选择初始部分

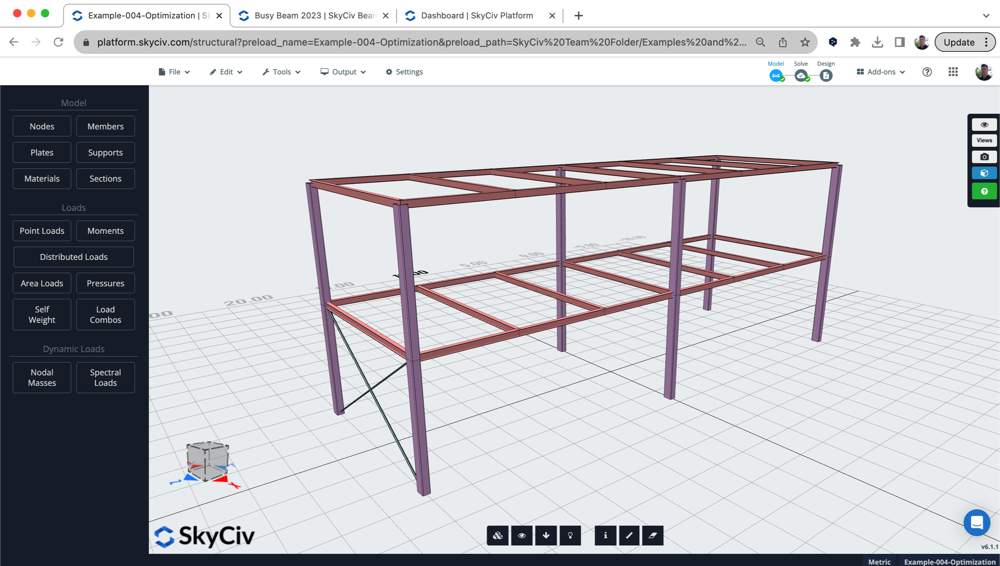

首先对您常用的结构进行建模, 今天我们将回顾一个具有通用梁的模型, 柱的高速钢截面和支撑的等角截面. 您几乎可以从您喜欢的任何部分开始, 但是我们通常建议选择您最认为可行的部分. 这是我们将要优化的模型:

