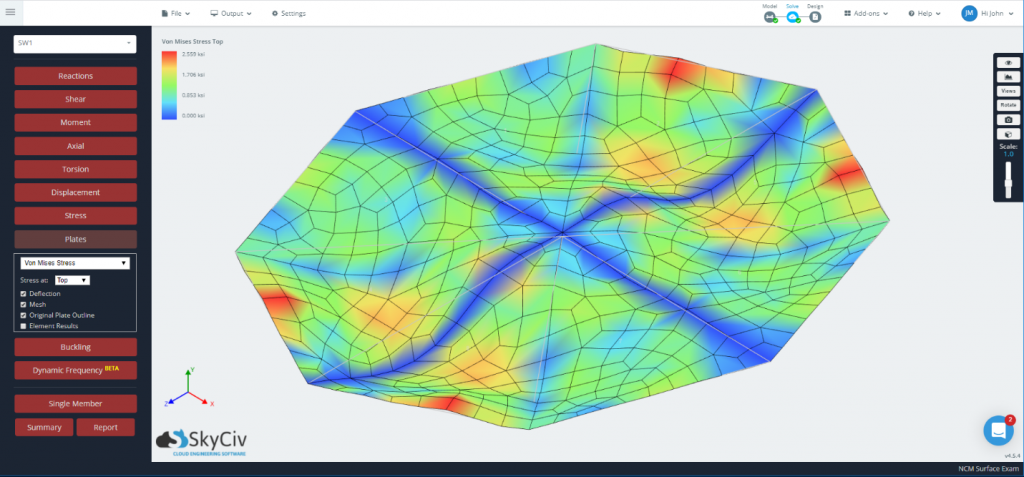

Certain surface areas of the build required analytical support and SkyCiv surface modules provided an easy way to model and obtain results. Figure 4 depicts an instance of the iterative design process:

Figure 4: SkyCiv Plate/Surface Data Analysis for Framing Optimization

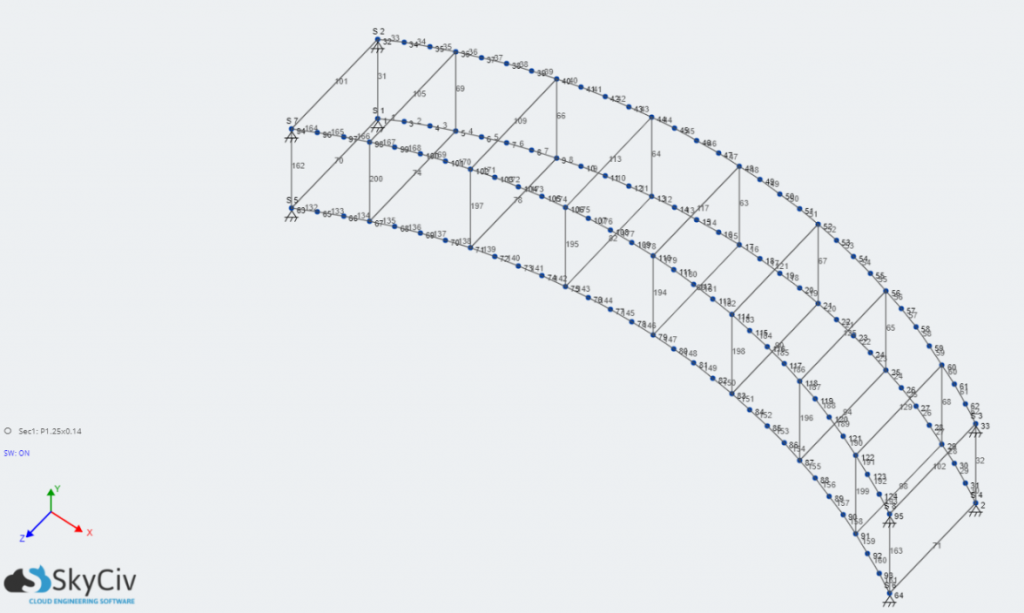

The Dream Machine includes a considerable number of climbing crawl tubes where children and adults can ascend and descend the three-story tower. SkyCiv made a global analysis of the proposed design easily possible, and Figure 5 illustrates some of the design approach.

Figure 5: SkyCiv Modeling of Crawl Tube Design

The documentation capability of SkyCiv, including the “hand calculation” feature, was an important part of the engineering quality assurance that went into the design. SkyCiv offers a multitude of design modules and features that improve design decisions by being able to quickly assess different form factors and assemblies. Furthermore, the strong and easily accessible tutorials within the SkyCiv ecosystem made integrating new design team members straightforward and quickly productive.

How SkyCiv Helped

When asked how SkyCiv helped, John’s answer included several benefits, including the ease of understanding the tools and interface, the clarity of the results, the cloud-based aspect, the on-line educational tutorials and the customer service.

Of those, John said SkyCiv’s accessibility, the on-line tutorials and understandable, usable GUI’s and robustness of the design modules underpins Entech’s continued commitment to SkyCiv:

“I hired several new engineers recently and while none had prior experience with SkyCiv, all of them within a short period of time were highly productive with its use”

“Using SkyCiv, we were able to develop a robust, buildable, cost effective iconic structure for the client and document all of our engineering decisions clearly and concisely”

Want to see if SkyCiv is a good fit for your practice?