About QuickFrames USA

QuickFrames USA manufactures steel components for the commercial construction industry. As the leader in engineered structural support frames, QuickFrames proudly holds its distinction as the only patented, bolt-on, adjustable alternative to welded-in roof frames. Their original product line – an adjustable roof framing system to support RTUs on buildings with open-web joists – has grown into multiple lines of framing products spanning nearly all types of commercial roofing and floor support systems.

The Problem

The Solution

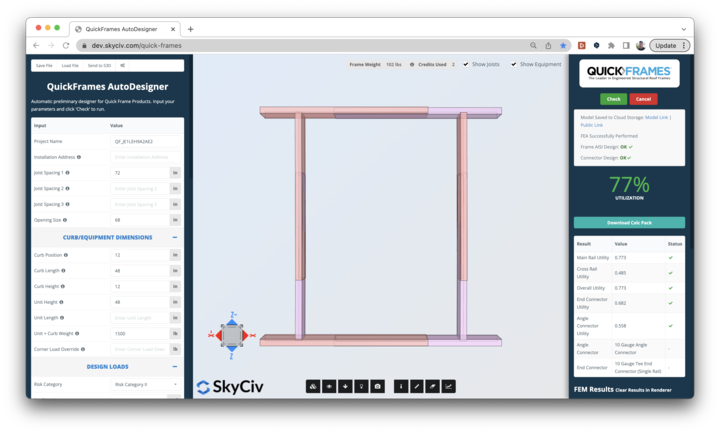

In an effort to tackle this problem, SkyCiv collaborated with QuickFrames to develop the AutoDesigner utilizing our API technology.

QuickFrames products rely on cold-formed steel sections that are easily expanded or contracted depending on the client’s needs. So there were three main aspects to the solution – Loading, Worst Case Testing and Optimization.

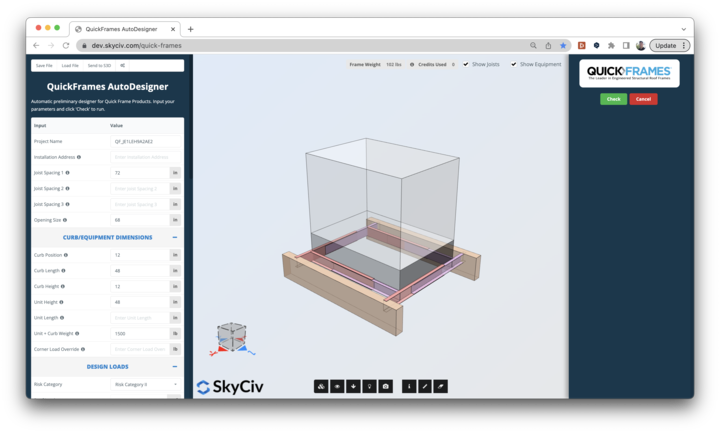

For one, the loading was site-specific and a time-consuming part of the process. The Configurator automatically calculates and applies necessary wind, snow and seismic loads and generates a ready-made analysis model with appropriate load combinations. The 3D visualisation displays this analysis model in real-time, allowing both the client and engineer to review the proposed design.

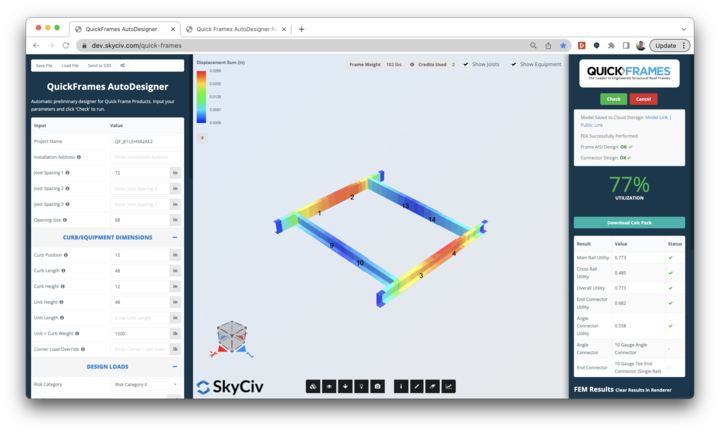

In addition, it was important to consider the worst case, as it wasn’t always clear what position the client was going to use the product – so it had to be designed accordingly. The solution automatically tests the different possible configurations, tests each scenario as per AISI requirements and then finalizes the design including connectors.

A final piece being added is the ability to optimize the design through different gages to test the most efficient design. All automated, in a matter of minutes.

Get in touch with SkyCiv API team to learn more about automating your tasks using technology:

The Key Attributes of the AutoDesigner

- SkyCiv Renderer – One of the most noticeable features of the AutoDesigner is the real-time 3D visualisation of the structure.

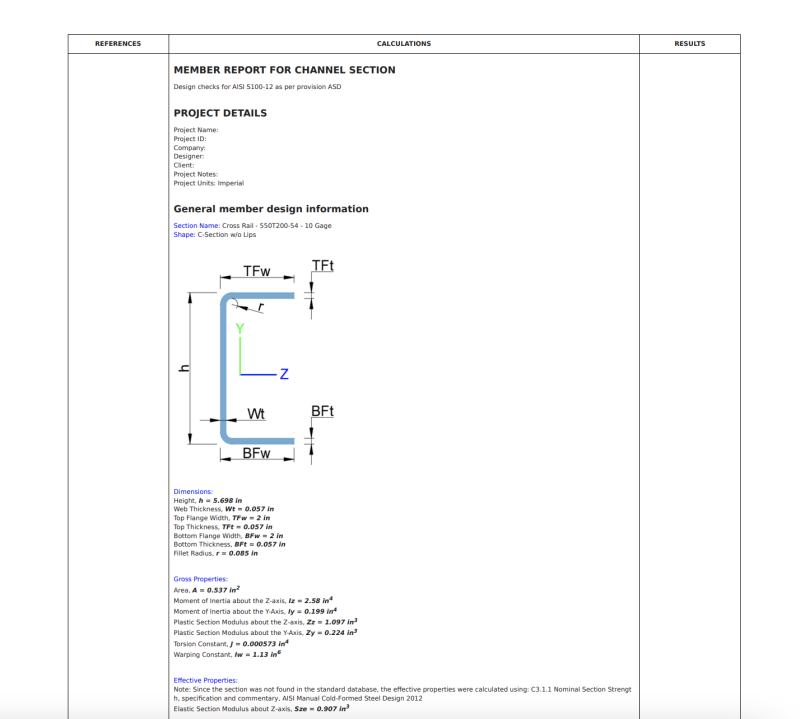

- Reporting – the final design report combines all of the necessary design information for the engineer to review. It is customised to show the right amount of information, including loading calcs, summary of FEA results and step-by-step calculations of the AISI governing member design

- SkyCiv FEA via an API – utilising FEA to calculate the accurate design forces on the frame is paramount to an accurate and efficient design. It enables the user to test 30+ load combinations and design to a finer line as a proper analysis has been performed.

- SkyCiv Design Checks via an API – using both custom and standard design calculations to ensure the engineer is designing to code with a high degree of precision.

About SkyCiv API

SkyCiv API allows businesses to generate a model, run an analysis, design checks and respond with a simple pass/fail result, with a single click and without the need for any visual or graphical user input.

Visit our API technology product page or download the ebook below for more information. Alternatively, contact us to discuss a customized solution for your business.