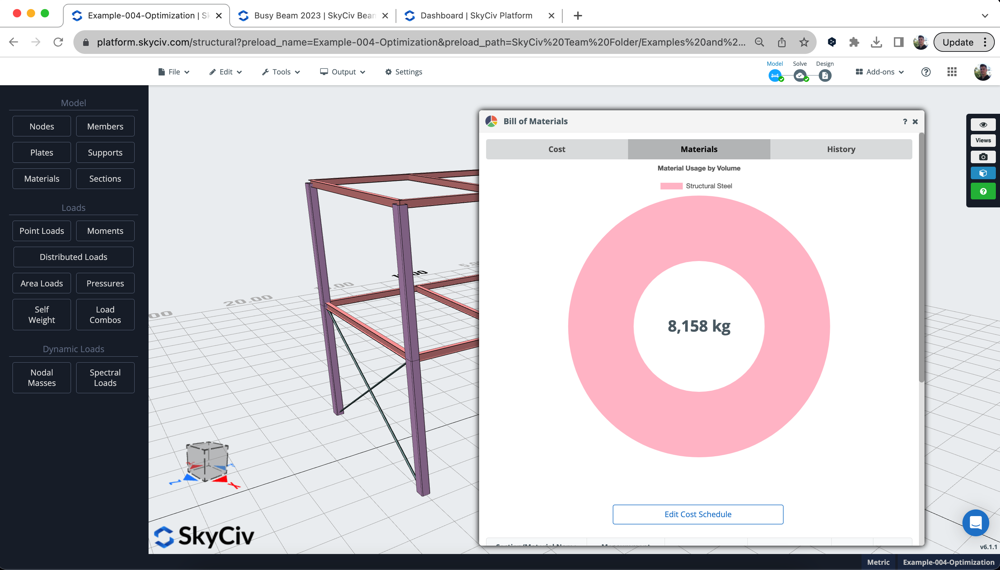

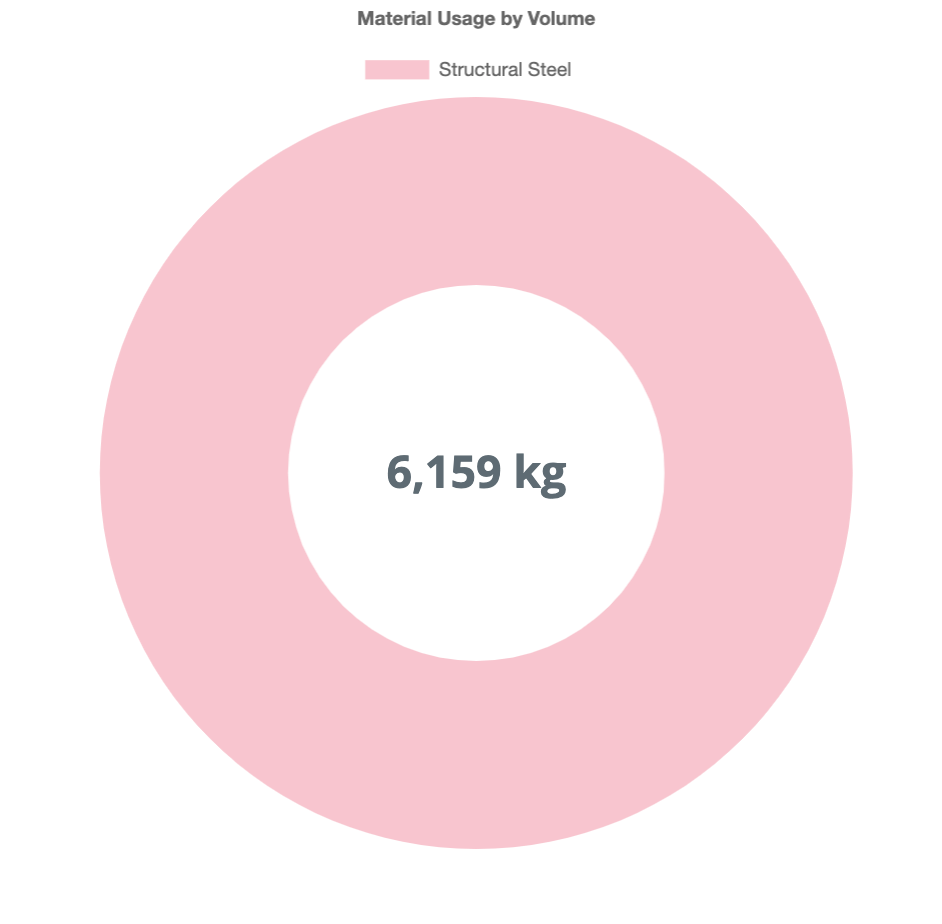

该模型具有荷载组合, 活荷载/死荷载/风荷载和已设置的适当约束. 我们还想看看这个设计的最初材料使用情况. 我们使用 物料清单应用程序 计算初始设计中使用的材料量:

审查设计结果 + 设置优化设置

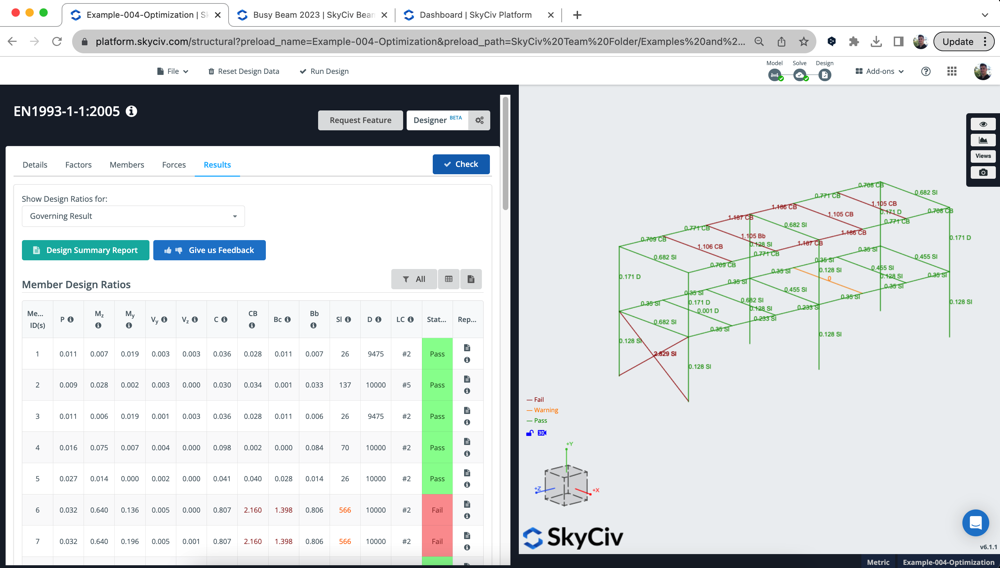

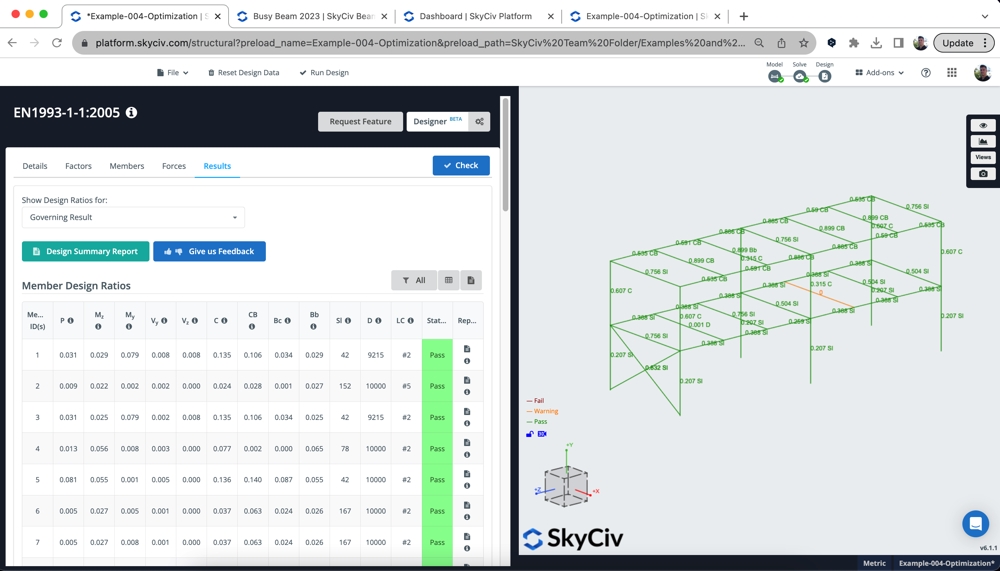

通过运行模型的设计检查来检查设计最初的位置通常是一个好主意. 在这个例子中, 我们将使用 EUROCODE 用于钢结构设计检查, 但您可以轻松地运行以下设计检查:

- 钢 – AISC, CSA, 作为, BS, 是

- 木材 – NDS, AS1720

- 冷弯钢 – AISI, AS4600

查看结果后, 我们可以看到以下内容:

- 通用梁: 失败了, 但只有一点点, 效用比率约为 110%. 我们想要优化这些,让它们通过

- 高速钢柱: 都过去了, 但效用很低 (23%) 所以我们觉得我们可以优化和减少这里使用的材料

- 支撑杆件: 这些 EA 部分都失败了, 效用约为 300%. 我们想要找到通过设计要求的最优截面

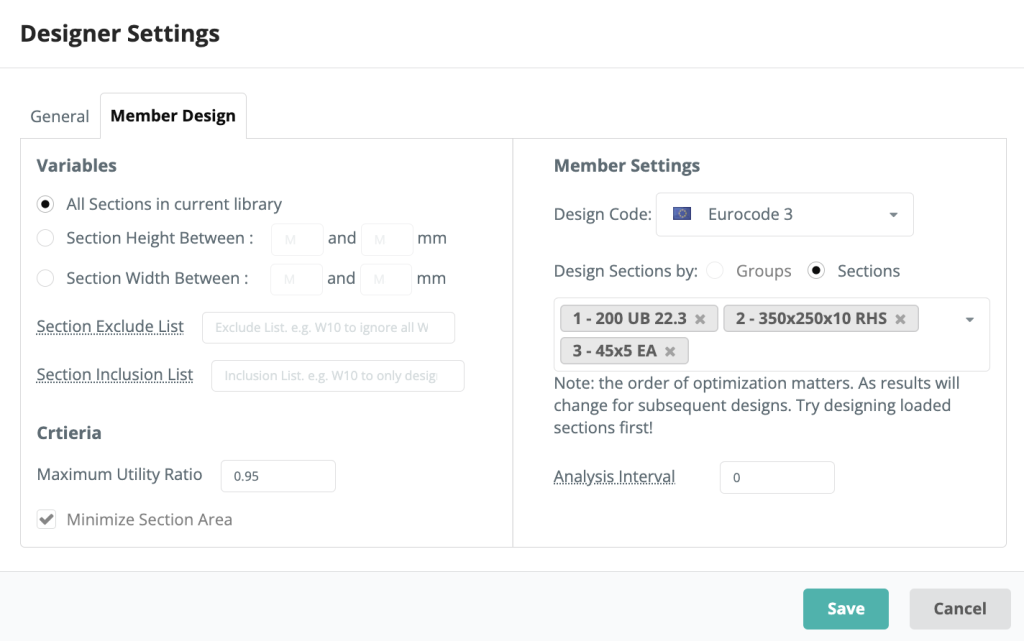

相应地, 我们想使用具有以下设置的设计器运行优化. 我们想要设计所有 3 截面, 分析间隔设置为 0 (这意味着测试每个部分后不会重新运行分析):

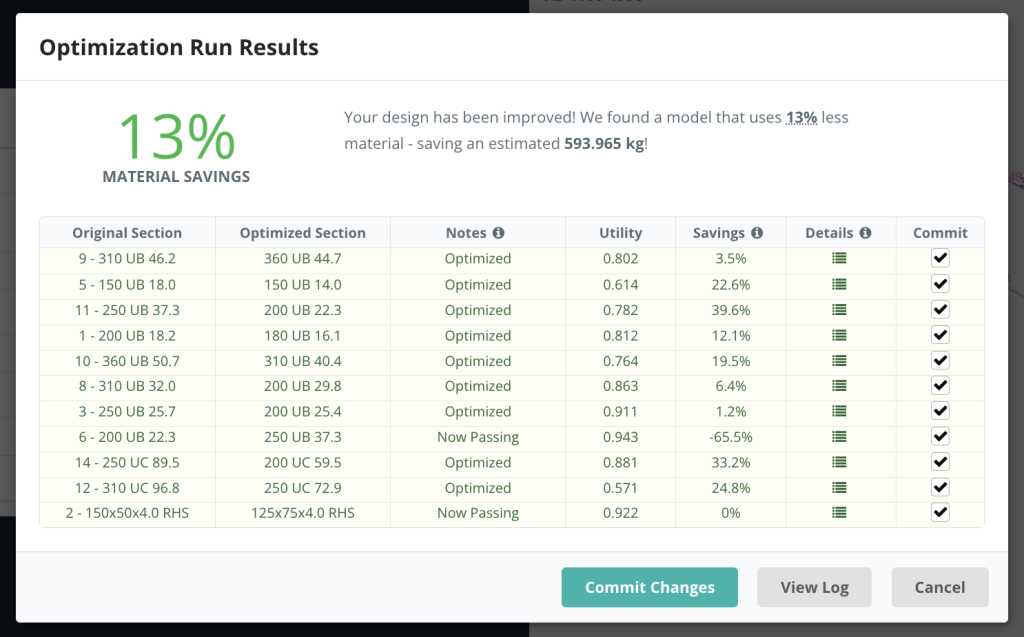

审查设计者的结果

一旦设计师运行, 我们收到以下弹出窗口 – 一目了然地显示所选的最佳部分:

注意: 上面的截图显示了最新的UI. 结果来自不同的模型,与本教程中的结果不匹配

设计师能够为所有部分找到合格的结果. 结果如下:

- 部分 1 略有增加, 找到了一个可行的解决方案 94.9% 公用事业

- 部分 2 节占用大幅减少, 并能够找到一个可行的部分 88.6% 公用事业

- 部分 3 之前失败过, 现在经过一个更大的部分,但在以下位置进行了优化 83.2%

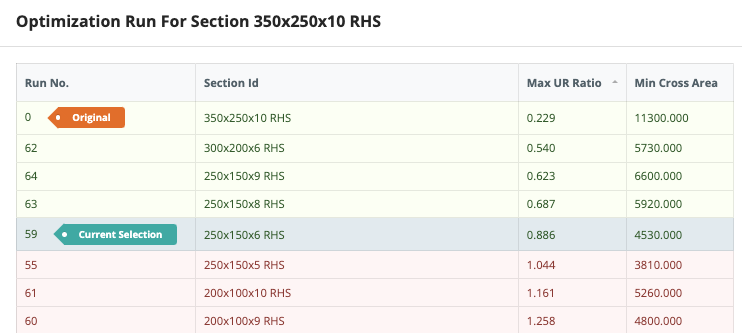

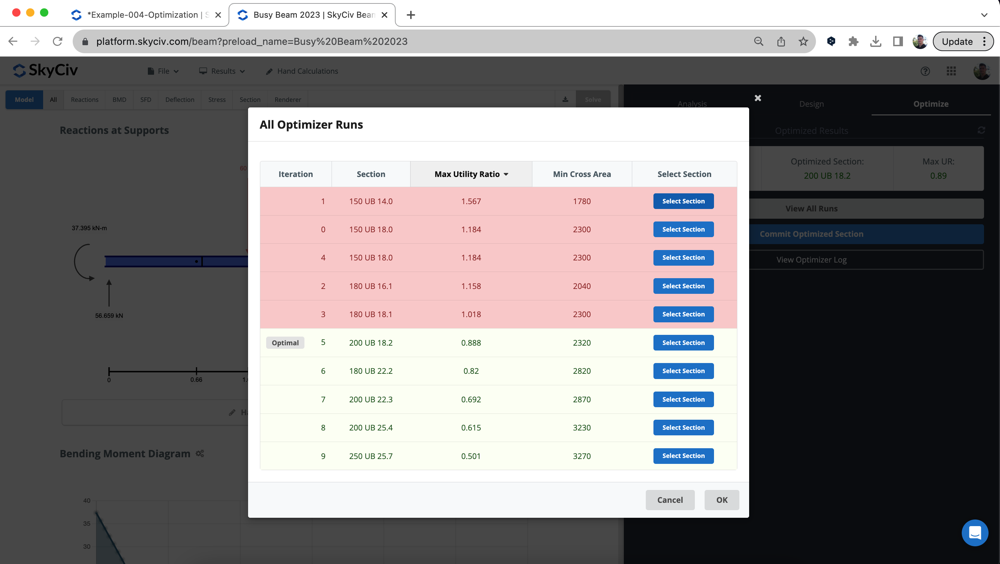

我们还可以通过单击查看每个部分的所有运行 迭代 图标. 这将显示有关所有测试部分的更多信息. 例如, 正在查看部分 2 上面我们可以看到它只是之前的 22.9% 已利用, 并且不在 88.6%:

提交设计师建议的部分

一旦您对建议的部分感到满意, 点击 提交更改. 然后软件将重新求解模型并重新检查各个部分. 在我们的视频中, 您会看到结果与部分设计器不匹配 1. 这是因为 分析区间 被设置为 0 – 分析结果的含义 (特别偏转) 优化过程中未更新.

所以, 我们重新运行了 设计师 – 这次只是部分 1 并将分析间隔设置为 1. 再次提交更改后, 我们有一个完全设计的模型,所有部分都根据该设计标准进行了优化:

我们现在还可以使用第一步中使用的物料清单应用程序来查看成本节省情况, 这表明我们将结构模型减少了约2,000kg – 导致几乎 25% 材料较少.

使用 SkyCiv Beam 进行优化

我们还可以优化单光束, 使用 SkyCiv Beam 产品. 结合上面的设计师, 我们能够快速、简单地获得最佳部分的结果. 我们可以这样做 3 简单的步骤:

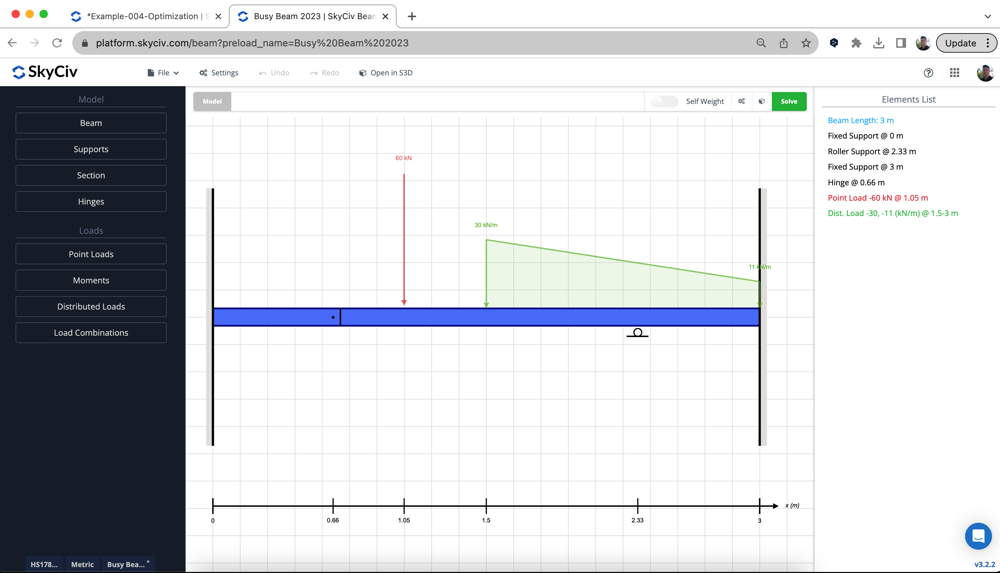

1. 建立你的模型 – 像往常一样构建模型, 在本例中,我们使用了加拿大 HSS 截面:

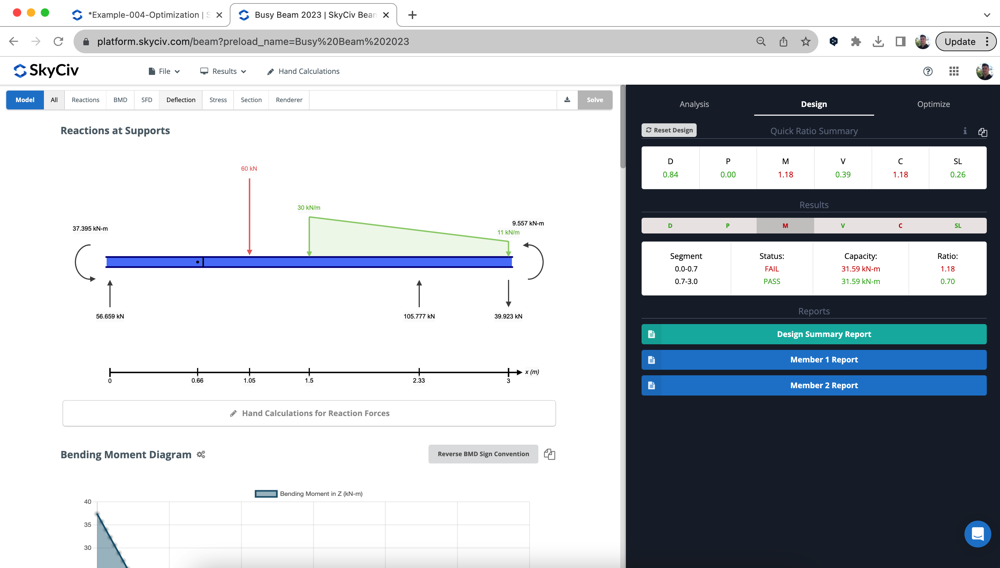

2. 审查初步结果 – 运行设计 (根据本例中的 CSA S16) 看看我们的设计最初在哪里. 在下面的例子中, 该部分失败约 20%:

3. 运行设计器 – 在下面运行设计器 优化 与您想要的部分并查看您的结果. 已经选择了最佳部分, 准备好致力于您的模型:

常问问题

我们这里有两个建议:

- 大型型号 – 将分析间隔设置为 0 – 这会运行得更快并返回一些非常接近的结果. 然而, 结果可能不匹配, 因此可能需要第二次重新运行某个部分

- 较小的型号 – 将分析间隔设置为 1 – 这样您就可以获得最准确的结果,因为我们在每个横截面之间重新运行求解器

- 中等大小 – 设置分析间隔 t0 5 – 这将平衡对准确性和速度的需求.

Designer支持S3D中的所有成员设计模块, 包含:

- 钢 – AISC, CSA, 作为, BS, 是

- 木材 – NDS, AS1720

- 冷弯钢 – AISI, AS4600

对于 SkyCiv 光束, 上述所有的, 除风能模块外, 受到支持.